The spectrum of elastomers range from very simple forms, like the natural rubber already in use in the 19th century, to modern, high performance elastomers from the second half of the 20th century. They are continually being improved.

This blog article is the second in a two-part series discussing the many different elastomer materials available today, as discussed in Freudenberg's The World of Freudenberg Sealing Technologies.

The first post discussed Natural Rubber (NR), Nitrile Rubber (NBR), and Hydrogenated Nitrile Rubber (HNBR).

Polyacrylate Rubber (ACM)

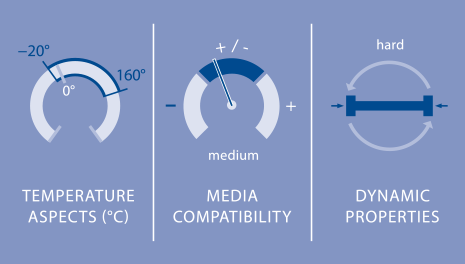

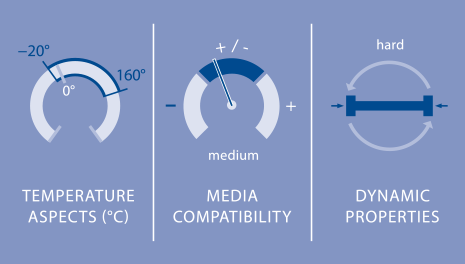

ACM elastomers are made of polar acrylic acids. As polar materials, they display good resistance to high-additive lubricating oils. Due to its saturated¹ main chain, the material exhibits good resistance to ozone, weather and heated air. Petroleum-based oils and fluids (for engines, transmissions and automatic transmissions) cannot harm them. But the material offers only moderate strength and low elasticity while displaying limited cold behavior.

ACM elastomers are made of polar acrylic acids. As polar materials, they display good resistance to high-additive lubricating oils. Due to its saturated¹ main chain, the material exhibits good resistance to ozone, weather and heated air. Petroleum-based oils and fluids (for engines, transmissions and automatic transmissions) cannot harm them. But the material offers only moderate strength and low elasticity while displaying limited cold behavior.

ACM is not stable in hot water, steam, fuels, polar solvents (e.g. acetone, MEK, aromatic hydrocarbons (benzene, xylene, tolulene), chlorinated hydrocarbons, and glycol-based brake fluids, acids, lyes and amines, along with hydraulic fluids (HFA, HFD, HFC, HFD).

ACM is not stable in hot water, steam, fuels, polar solvents (e.g. acetone, MEK, aromatic hydrocarbons (benzene, xylene, tolulene), chlorinated hydrocarbons, and glycol-based brake fluids, acids, lyes and amines, along with hydraulic fluids (HFA, HFD, HFC, HFD).

In high volumes, ACM is an affordable alternative to HNBR and FKM with good high-temperature behavior up to 160 °C. It is above all employed in automotive transmissions – e.g. in Simmerrings, O-rings, housing covers and oil pan seals.

¹ If a polymer no longer has any reactive double bonds, it is described as saturated.

Ethylene Propylene Diene Rubber (EPDM)

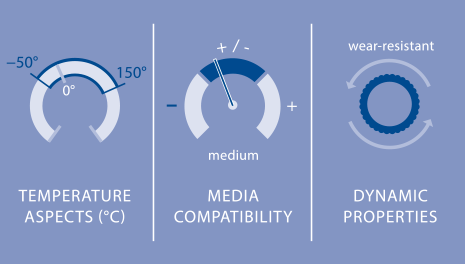

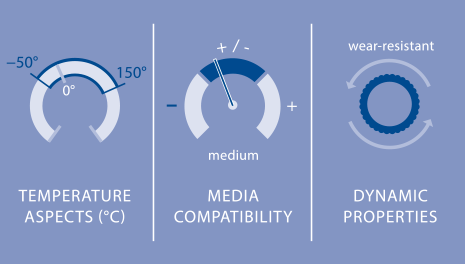

EPDM enjoys high acceptance in the food and pharmaceutical industries. Freudenberg Sealing Technologies has numerous approvals for this material¹. EPDM is indispensable for CIP (clean in place) or SIP (sterilization in place) cleaning processes. However, the fat content of the media may not exceed certain limits. EPDM is a polymerization made of ethylene, propylene and a diene monomer².

EPDM enjoys high acceptance in the food and pharmaceutical industries. Freudenberg Sealing Technologies has numerous approvals for this material¹. EPDM is indispensable for CIP (clean in place) or SIP (sterilization in place) cleaning processes. However, the fat content of the media may not exceed certain limits. EPDM is a polymerization made of ethylene, propylene and a diene monomer².

It displays high media resistance to brake fluids, acids and lyes, the flame-resistant hydraulic fluids HFC and HFD, hot water and steam. But it is not stable in petroleum-based oils and fats or in gasoline and hydrocarbons. In turn, this material is inexpensive and can be used almost universally in the temperature range between −50°C to 150°C – although not with oils.

Sealing profiles constructed of EPDM are primarily found in automobiles – for doors and trunks, windows and headlights. Due to its high hot water stability, EPDM is used in seals and hoses in washing machines and dishwashers, and in nearly all window seals in buildings.

