Article re-posted with permission from Parker Hannifin Sealing & Shielding Team.

Original content can be found on Parker’s Blog.

Contact GFS about battery sealing solutions >>

Sealing can often be a frustrating challenge when dealing with batteries and battery storage solutions. Determining what materials are compatible with certain chemistries or developing a profile that provides optimal sealing under available compression can be a time-consuming task for those outside the sealing industry. A trial and error approach can have a significant overall cost impact through multiple prototype iterations, prolonged testing, and ultimately, delaying product commercialization.

Specialized support

With Gallagher Fluid Seals and Parker Sealing's design and material engineers, we can provide support to your team in the critical, early stages of product development. With hundreds of engineered elastomeric materials to choose from, Parker and GFS can identify and recommend a compound that works with your specific electrolytes or other fluids. With the exceptionally long lifetime requirements of flow batteries, Parker's homogeneous rubber provides the elasticity needed to handle the many charge-discharge cycles the battery will see in its life.

Finite Element Analysis (FEA)

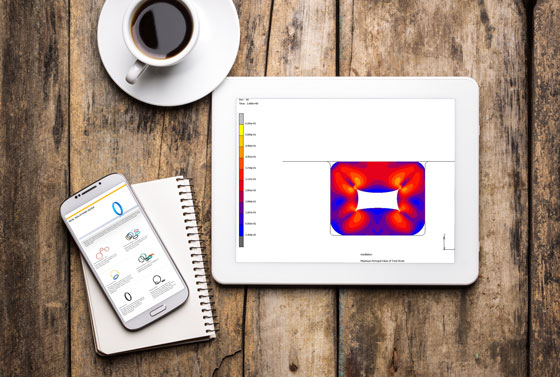

Parker and Gallagher Seas engineers can significantly reduce design time by utilizing finite element analysis early in the process. FEA is a sophisticated computer modeling program that demonstrates a visual simulation of how materials for a proposed seal design might perform in the application. Material performance over a range of conditions is tested to see if the product will perform as expected. FEA can be repeated as many times as needed to fine-tune the design and make the final product as robust, functional, and reliable as possible.

This process can be performed before prototyping, mold design or production is undertaken, greatly reducing the possibility of errors or redesign issues occurring later.

Launch speed is critical

With continuous advancements materializing in the energy storage market, we fully understand the urgency of moving a product from development to commercialization. Parker and Gallagher Seals can provide your team with resources to improve both the quality and speed of seal design in the critical prototyping stage, reducing overall cost.

After commercialization, Parker’s O-Ring & Engineered Seals Division can support your high volume production utilizing one of our 14 manufacturing locations dedicated to molding and extruding elastomeric products. To ensure the highest levels of material quality, state-of-the-art laboratories and testing equipment are housed in our two North American technology centers.

For more information, visit Parker O-Ring & Engineered Seals Division online.

This article was contributed by Wesley Burcham, Market Manager, Parker O-Ring & Engineered Seals Division.

Source: http://blog.parker.com/engineered-materials-and-sealing-solutions-for-flow-batteries