Poppet Seals for Demand Flow Regulators

Avoid Leakage and Support a More Accurate System

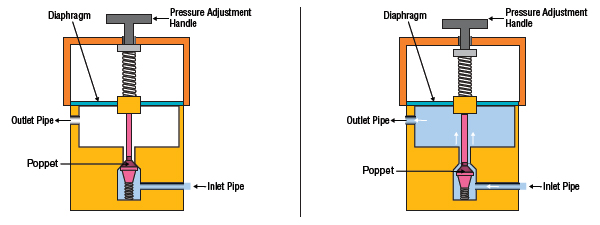

Parker Composite Sealing Systems Division designs different poppets to help control leakage in flow control applications. Our poppet is used to help keep the demand flow regulators in the “closed” position. And when the user “demands” gas flow, a diaphragm pushes down on the seat stem of the Poppet to help monitor the flow of gas.

Features & Benefits

- Ability to hold tight tolerances

- No lubricant needed

- Endures high pressure applications

- Variety of material combinations to seal specific fluids

- Elastomer is bonded to the poppets

- Available in various sizes to service a broad range of applications

- CBI Traceability

- Individual packaging available

Typical Applications / Users

- Gas Regulators

- Compressor Manufacturers

- Generator Manufacturers

- Marine Industry

- Nuclear Industry

- MRO Facilities

- Aerospace

Gallagher Fluid Seals is a Top-10 Distributor of Parker sealing products. With a long history of specifying Parker products, we can determine the best product for any application you're having an issue with. Contact our Engineering Department if you ever need assistance designing a sealing solution.