GORE UPG Ring and Full Face Gaskets

GORE® Universal Pipe Gaskets (Style 800) provide a reliable seal for steel, glass-lined steel and fiber reinforced plastic (FRP) flanges, in the full spectrum of strong acid, alkali, and solvent process media, including the most challenging thermal cycling and elevated temperature applications.

This single gasket solution can reduce the process safety and production downtime risks caused by the use of an incorrect gasket material. The highly conformable 100% ePTFE also reliably seals irregular surfaces.

MATERIAL

100% ePTFE (expanded polytetrafluoroethlyene), with multi-directional strength

OPERATING RANGE

The maximum applicable pressure and temperature depend mainly on the equipment and installation.

Typical Use: -76ºF to 446ºF (-60ºC to 230ºC); industrial full vacuum1 to 40bar (580psi)

Maximum Use: -452ºF to 600ºF (-269ºC to 315ºC); full vacuum to 210bar (3,000psi)

For applications outside the typical use range, Gore recommends an application specific engineering design calculation and extra care during installation. Also, consider retorquing after a thermal cycle when the equipment has returned to an ambient temperature condition. Please contact Gore if further guidance is required.

CHEMICAL RESISTANCE

Chemical resistance to all media pH 0-14, except molten alkali metals and elemental fluorine.

SHELF LIFE

ePTFE is not subject to aging and can be store indefinitely.

PRODUCT SIZES

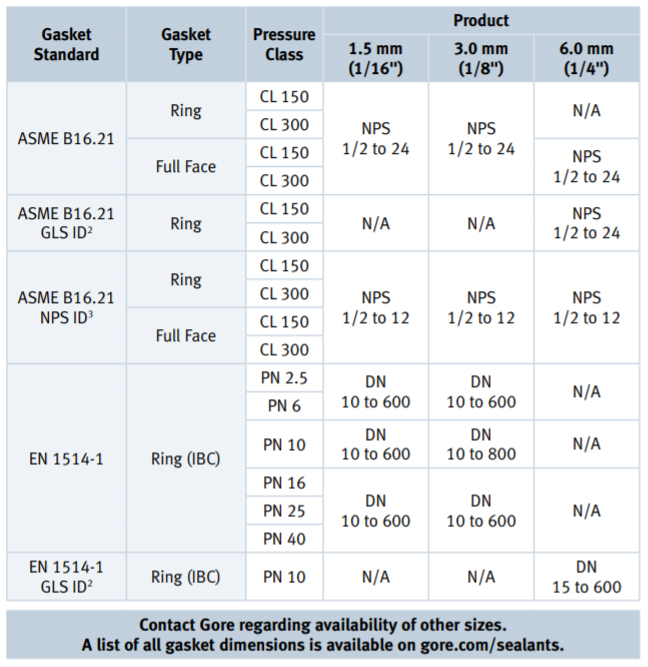

The GORE® Universal Pipe Gaskets are available as ring or full face gaskets, manufactured to ASME and EN standards.

What is ePTFE and GORE® UPG?

For more information on GORE® Universal Pipe Gaskets, or any other gasketing requirements, contact the Gallagher Engineering Department.