Below is the second section of the white paper, diving into applications where the measurement is made in analytical laboratories which employ numerous solvents in a wide range of analyses and test equipment.

Laboratory Equipment

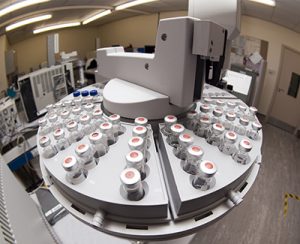

The final set of instrumentation is laboratory test equipment. As opposed to the laboratories in chemical plants, which often perform the same routine analyses on plant process streams, general analytical labs employ numerous solvents in a wide range of analyses and test equipment. As such, the ability of seals to resist a breadth of chemicals without degradation or leaching contaminants into a sample is of great importance. Although instrument seals are easily replaced in a laboratory environment, this operation still takes a technician time. It is always easier if the system can be flushed with a cleaning solvent and then be ready to run the next sample versus having to change out an elastomer seal due to incompatibility with a solvent.

Some examples of this type of equipment include gas chromatographs, flame ionization detectors, and inductively coupled mass spectrometers. In this equipment, contamination of samples, due to elastomer seals, must be avoided. Because of the solvents and/or high temperatures in use, correct elastomer selection is important to avoid seal deterioration or contaminant leaching that could interfere with test results. Depending on the chemicals and application temperatures, high performance elastomer seals can again provide the best option for these services.

Chromatography

Flame Ionization Detectors

Flame ionization detectors are often used with gas chromatographs and provide additional information, such as carbon content of the test sample. Flame temperatures in these detectors are typically more than 150°C. As such, high temperature and low outgassing seals meet the requirements for this service. A number of FKM and FFKM products that are used in the semiconductor industry may provide the excellent high temperature performance and low outgassing that is needed for this type of service. Selection of the optimum product for the application will maximize equipment service life and performance.

High Performance Liquid Chromatography

The comments above can be generalized for any type of lab instrumentation that requires the use of solvents and/or elevated temperatures. In these applications FKM and FFKM seals allow equipment to be used in the broadest range of applications without the need for frequent change out of elastomer components. This approach can also reduce inventory requirements since spare parts don’t require multiple elastomer seals for specific applications.