Article re-posted with permission from Parker Hannifin Sealing & Shielding Team.

Original content can be found on Parker’s Blog.

A Guide to Proper Storage and Cleaning of Elastomer Seals

Elastomer seals from Parker Prädifa meet the most exacting demands in a wide range of applications. Aside from the appropriate seal designs, the material properties of the seal compounds are crucial to ensuring that seals deliver the desired performance.

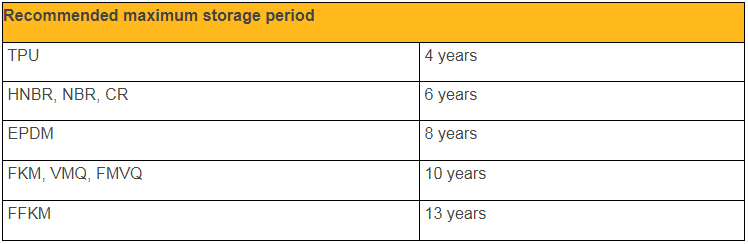

A key criterion for the storage period of elastomers is the time at which the product was vulcanized. Parker indicates the date of manufacture on the packaging bags: “1Qxx” stands for parts produced in the first quarter of the year 20xx. The recommended maximum storage period depends on the type of elastomer.

Factors that influence the storage of elastomer seals

The properties profile of an elastomer seal typically remains constant for years if the seal is properly stored. Improper storage conditions, on the other hand, can drastically reduce a seal’s potential shelf life due to a large number of influencing factors (see Figure). Ultimately, the seal will no longer be fit for use due to hardening, softening, permanent deformation, cracks, surface damage, etc.

To avoid this, Parker Prädifa, based on the DIN 7716 and ISO 2230 standards, recommends that the following information is observed for storage, storage periods and cleaning of elastomer seals:

Storage

Temperature

![]() The preferred storage temperature for elastomer products is +15 °C and should not exceed +25 °C. Accordingly, sources of heat such as radiators, boilers (minimum distance: 1 meter) or direct sunlight should be avoided. Temperatures should not drop below a maximum of -10 °C. As in this case, a stiffening of elastomer products occurs the seals should be handled with special care to prevent deformation. Chloroprene materials should not be stored below -12 °C.

The preferred storage temperature for elastomer products is +15 °C and should not exceed +25 °C. Accordingly, sources of heat such as radiators, boilers (minimum distance: 1 meter) or direct sunlight should be avoided. Temperatures should not drop below a maximum of -10 °C. As in this case, a stiffening of elastomer products occurs the seals should be handled with special care to prevent deformation. Chloroprene materials should not be stored below -12 °C.

Humidity

![]() It is important to ensure that the relative humidity in storage facilities is below 65%. Storage in humid rooms and condensation must be avoided. Neither should elastomer seals be stored in extremely dry conditions.

It is important to ensure that the relative humidity in storage facilities is below 65%. Storage in humid rooms and condensation must be avoided. Neither should elastomer seals be stored in extremely dry conditions.

Light / Radiation

![]() Elastomer seals must be protected against sources of light with a high UV content as they might be able to damage the products. Examples of light sources with a high UV content include intense artificial light or direct sunlight. Light-induced (photo) damage can be avoided by adequate application of UV filters to the window panes in the storage room. All types of radiation such as gamma or radioactive radiation must be avoided.

Elastomer seals must be protected against sources of light with a high UV content as they might be able to damage the products. Examples of light sources with a high UV content include intense artificial light or direct sunlight. Light-induced (photo) damage can be avoided by adequate application of UV filters to the window panes in the storage room. All types of radiation such as gamma or radioactive radiation must be avoided.

Oxygen / Ozone

![]() Generally, elastomer seals should be protected against circulating air by suitable packaging such as airtight containers. This is particularly important for very small seals with a large surface-to-volume ratio. Mercury vapor lamps, fluorescent light sources, electric motors – generally any device that is capable of producing ozone through sparks, electrical discharges or high-voltage fields – must urgently be avoided. Ozone is harmful to many elastomers so that storage rooms must be ozone-free. This also applies to organic gases as well as combustion gases as they are capable of producing ozone via a photochemical process.

Generally, elastomer seals should be protected against circulating air by suitable packaging such as airtight containers. This is particularly important for very small seals with a large surface-to-volume ratio. Mercury vapor lamps, fluorescent light sources, electric motors – generally any device that is capable of producing ozone through sparks, electrical discharges or high-voltage fields – must urgently be avoided. Ozone is harmful to many elastomers so that storage rooms must be ozone-free. This also applies to organic gases as well as combustion gases as they are capable of producing ozone via a photochemical process.

Solvents / Greases

![]() Greases, oils and solvents may cause damage to elastomer seals. Therefore, it should be ensured that the seals cannot come into contact with these media in storage (unless packaged this way by the manufacturer).

Greases, oils and solvents may cause damage to elastomer seals. Therefore, it should be ensured that the seals cannot come into contact with these media in storage (unless packaged this way by the manufacturer).

Deformation

![]() Elastomer seals which are exposed to tensile or compressive strain, or other types of deformation, may be damaged. Cracking may occur. Therefore, the seals must be stored without being exposed to strain and deformation.

Elastomer seals which are exposed to tensile or compressive strain, or other types of deformation, may be damaged. Cracking may occur. Therefore, the seals must be stored without being exposed to strain and deformation.

Miscellaneous

In addition to these recommendations, there are a few other aspects to be observed when storing elastomer seals:

- Elastomer products should not come into contact with metals such as iron, copper and manganese, as this may result in damage. The same applies to respective alloys such as brass and non-metals.

- Contact with materials containing plasticizers, such as PVC, must be avoided.

- Elastomer seals of various types (material, color,…) should be stored separately.

Checking

Generally, elastomer products should be checked to ensure their proper condition prior to installation. Negative changes due to improper storage can usually be detected by visual inspection. The main characteristics discernible in a visual inspection are:

- dirt deposits

- cracks

- hardening

- softening

- stickiness

- discoloration

Cleaning

Elastomer seals should be cleaned swiftly using a clean cloth and lukewarm water. Exceptions are fabric-reinforced elastomer seals. In this case, contact with water must be avoided. Gasoline, benzene, turpentine and similar substances are not suitable for use as cleaning fluids.

Elastomer products must not come into contact with sharp-edged or pointed objects such as steel brushes, sanding paper, etc. Drying near radiators is not recommended.

Additional information:

Brochure: Storage and Cleaning of Elastomer Seals

www.parker.com/praedifa

This article was contributed by Dr. Heinz -Christian Rost, Technology & Innovation Manager, Prädifa Technology Division

Source: http://blog.parker.com/a-guide-to-proper-storage-and-cleaning-of-elastomer-seals