Today we’ll offer up a short glossary of some of the terms used when discussing these seals. We'll also break down some of the factors affecting PTFE rotary lip seal design.

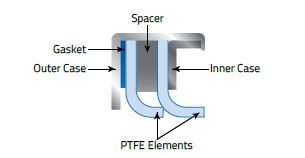

Outer Case

- Houses all components of seal

- Press-fit into bore to prevent seal rotation

Inner Case

- Compress internal components

- Locates bend point of element

Gasket

- Helps prevent internal leakage

- Takes up tolerances in assembly

Spacer

- Locates bend point of element

- Spaces multiple elements apart for ideal sealing

PTFE element(s)

- Mechanically formed to a diameter smaller than the shaft

- Takes advantage of hoop stress of PTFE

Factors Affecting PTFE Rotary Lip Seal Design

Cross-Section and Series: 100

- Style Description -- 1 PTFE Element

- Pressure Range -- 60 psi (0.414 MPa)

- Temperature Range -- -65º to 500ºF (-54º to 260ºC)

- Description/Application -- Rotary shaft seal designed for general purpose where application requires low friction, high pressure, and may contact harsh chemicals. Good for low pressure sealing as well.

Cross-Section and Series: 200

- Style Description -- 2 PTFE elements spaced apart

- Pressure Range -- 250 psi (1.73 MPa)

- Temperature Range -- -65º to 500ºF (-54º to 260ºC)

- Description/Application -- Designed with two elements spaced apart for enhanced sealing in one layout. Excellent for applications where sealing media can be a safety concern. Good for low pressure sealing as well.

Cross-Section and Series: 300

- Style Description -- 1 PTFE element, 1 "wiper" element (opposite direction)

- Pressure Range -- 40 psi (0.276 MPa)

- Temperature Range -- -65º to 500ºF (-54º to 260ºC)

- Description/Application -- Designed for applications requiring sealing high pressure and/or caustic chemicals but also requires keeping dirt, water, or debris away from active sealing surface. Good for low pressure sealing as well.

Cross-Section and Series: 400

- Style Description -- 2 PTFE elements spaced apart, 1 "wiper" element (opposite direction)

- Pressure Range -- 150 psi (1.04 MPa)

- Temperature Range -- -65º to 500ºF (-54º to 260ºC)

- Description/Application -- Combination of the dual design for enhanced sealing with the third element in the opposite direction to keep dirt and debris out. Good for low pressure sealing as well.

Cross Section and Series: 500

- Style Description -- 2 PTFE elements (opposite direction)

- Pressure Range -- 60 psi (0.414 MPa)

- Temperature Range -- -65º to 500ºF (-54º to 260ºC)

- Description/Application -- Designed for bidirectional shafts. Uses two sealing elements facing opposite directions for active sealing on both sides of the seal. Good for low pressure sealing as well.

Cross Section and Series: 600

- Style Description -- 2 PTFE elements (same direction)

- Pressure Range -- 90 psi (0.621 MPa)

- Temperature Range -- -65º to 500ºF (-54º to 260ºC)

- Description/Application -- Another variation of the dual element design. Elements are stacked together which allows sealing at higher pressures and high speeds in abrasive media. Excellent for low pressure sealing as well.

To read more about PTFE rotary lip seals, be sure to download our rotary seals guide.