Parker’s combination of advanced seal design technology and material expertise has produced a reliable zero-leak rod seal package for hydraulic cylinders for greater equipment output which:

- Extends useful cylinder life

- Maximizes equipment uptime

- Extends maintenance intervals

Integral to the design of the zero leak seal package are the characteristics of Parker’s Resilon™ polyurethane material – designed for extended temperature range, wear resistance, compression set resistance, and overall toughness.

Product Features

- Zero-leak rod seal package

- High temperature operating range of -65°F to +275°F

- Up to 5,000 PSI operation

- Seal profiles with knife trimmed sealing lips for zero leak contact points

- Patented Resilon™ polyurethane with excellent wear and rebound characteristics

- Available in water resistant formulation

Advanced Design Technology

Parker rod seal packages are specifically engineered combinations of primary rod seal, buffer seal, and wiper and wear ring profiles. Each profile has features complementary to the package as a whole, collectively producing highly-effective sealing. It is also imperative to understand that the material characteristics of Resilon™ 4300 polyurethane is as integral an aspect of the overall engineered design of the sealing package as each individual profile’s engineered geometry.

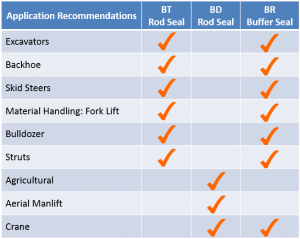

Primary Rod Seals

The BT Profile rod seal is an unloaded u-cup with a secondary stabilizer lip and knife trimmed sealing edge. The angle of the BT lip has been optimized for maintaining a contact force to seal on the rod and maximizing seal life.

Applications: The BT profile is used in high pressure applications where high wear resistance is important.

The BD Profile rod seal is a loaded u-cup with a secondary stabilizer lip and knife trimmed sealing edge. The energized lip maintains continuous high contact force against the sealing surface – making it a great choice for optimum low temperature and / or low pressure.

Applications: The BD profile is designed for maximum sealability in low pressure systems where the rod will not be traveling long distances at high speeds.

Buffer Seal

Parker’s BR Profile is a buffer seal that fits in front of the primary rod seal. Slotted pedestals and a flexible static side lip allow a check-valve type pressure relief to prevent a pressure trap. The Nylatron back-up ring is there to prevent extrusion.

Applications: The BR removes the adverse effects of pressure spikes on the primary rod seal, thus improving the systems sealing capability.

Wiper

Parker’s AH Profile wiper is the ultimate metal-clad excluder featuring press-fit installation to prevent O.D contamination. An aggressive wiping lip, facing the environment, ensures the utmost performance in contaminant exclusion along the rod. The additional sealing lip works in conjunction with Parker rod seals to provide redundant sealing for leakage reduction.

Applications: Heavy duty hydraulic applications.

Proven Performance

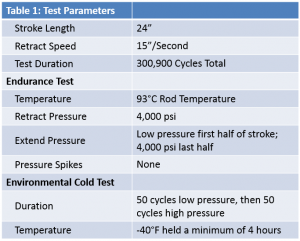

The performance of Parker’s rod sealing system can be well displayed in the following test designed to capture rigorous duty cycle often seen in harsh applications with temperature / pressure extremes and a high speed and cycle count (see Table 1).

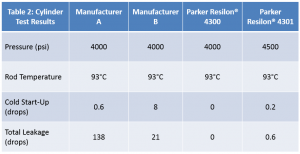

Parker’s Resilon™ 4300 polyurethane and Parker’s water resistance polyurethane 4301 were tested against 2 other manufacturers’ products. The sealing solutions was a BT U-Cup, BR Buffer ring, 4733 wear ring and AH double lipped canned wiper depicted below. The 4301 was tested at a higher temperature and pressure.

Results: ZERO LEAKAGE

There was zero leakage from Parker’s rod seal package featuring Resilon™4300 polyurethane seals over 309,000 cycles, whereas both Mfg A and Mfg B seals leaked throughout the test.

Resilon™ 4301 was tested at even higher temperatures and pressures. To keep pace with future technological advancements in cylinder applications sealing requirements will become even more challenging.

The results of Parker’s 4301 material under an even more

challenging duty cycle than Mfg A and Mfg B are shown in table 2 – only 0.6 drops.

These results are typical of Parker rod sealing solutions and span a wide range of challenging applications for hydraulic cylinders.