Sealing profiles constructed of EPDM are primarily found in automobiles – for doors and trunks, windows and headlights. Due to its high hot water stability, EPDM is used in seals and hoses in washing machines and dishwashers, and in nearly all window seals in buildings.

¹ For example, FDA 21 CFR 177.2600, 3-A® Sanitary Standards Class II, EU Reg. 1935/2004, USP Ch. 87 and Ch. 88 – Class VI, ADI-free

² Dienes are organic compounds that contain two carbon-carbon double bonds, such as dicyclopentadiene

Silicone Rubber (VMQ, PVMQ, FVMQ)

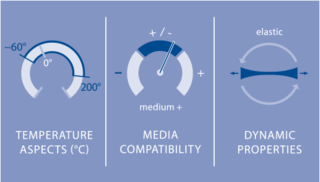

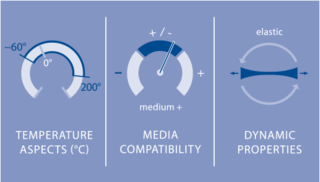

Silicone rubbers belong to the category of synthetic polymers in which silicon atoms are linked together with oxygen atoms. They are stable in hot air and ozone, in water, in animal and plant oils, and fats. But they do not stand up to low molecular weight esters¹ and ethers, acids and alkalis, along with aliphatic (such as gasoline, propane and methane) and aromatic hydrocarbons (such as benzene, xylene and tolulene).

Silicone rubbers belong to the category of synthetic polymers in which silicon atoms are linked together with oxygen atoms. They are stable in hot air and ozone, in water, in animal and plant oils, and fats. But they do not stand up to low molecular weight esters¹ and ethers, acids and alkalis, along with aliphatic (such as gasoline, propane and methane) and aromatic hydrocarbons (such as benzene, xylene and tolulene).

Silicone rubber displays high thermal resistance and good cold flexibility from −60°C to 200°C, but has little tensile strength, elongation or abrasion resistance. VMQ silicone elastomers are used in demanding thermal applications, and, due to their purity, are especially suited for hygienic uses in the food and pharmaceutical industries. Due to its very good physiological characteristics, silicone is a proven sealing material, especially for butterfly valve  seals. Their low breakaway torque ensures reliable switching over their entire lifecycle. Seals made of liquid silicone (LSR) can even adopt the phenomenon of ultrahydrophobicity. Without a coating or a material change, the mold leaves behind a hill and valley structure in the micron range. The friction-reducing seal surface contributes to significantly easier assembly.

seals. Their low breakaway torque ensures reliable switching over their entire lifecycle. Seals made of liquid silicone (LSR) can even adopt the phenomenon of ultrahydrophobicity. Without a coating or a material change, the mold leaves behind a hill and valley structure in the micron range. The friction-reducing seal surface contributes to significantly easier assembly.

¹ Chemical bond that results from an alcohol and an organic (or inorganic) acid subjected to dehydration

Fluoro Rubber (FKM)

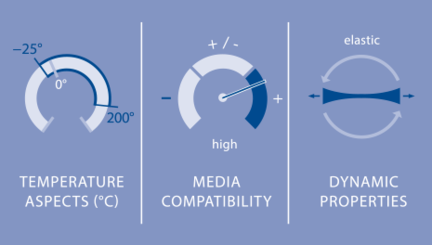

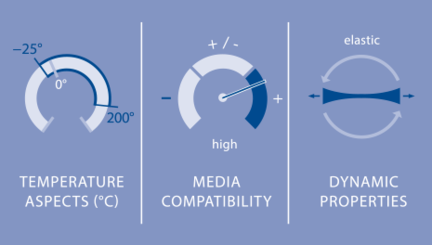

FKM is a copolymer made of highly fluorinated hydrocarbons and developed during the 1950s. FKM displays very good resistance to media, ozone and aging. The material is also stable in fuels as well as petroleum-based oils and greases, along with aliphatic and aromatic hydrocarbons. It is unstable with regard to polar solvents (e.g. acetone, MEK and ethyl acetate), low molecular weight organic acids (formic and acetic acid), glycol-based brake fluid, ammonia gas, amines, alkalis and superheated steam. There are copolymers, terpolymers and tetrapolymers with fluorine content varying between 65 and 71 percent. In this way, FKM can be precisely designed for specific requirements in terms of media resistance and cold flexibility. This is a benefit that, in particular, reliably protects applications in the food and pharmaceutical industries that have aggressive media and process temperatures of above 140°C, which materials such as EPDM or HNBR cannot handle.

FKM is a copolymer made of highly fluorinated hydrocarbons and developed during the 1950s. FKM displays very good resistance to media, ozone and aging. The material is also stable in fuels as well as petroleum-based oils and greases, along with aliphatic and aromatic hydrocarbons. It is unstable with regard to polar solvents (e.g. acetone, MEK and ethyl acetate), low molecular weight organic acids (formic and acetic acid), glycol-based brake fluid, ammonia gas, amines, alkalis and superheated steam. There are copolymers, terpolymers and tetrapolymers with fluorine content varying between 65 and 71 percent. In this way, FKM can be precisely designed for specific requirements in terms of media resistance and cold flexibility. This is a benefit that, in particular, reliably protects applications in the food and pharmaceutical industries that have aggressive media and process temperatures of above 140°C, which materials such as EPDM or HNBR cannot handle.

