Anyone who has ever enjoyed a fruit tea out of a mug that previously contained coffee knows the problem: taste transfer. It is an undesirable phenomenon during product changeovers in the food industry.

With Fluoroprene XP, a line of premium seal materials, Freudenberg has brought out an all-purpose weapon to handle steam sterilization, aggressive media used for cleaning in place (CIP) and sterilization in place (SIP), and high-fat concentrations. Until now, production processes in the food industry, in particular, have required the use of an extremely wide range of material options. Depending on the fat, flavor or acid concentrations in the food, and the specifications of the CIP/SIP processes and steam sterilization, seals made from EPDM, VMQ or FKM are used.

There are no taste-related surprises: Fluoroprene XP is a universal solution, avoids taste transfer and meets the hygienic requirements of the food industry. So the natural flavor remains unadulterated.

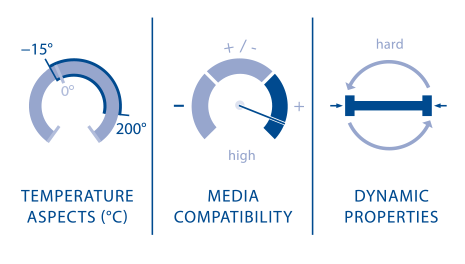

Fluoroprene XP has made these distinctions unnecessary: The material displays high stability in all the critical areas of the food industry and in large portions of the pharmaceutical and chemical industries. It is also impressive for its long service life.

This material hardly absorbs any flavorings at all. This prevents the transfer of flavors from one medium to the next during product changeovers. Fluoroprene XP thus helps to keep flavor transfer to the very minimum. Fluoroprene XP offers excellent seal performance in a broad spectrum of applications at an attractive price level. That makes this material an economical alternative with a high potential as a substitute for other options. As a universal solution, Fluoroprene XP has yet another crucial advantage: The expense of acquiring, certifying and stockpiling seals of different material types is reduced.