Flue Duct Expansion Joints

Used to manage air and gas handling systems, flue duct expansion joints are most widely utilized in the Power Generation, Industrial & Institutional industries:

-

- Simple Cycle

- Combined Cycle

- Co-generation

- Coal Fired

- Industrial Operations

- Steel Mills

- Paper Mills

- Cement Plants

- Institutional Sites

- Hospitals

- Schools

- University Campuses

Joint Selection

When specifying a flue duct expansion joint, consider the following parameters:

- Temperature

- Movement

- Media (wet and or/dry)

- Chemical compatibility of gas and particulate

- Environmental exposure

- Level of contamination or particulate volume (fly ash)

- External environment

- Safety and/or any regulatory requirements

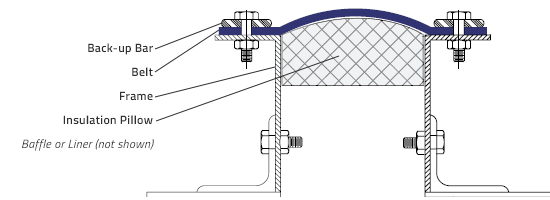

Flue Duct Expansion Joint Components

Similar to the elastomeric and metal joints already discussed, flue duct expansion joints are installed to relieve stress on a piping or ducting system. Flue duct expansion joints are custom designed and made-to-order to manage thermal expansion, noise reduction, vibration, wind and seismic loads, movement absorption, and system stress relief conditions unique to each customer’s site.

With a wide range of materials, frames, baffles, insulation, and attachment styles available, these joints can be built to meet any thermal, chemical, or environmental demands of diverse systems, equipment, and processes.

Construction of the expansion joint includes non-metallic belts made from EPDM, FKM, CR, Silicone, and PTFE materials. Whether utilized as a shell, barrier or buffer layer, elastomers may be reinforced and bonded with composite cloths including fiberglass, ceramics, aramid fiber, and stainless steel to suit service conditions and performance requirements.

Frames, Baffles, and Liners

Metal frames, baffles, and flow liners are precision matched to fit the design envelope of the customer’s application. Baffles and liners are specified to manage flow and lessen the accumulation an trapping of particulate. These are constructed of carbon steel or higher nickel steels available for today’s demanding environments.

Insulation Pillows

Normally required when operating temperatures are above 750°F. Materials of construction are selected based upon performance requirements and the specific operating conditions of the application.

Chemical and Exposure Compatibility of Common Belt Materials

If you have questions about flue duct expansion joints, or expansion joints in general, and how they can be better utilized in your processes, please do not hesitate to contact us. Gallagher Fluid Seals represents numerous expansion joint manufacturers such as Garlock, Parker, Hose Master, and General Rubber, allowing us to find the best expansion joint for your application.