Article re-posted with permission from Parker Hannifin Sealing & Shielding Team.

Original content can be found on Parker’s Website and was written by Vivek Sarasam, heavy duty mobile Sr. application engineer, and Jeffrey Labonte, market manager.

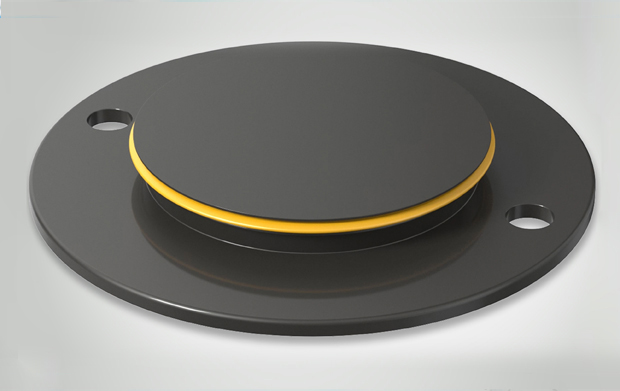

Roll2Seal® is an all-new sealing solution developed by Parker Prädifa for easy and effective closure of bores in non-pressurized applications. The clever, patent-pending design combined with an equally new assembly process enables simple and accurate installation of the seal, which rolls into its seat undamaged and without a lead-in chamfer.

What can be done if a bore requires radial sealing but lack of a lead-in chamfer prevents the installation of a seal? A situation like this occurs, for instance, when an existing bore should be closed with a cover and space around the bore is too small for a classic flange seal. A seal would not survive an attempt to install it in a bore without a lead-in chamfer. Part of the seal would be sheared off at the edge of the bore even if the edge was chamfered or rounded.

The principle: rolling instead of sliding

The Roll2Seal® concept solves this problem. Instead of destructively squeezing the seal at the critical edge, it is simply designed to roll across it. This is achieved by providing the cover with a geometry which, together with the edge of the bore, forces the seal to rotate. Subsequently, the triangular cross-section of the seal makes it possible for the seal to roll off at the dangerous edge of the bore with a minimum seal height and thus without risk of seal damage.

Roll2Seal® -the self-retaining static sealing solution for easy and reliable closure of bores

- Innovative geometry

- No lead-in chamfer

- No deburring

- No lubrication

- Immune to unbroken edges of the bore

- Metal or plastic cover

- Available in pre-assembled condition

- Easy installation

- Suitable for repeated and overhead installation

- Space- and cost-saving

Practical Applications are found

- where bores already exist for subsequent installation of additional component assemblies but require effective temporary or permanent sealing (e.g. for test runs or shipping),

- where lubrication during the assembly process is not possible,

- where non-pressurized systems require reliable sealing without screw connections.

Check out the video and see how it works:

For more information about these new self-retaining static seals from Parker, contact Gallagher Fluid Seals today. GFS is an authorized distributor of Parker.