Article re-posted with permission from Parker Hannifin Sealing & Shielding Team.

Original content can be found on Parker’s Website and was written by Alan Wiedmeyer, application engineer, Parker Engineered Polymer Systems Division.

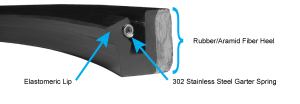

Clipper® Oil Seals are one of the Parker Engineered Polymer Systems (EPS) Division's most widely used rotary seal products. They are an effective solution – especially when used as direct replacements for traditional metal case seals. This is a testament to their precision-molded rubber/aramid fiber heel construction which eliminates the metal case (see image above). In this blog we will review the benefits of using Clipper® seal profiles as direct replacements for metal case seals:

Clipper® Oil Seals are one of the Parker Engineered Polymer Systems (EPS) Division's most widely used rotary seal products. They are an effective solution – especially when used as direct replacements for traditional metal case seals. This is a testament to their precision-molded rubber/aramid fiber heel construction which eliminates the metal case (see image above). In this blog we will review the benefits of using Clipper® seal profiles as direct replacements for metal case seals:

1. Improved sealing in an imperfect housing

The composite rubber/aramid fiber heel provides a gasket-like seal for improved sealing against the bore. The surface conditions of bore housings are frequently riddled with imperfections due to damage during improper seal installation and removal, or simply due to cost sensitivity in their original manufacture. Metal can seals lack the ability to conform to such imperfections, frequently necessitating the use of supplemental gaskets or bore sealants during installation to prevent bore leakage.

2. No need for compression or bore plates

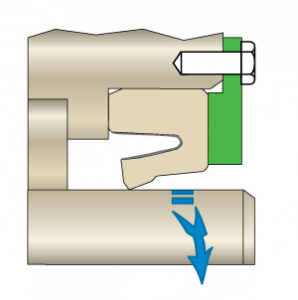

The outside diameter of the flexible, composite elastomer/aramid fiber heel is slightly oversized to create a tight interference press fit. The tight fit and compression-set-resistant heel construction eliminate the necessity of compression plates for bore retention1. It’s essential to note that bore plates (shown in green) can cost as much as $100 per inch of shaft diameter because of additional part cost and added assembly time.

The outside diameter of the flexible, composite elastomer/aramid fiber heel is slightly oversized to create a tight interference press fit. The tight fit and compression-set-resistant heel construction eliminate the necessity of compression plates for bore retention1. It’s essential to note that bore plates (shown in green) can cost as much as $100 per inch of shaft diameter because of additional part cost and added assembly time.

3. Corrosion-resistant

Clipper seals have a composite elastomer/aramid fiber heel and rubber elastomeric lip so there is no concern for rust or corrosion. The only metal component is a 302 stainless steel garter spring. The stainless spring handles higher operating temperatures and resists rust/corrosion better than carbon steel springs used in other rotary shaft seals.

4. Durable, one-piece molded construction

The Clipper Oil Seal features one-piece molded construction across its entire available size range (0.25” to 92”+ shaft diameters). This molding process is more robust as compared to metal case rotary seals constructed from multiple components that are glued and/or crimped together during assembly.

5. Resistant to issues arising from thermal expansion

Metal case seals are prone to sealing complications brought on by thermal expansion. As an example, consider what happens when interfacing a carbon steel metal case seal with aluminum housing in applications where large rapid temperature swings occur. Aluminum housings will expand at a different rate than the carbon steel case of the rotary lip seal; leaving you vulnerable to bore retention issues and/or failure due to leakage from the housing/seal OD interface.

6. Easy, damage-free installation

Clipper’s flexible, rubber heel prevents seal damage and component damage during installation. Seal installation, aided by proper chamfering, requires only finger pressure to start the seal into the housing, followed by light tapping with a soft-faced mallet until flush. Issues associated with installing rigid metal cans, such as damage due to cocking, are avoided.  To further ease installation and save time, because the outer diameter conforms to bore imperfections as mentioned earlier, there’s no need to add -- or wait for drying time of -- bore sealants.

To further ease installation and save time, because the outer diameter conforms to bore imperfections as mentioned earlier, there’s no need to add -- or wait for drying time of -- bore sealants.

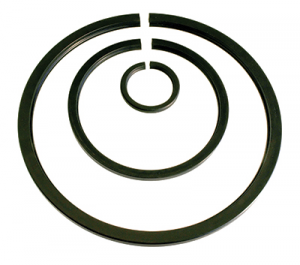

7. Splittable

Due to the Clipper Oil Seals non-metallic construction, Parker can produce certain profiles that have been precision split. Downtime due to seal replacement is minimized. There’s no need to uncouple or disassemble equipment since Split Clipper seals can be installed in place. For metal case variants, this is not an option. View the short video demonstrating the ease of installation here: Split Clipper Oil Seals Installation

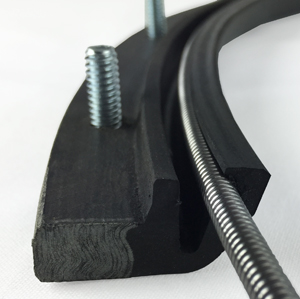

8. Highly customizable

The rubber molding process allows for greater customization to fit specific design envelopes. The addition of flanges, buttons, mounting and bolt holes, etc. are all possible.

The rubber molding process allows for greater customization to fit specific design envelopes. The addition of flanges, buttons, mounting and bolt holes, etc. are all possible.

9. Fast delivery

Non-stock items can be produced and delivered faster than metal case seals. Seal production of Clipper’s composite rubber design is not hindered by long lead times commonly experienced with the fabrication or procurement of metal components. Clipper Oil Seals 14” in diameter and smaller typically ship within 10 days.

10. Made in the USA

Since all Clipper Oil Seals are made in the USA, the supply chain is simplified. Procurement difficulties due to global import or tariff variables are non-existent.

Gallagher Fluid Seals is an authorized distributor of Parker. To learn more about how Gallagher Fluid Seals can help you, contact our engineering department at 1-800-822-4063