Small, nondescript and ostensibly unspectacular – it is often developments of this exact description that lead to groundbreaking innovations in the world of technology. The idea of manufacturing seal sleeves from leather scraps became the starting point in one of the most important developments in sealing technology: the Simmerring®. For 85 years, the Simmerring has been inseparable from the Freudenberg history of success, and, in Europe, its name has even become a synonym for (radial) shaft seal rings of every kind. Today the Simmerring is a high-tech product whose key functions go far beyond the sealing of the shaft against its housing.

The first Simmerring emerged in 1932. Consisting of a leather sleeve firmly built into a sheet metal housing, it immediately surpassed the preceding technology. Additional steps in its development, such as incorporating a worm spring and the impregnation of the leather with Acronal, brought valuable improvements in functionality. Freudenberg gradually solved the initial problems, such as low resistance to high temperatures and solvents. With the continued development of the Simmerring, Freudenberg became the world’s leading sealing specialist. In 1953 – 21 years after its ancestors first emerged – Simmerring production reached the 100-million mark.

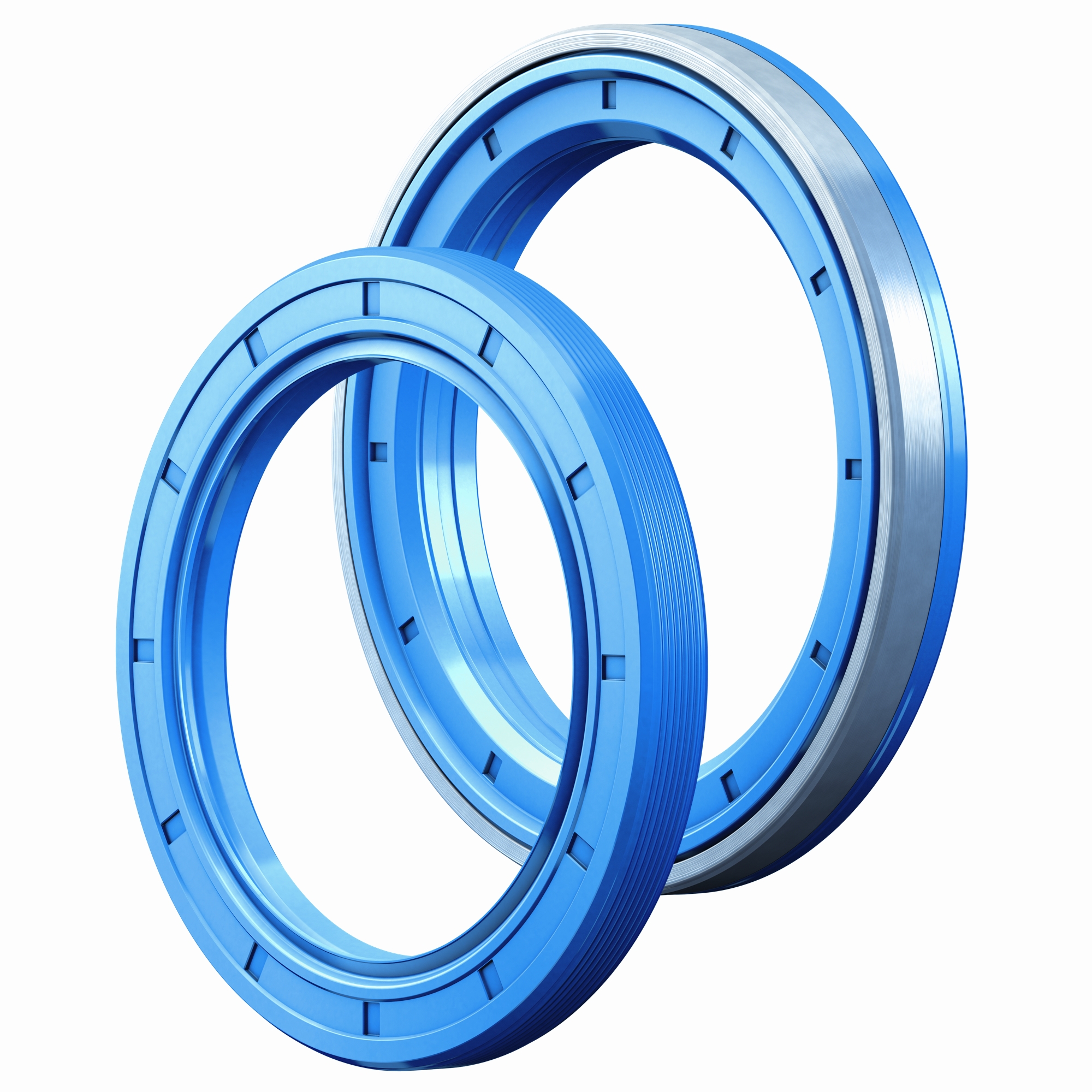

Equipped with a sleeve made of PTFE, chemically resistant and suitable for use in a temperature range of -40°C to 260°C, the Simmerring conquered the internal combustion engine in Europe and America in 1980. The next major step in its development provided even more performance characteristics far beyond its actual sealing functions. In 1997, Freudenberg developed a Simmerring with a multipole encoder. By interacting with sensors, it provides information about its position, from which precise data about rotational speeds and angles can be acquired – values of key importance to today’s assistance systems and engine management. The Simmerring with condition monitoring provides information about its own condition. The technology also makes the replacement of Simmerrings solely on the basis of maintenance schedules unnecessary. They also offer functional security in hybrid and electric vehicles thanks to their conductive nonwovens, which prevent the dangerous buildup of electrostatic charges between housings and shafts.

The Success Story Continues

Freudenberg laid the foundation of its success in the sealing field 85 years ago with the development of the Simmerring. Along with countless modifications, steady, ongoing development with an eye to efficiency, environmental protection and sustainability has led to breakthroughs in sealing technology and new, additional functions again and again. Nowadays, the right Simmerring is available for nearly every conceivable application. No end to its development is in sight either. Freudenberg will develop suitable Simmerrings for coming requirements as well.

More information on the 85-year history of the Simmerring can be found here >

This article has been reposted from Freudenberg’s NEWS section of their website.

Source Article: https://www.fst.com/press/2017/freudenberg-85yearssimmerring-press