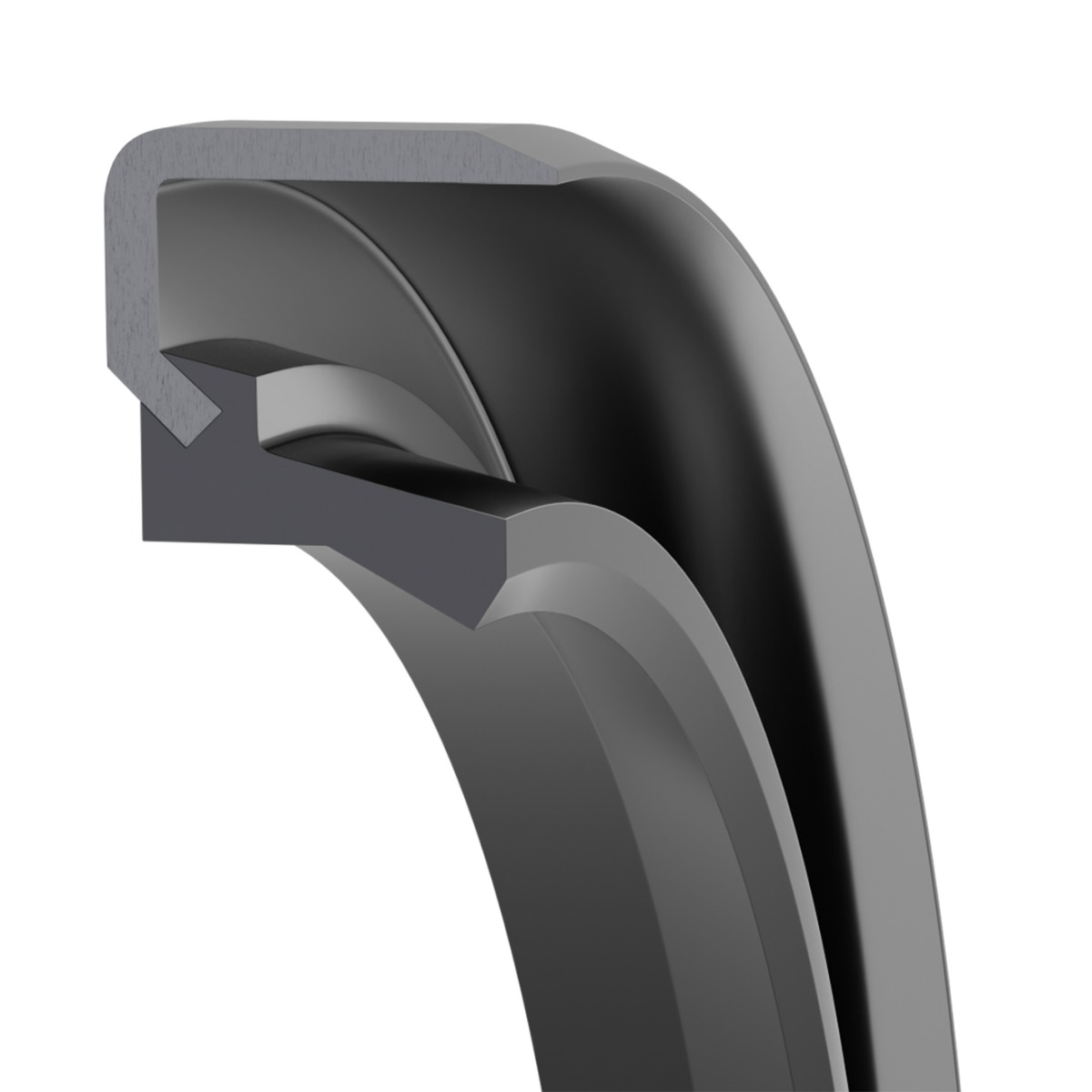

PTFE Radial Lip Seal Design

Before selecting a seal type and the filled PTFE compound to be used in a proposal, it’s important to have a thorough understanding of operating conditions and how they affect the seal performance.

Those factors include:

Temperature

This is perhaps the most crucial thing to consider in PTFE radial lip seal design. Due to PTFE’s high thermal expansion rate, the pronounced change in flexural modulus at various temperatures and the compressive “creep” characteristics, a controlled contact pattern and desirable radial loading on the shaft surface are difficult to control. For a satisfactory seal, the design and material should be directed to the mean functional temperature range.

Shaft speed

On its own, shaft speed has little effect on PTFE lip seals, unless speeds reach a point where severe temperature and wear are generated by the sealing element. But speed is a critical factor in seal design when the application is one with a high degree of shaft run-out, limited lubrication, or when a positive fluid pressure is present and the limiting PV range of the material is approached.

Fluid type and fluid level

PTFE is compatible with most chemicals and lubricants, but it’s important to be careful when selecting filler and seal types for fluids that have no lubricant value. Most lip seals are involved with the sealing of lubricating oils, so type of lubricant generally gets little attention.

Experience with some extreme pressure gear lubricants has shown a definite form of reversion and high wear rate when the RP fluid was exposed to temperatures beyond the recommended limit. Fluid level and/or amount of fluid in the adjacent seal area is a determining factor on usage of a spring or other means to increase radial load.

Dynamic shaft run-out

Shaft run-out is an operational condition that heavily influences the PTFE element design and method of processing the material. To offset the high flexural modulus and allow the equipment to follow the shaft movement, special design considerations and processing techniques are used to obtain the most flexible element possible.

Shaft material and finish

These requirements are the same as the ones applied to elastomer seals. PTFE has a tendency to leave a film onto adjacent shaft surfaces, so a finish of 16 Max rms is recommended for sealing lubricants.

Applications in which water and chemicals are being sealed need a smoother surface finish of 8-12 rms, because normally no transfer to PTFE is obtained.

Steel and cast iron are the best shaft materials, and stainless steel is a better choice than chrome-plated material. It is important that all finishes are produced by plunge grinding or another process that will not produce a helical lead to the shaft surface. Helical leads on shaft surfaces have a greater influence on PTFE than elastomers due to the frictional hardness characteristics of PTFE resins.

Contamination

Contamination is less critical to PTFE resins than it is with elastomers. Elastomers act like a grinding wheel when abrasive particles become embedded. PTFE allows particles to penetrate but then transfers a film over them, minimizing the abrasive action. PTFE radial lip seals have been used without an excluder lip where contamination is light, but an excluder is recommended where heavy contamination is present.

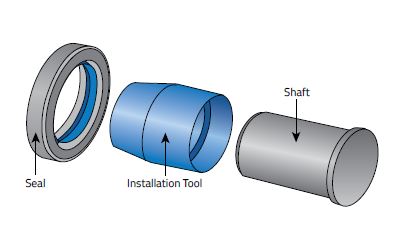

Installation

Installation of a PTFE radial lip seal needs the attention of both the engineer and the end user. Because PTFE is still and lacks the elastic properties of elastomers, damage from sharp edges and burrs on the shaft must be avoided.

In most cases, installation problems can be surmounted with proper seal design selection. If the application requires an element design with heavy interference, and installation onto the shaft is against the PTFE element, an installation tool should be considered.

Installation tools properly align seals to shafts, and protect seals from damage caused by splines, keyways or shafts without a lead-in chamfer. They are typically made of materials such as nylon or PVC.

To learn more about these seals, be sure to download Gallagher’s PTFE rotary lip seal guide.