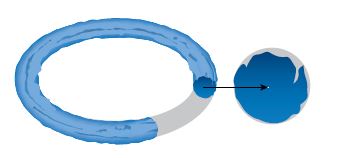

Watch the video below from Parker's O-Ring eHandbook, showing how extrusion & nibbling can happen.

Factors contributing to extrusion or nibbling:

1. Excessive clearances between the piston and bore.

2. High pressure (in excess of system design or high pressure excursions).

3. Material too soft.

4. Degradation (swelling, softening, shrinking, cracking, etc.) of material by system fluid.

5. Irregular clearance gaps caused by eccentricity.

6. Increase in clearance gaps due to excessive system pressure.

7. Improper machining of O-ring gland (sharp edges).

8. Improper size (too large) O-ring installed causing excessive filling of groove.

Preventing and correcting the causes of extrusion or nibbling:

1. Decrease clearance by reducing machining tolerances.

2. Use back-up with the O-ring, or replace with a D-ring or Double Chamfered Precision Cut seal.

3. Check material compatibility with system fluid.

4. Increase rigidity of metal components.

5. Replace current O-ring with one which is harder.

6. Break sharp edges of gland to a minimum radius 0.005 inches.

7. Insure installation of proper size O-rings.