Thordon Bearings is the world's leading manufacturer of high

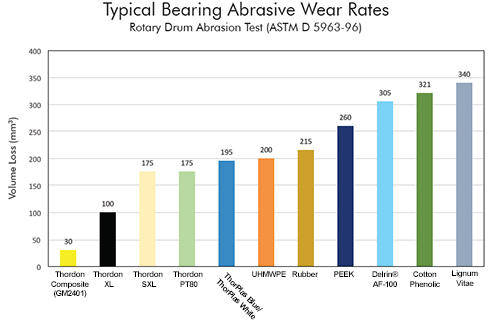

Thordon's abrasive wear rates far outperform all the other "standard" bearing materials, such as phenolic, PEEK, rubber, and many others. The table below shows the bearing volume loss in a Rotary Drum Abrasion Test (ASTM D 5964-96).

But there are many factors that go into choosing the best material for your specific application beyond abrasion resistance, such as coefficient of friction, wet or dry operation, wear characteristics, etc., etc. Below is a quick reference table of which materials do best in different operating parameters.

Gallagher is the northeast and Mid-Atlantic distributor of Thordon Bearings. If you have questions about how oil- and grease-free Thordon bearings can be implemented into your pumps, please do not hesitate to contact us. Thordon materials can be used in almost any other industrial application where long wear life, low friction, high abrasion resistance, or being oil- or grease-free is important.