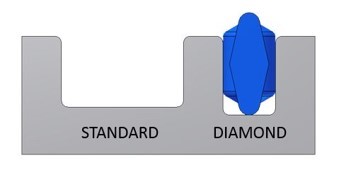

Narrow cross section

With a tall and narrow diamond-like cross section, the diamond seal groove is 60% narrower than traditional grooves for comparable seal heights. The narrow cross section of the seal allows it to be used in tight corners and around small holes. The groove width savings allows housing to become thinner, reducing the weight assemblies and is less expensive to machine when compared to standard grooves.

The Diamond Seal has two types of beads located around the profile of the seal. The stabilizer bead prevents the seal from tipping into the groove. The retention bead provides the interference with the groove wall providing exceptional retention.

Aerospace Applications

Diamond Seals are ideal for the following military and commercial aircraft applications:

- Actuator

- Cockpit control panels

- Electrical control bowes

- Fuel management units

- Fuel pumps

- Guidance modules

- Hatch cover seals

- Housing seals

- Hydraulic motors

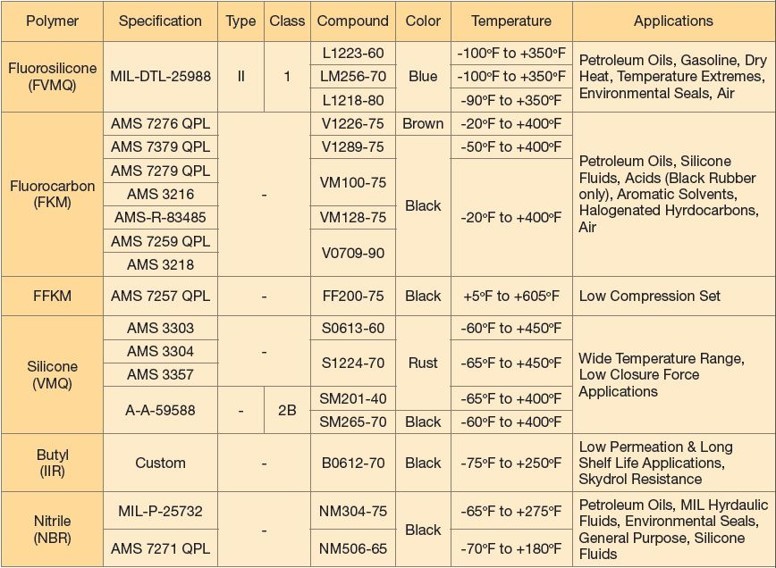

Standard Aerospace Materials

Parker Engineered Seals Division has obtained Qualified Product Listing (QPL) for many standard aerospace compounds in several material families. These compounds can be found in the table below.

Parker is not limited to the use of these materials. Diamond Seals can be molded in almost all of the compounds available in Parker's material library. Parker Diamond Seals material can be tailored to target the right balance of seal load, compliance, chemical resistance, and temperature range.

Parker Diamond Seals are a cost effective sealing solution providing easy assembly, and excellent retention for the most demanding applications.