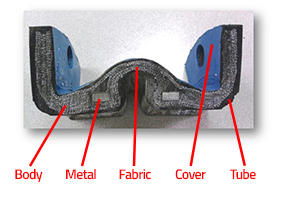

From the outside, an elastomeric expansion joint looks to simply be made out of molded rubber. Part of the reason expansion joints are used in such a wide variety of applications is that the interior construction of a joint can be custom-designed to handle your specific application - materials of construction will depend on size, temperature, application, media, pressure (S.T.A.M.P.).

Layers of Construction

Tube

- Synthetic or natural rubber forms seamless, leak-proof lining

- Extends fully through bore to outer flange edge

- Common materials include chlorobutyl, neoprene, natural rubber, EPDM, Viton* and Hypalon*

Body or Carcass

- When wrapped or plied, reinforcements provide support and flexibility between tube and cover

- Fabric reinforcement: polyester or other suitable fabrics impregnated with specified elastomers

- Metal reinforcement: bonded rectangular steel rings [exclusive to Garlock], or continuous strands of wire and round steel body rings

- Metal reinforcement rings provide longer service life, extra safety protection, and extra rigidity, allowing higher pressure ratings

Cover

- Homogeneous layer of synthetic or natural rubber

- Chlorobutyl is standard; other elastomers available to meet your specific application

- Rubber or other weather-resistant coating protects carcass from corrosion or damage

Metal Flow Liners

- Must be used in all applications; provides metal surface to distribute bolting pressure equally, preventing flange damage during bolt tightening

- Install against external flange surface

- Standard material: mild steel with corrosion-resistant coating; galvanized or stainless steel also available

- Extends service life by providing protection from abrasive materials or solids, especially in high velocity applications

- Flanged at one end, installed at the head of the flow, tapered to a 5° angle, allows lateral deflection

- Liner flange thickness: 10 gauge | Liner body thickness: 12 gauge

- Available in 304/316 stainless steel; also: titanium, Hastelloy C

- Special metal liner configurations also available for reducing or multiple arch design.

Control Units

- Recommended on most applications to prevent damage due to excessive pipe movements

- Consists of two or more tie rods connected between pipe flanges

- Triangular end plates (gussets) have two holes for bolting securely to flange, and one hole to accommodate the connecting tie rod

- Spherical washers are incorporated to accommodate moderate piping alignments, but also assists with angular, torsional and lateral movements

- Each rod incorporates double nuts on each end to keep the expansion joint from over-elongating

- When excessive axial compression is a concern, compression nuts can be incorporated to restrict movements as needed and to protect the expansion joint from damage

- NOT designed to replace pipeline anchoring

Accessories

Fire Resistant Covers

- Recommended on applications where flammable liquids are being used or in fire water systems.

- Consists of several layers of fiberglass fabric with a surface cover of silver-colored high temperature resistant silicone aluminum-glass fabric

- Tested to ISO 1554 at 800˚C for 30 mins for fire resistance

- Split design which allows for easy installation or inspection

- Cover is oil resistant and provides added protection against weathering and aging of the expansion joints.

Metal Retaining Rings

- Must be used in all applications; provides metal surface to distribute bolting pressure equally, preventing flange damage during bolt tightening

- Install against external flange surface

- Standard material: mild steel with corrosion-resistant coating; galvanized or stainless steel also available