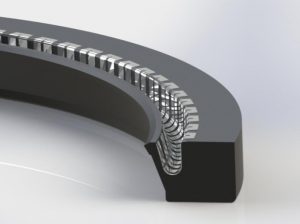

KLOZURE® Oil seals from Garlock® KLOZURE® are available in a wide variety of configurations to meet the requirements of major industries. MILL-RIGHT® materials are used on all elastomeric seals for superior bearing protection. KLOZURE® Oil Seals are available in more than 50 different styles in sizes from ¼" to over 90", solid or split, metal-cased or all-rubber. KLOZURE® Oil Seals have had a strong brand presence in the U.S. since the 1920’s. Today they are also manufactured and branded in China and Germany. Technology has advanced over the years, and the oil seals are now available in MILL-RIGHT® elastomers which provide longer service life than their predecessors.

KLOZURE® Oil seals from Garlock® KLOZURE® are available in a wide variety of configurations to meet the requirements of major industries. MILL-RIGHT® materials are used on all elastomeric seals for superior bearing protection. KLOZURE® Oil Seals are available in more than 50 different styles in sizes from ¼" to over 90", solid or split, metal-cased or all-rubber. KLOZURE® Oil Seals have had a strong brand presence in the U.S. since the 1920’s. Today they are also manufactured and branded in China and Germany. Technology has advanced over the years, and the oil seals are now available in MILL-RIGHT® elastomers which provide longer service life than their predecessors.

There are many different styles and variations available from Garlock® KLOZURE®, but below are some of the more popular oil seals.

Model 23 - General Purpose Split Seal

Features & Benefits

• Cover plate required

• Over 300K sizes available

Specifications

Minimum Shaft Diameter: 3.000in. (76.2mm)

Maximum Shaft Diameter: 120.000in. (3048.0mm)

Misalignment and Runout:

.010" @ 1,000 fpm (.25mm @ 5.1 m/s)

.005" @ 2,000 fpm (.13mm @ 10.2 m/s)

Spring Configuration: Molded-in SS Finger Spring

Model 53 - General Purpose Assembled Seal

Features & Benefits

• Heavy-duty metal outer case

• Single and dual lip configurations available

Specifications

Minimum Shaft Diameter: 3.000in. (76.2mm)

Maximum Shaft Diameter: 60.000in. (2286.0mm)

Misalignment and Runout: Configuration dependant

Pressure: To 7psi (0.4bar)

Spring Configuration: Molded-in SS Finger Spring

Model 59 - Heavy Duty Seal

Features & Benefits

• Heavy-duty metal outer case

• Reverse bevel lip design prevents lip rollover

• Aggressive shaft to bore misalignment capability

Specifications

Minimum Shaft Diameter: 6.000in. (152.4mm)

Maximum Shaft Diameter: 70.000in. (1778.0mm)

Misalignment and Runout:

.093" @ 2,500 fpm (2.36mm @ 12.7 m/s)

.047" @ 5,000 fpm (1.19mm @ 25.4 m/s)

Pressure: To 7psi (0.4bar)

Spring Configuration: Molded-in SS Finger Spring

Material Options: Mill-Right N, Mill-Right ES, Mill-Right V

Contact our Engineering Department for assistance in selecting the right oil seal for your application.