Fluoro rubber can be used from −25°C to 200°C and is predominantly used for seals in the automotive and commercial vehicle industry and in petroleum production, along with the chemical and aerospace sectors. Special types of FKM are even flexible at −40°C. In general industry, FKM is used wherever there are high rotational speeds and high temperatures, for example, in radial shaft seal rings in pumps and transmissions.

Fluoro rubber can be used from −25°C to 200°C and is predominantly used for seals in the automotive and commercial vehicle industry and in petroleum production, along with the chemical and aerospace sectors. Special types of FKM are even flexible at −40°C. In general industry, FKM is used wherever there are high rotational speeds and high temperatures, for example, in radial shaft seal rings in pumps and transmissions.

Gallagher has been specifying elastomers for a multitude of applications for over half a century. If you have any questions regarding seal elastomers, please feel free to contact us, and our engineering department will follow up with you.

ACM elastomers are made of polar acrylic acids. As polar materials, they display good resistance to high-additive lubricating oils. Due to its saturated¹ main chain, the material exhibits good resistance to ozone, weather and heated air. Petroleum-based oils and fluids (for engines, transmissions and automatic transmissions) cannot harm them. But the material offers only moderate strength and low elasticity while displaying limited cold behavior.

ACM elastomers are made of polar acrylic acids. As polar materials, they display good resistance to high-additive lubricating oils. Due to its saturated¹ main chain, the material exhibits good resistance to ozone, weather and heated air. Petroleum-based oils and fluids (for engines, transmissions and automatic transmissions) cannot harm them. But the material offers only moderate strength and low elasticity while displaying limited cold behavior. ACM is not stable in hot water, steam, fuels, polar solvents (e.g. acetone, MEK, aromatic hydrocarbons (benzene, xylene, tolulene), chlorinated hydrocarbons, and glycol-based brake fluids, acids, lyes and amines, along with hydraulic fluids (HFA, HFD, HFC, HFD).

ACM is not stable in hot water, steam, fuels, polar solvents (e.g. acetone, MEK, aromatic hydrocarbons (benzene, xylene, tolulene), chlorinated hydrocarbons, and glycol-based brake fluids, acids, lyes and amines, along with hydraulic fluids (HFA, HFD, HFC, HFD). EPDM enjoys high acceptance in the food and pharmaceutical industries. Freudenberg Sealing Technologies has numerous approvals for this material¹. EPDM is indispensable for CIP (clean in place) or SIP (sterilization in place) cleaning processes. However, the fat content of the media may not exceed certain limits. EPDM is a polymerization made of ethylene, propylene and a diene monomer².

EPDM enjoys high acceptance in the food and pharmaceutical industries. Freudenberg Sealing Technologies has numerous approvals for this material¹. EPDM is indispensable for CIP (clean in place) or SIP (sterilization in place) cleaning processes. However, the fat content of the media may not exceed certain limits. EPDM is a polymerization made of ethylene, propylene and a diene monomer². Sealing profiles constructed of EPDM are primarily found in automobiles – for doors and trunks, windows and headlights. Due to its high hot water stability, EPDM is used in seals and hoses in washing machines and dishwashers, and in nearly all window seals in buildings.

Sealing profiles constructed of EPDM are primarily found in automobiles – for doors and trunks, windows and headlights. Due to its high hot water stability, EPDM is used in seals and hoses in washing machines and dishwashers, and in nearly all window seals in buildings.

seals. Their low breakaway torque ensures reliable switching over their entire lifecycle. Seals made of liquid silicone (LSR) can even adopt the phenomenon of ultrahydrophobicity. Without a coating or a material change, the mold leaves behind a hill and valley structure in the micron range. The friction-reducing seal surface contributes to significantly easier assembly.

seals. Their low breakaway torque ensures reliable switching over their entire lifecycle. Seals made of liquid silicone (LSR) can even adopt the phenomenon of ultrahydrophobicity. Without a coating or a material change, the mold leaves behind a hill and valley structure in the micron range. The friction-reducing seal surface contributes to significantly easier assembly.

Fluoro rubber can be used from −25°C to 200°C and is predominantly used for seals in the automotive and commercial vehicle industry and in petroleum production, along with the chemical and aerospace sectors. Special types of FKM are even flexible at −40°C. In general industry, FKM is used wherever there are high rotational speeds and high temperatures, for example, in radial shaft seal rings in pumps and transmissions.

Fluoro rubber can be used from −25°C to 200°C and is predominantly used for seals in the automotive and commercial vehicle industry and in petroleum production, along with the chemical and aerospace sectors. Special types of FKM are even flexible at −40°C. In general industry, FKM is used wherever there are high rotational speeds and high temperatures, for example, in radial shaft seal rings in pumps and transmissions.