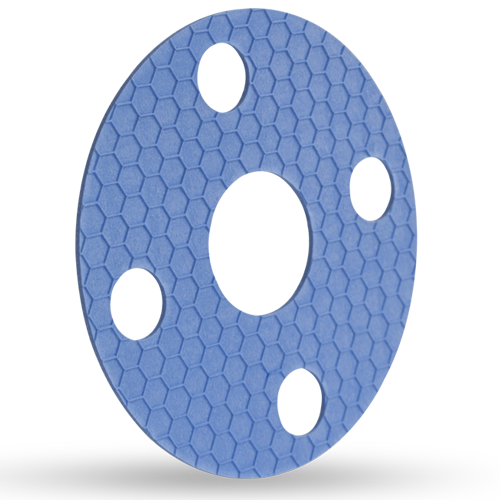

GYLON EPIX™ is a family of gaskets that effectively seals a broader range of applications and is more forgiving during the installation process. It allows the end user to save valuable turn-around time, reduce re-work, and lower costs, helping them to finish ahead of schedule and under budget.

GYLON EPIX™ features a hexagonal surface profile that provides the torque retention and blowout resistance of a thin gasket and the conformability of a thicker gasket. GYLON EPIX™ Style 3504 EPX is a high performance, aluminosilicate microsphere filled PTFE sheet material designed for use in moderate concentrations of acids, and caustics, as well as hydrocarbons, refrigerants, and more.

INDUSTRY

Chemical

CUSTOMER

Phosphate Processor

BACKGROUND

Pump inlet and discharge flanges

CHALLENGES FACED

Customer was using glass filled PTFE. The flange surfaces were being filled with epoxy when maintenance assessed the surface's condition to be undesirable.

OPERATING CONDITIONS

Application 1: Sulfuric Acid 99%

- Temperature: 104°F (40°C)

- Equipment: Pump for sulfuric acid transfer

- Pump Discharge: 8", Alloy 20, Class 150, raised face flanges with B7 bolts

- Pressure: 57 psig (4 kg/cm2)

Application 2: Phosphoric & Sulfuric Acid 99%

- Temperature: 104°F (40°C)

- Pump Discharge: 8", Alloy 20, Class 150, raised face flanges with B7 bolts

- Pressure: 57 psig (4 kg/cm2)

SOLUTION AND BENEFITS

Through close collaboration with the customer, it was determined that the best solution would be the new GYLON EPIX™ 3504 EPX. Installation of 8” ring gaskets was complete without special handling using the plant’s standard practices.