Gallagher Fluid Seals is a Parker Distributor is proud to be proud to be one of the few premier distributors to qualify as a “Parker Seal Technology Center (STC)”.

Double Chamfer Radial Seals

More often than not, an O-ring makes for a great sealing element. They seal over a wide range of pressure, temperature and tolerance. Normally they require very little room, are readily available, and easily sourced. However, there are specific applications that may be better suited for an alternate type of seal, such as a double chamfer radial seal.

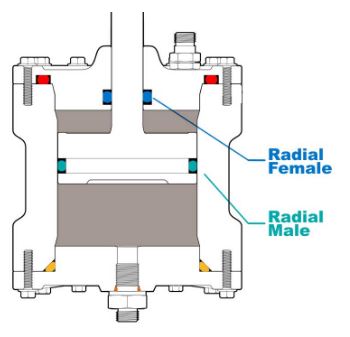

First, let’s clarify what exactly a radial seal is. Radial implies the seal is being compressed from inside to outside. Sometimes this type of sealing is called inner or outer sealing. It may also be called a rod or female seal, or a piston or male seal.

In essence, a radial seal is placed in a groove either around a piston, or in a groove inside a bore. Double chamfer radial seals will fit in both a male groove, around a piston, or in a female groove (inside a bore).

Unlike an O-ring, the cross section of the double chamfer radial seal has two flat sealing surfaces, and opposite of the groove, they are angled for easier installation.

Advantages of double chamfer radial seals:

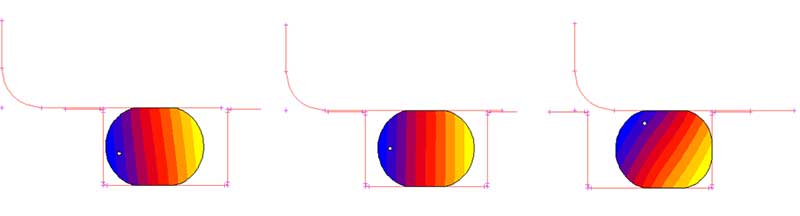

- When the O-ring fails by spiraling in a reciprocating application or during installation, the double chamfer seal is a good alternative. The wide, flat base of the double chamfer makes it resistant to rolling, and therefore, a solution for O-ring spiral failure. The FEA below demonstrates the O-ring rolling in a gland.

- High pressure or large clearance gap applications can result in an extruded O-ring. A common solution is to add a back-up ring as a support to the O-ring. The back-up ring is a great solution, however this can add complexity in several ways. One, it adds another item to the bill of materials. Second, the back-up can be difficult to install, resulting in damage. Finally if the back-up is forgotten or incorrectly assembled during installation, the O-ring will leak. A high pressure high temperature double chamfer radial seal replaces the O-ring and back-up combination with a single sealing solution. In addition, known issues with scarf cut back-up rings are the chance of the angled edge damaging the O-ring. By eliminating the scarfed back-up, we are eliminating a possible failure mode.

- A third advantage has to do with available groove space on the hardware. Standard O-rings require a specific groove depth and width, which can be difficult in tight locations or with limited hardware space. Since double chamfer radial seals are easily customized, they can be designed for a more shallow groove, and seal just as well as an O-ring. Double chamfer radial seals are easily customized in both size and material for most any application. For example, since the product is extruded rather than molded, the custom sizes will likely not need a costly mold and instead, use existing extrusion tooling configured for the desired size. And since the double chamfer radial seal is extruded rather than molded, there is no parting line on the finished product. This can be an advantage for gaseous or vacuum applications when even the smallest change in sealing surface finish will create a leak path.

Another feature of the double chamfer radial seal is the ability to color code the outer diameter (O.D.) or inner diameter (I.D.) for visibility of proper installation. This helps operators to easily see the seal is installed, which can be beneficial when a black O-ring is in a black housing. Double chamfer radial seals can have an inner diameter as small as .500” or have an outer diameter as large as 18” which means most every groove can retrofit from an O-ring. The seal height, also called wall, and width, also called cut, can also be adjusted.

Watch a short video on Double Chamfer Radial Seals:

The original content can be found on Parker's Sealing and Shielding blog.

To learn more about double chamfer radial seals and other Parker products, please contact Gallagher Fluid Seals. We will be happy to help you find your next sealing solution.