High-Pressure, High Eccentricity Seal Solution Demonstrates 50% Improvement

On pressure and side-load performance of a fluid application

Recently, a customer was having difficulty with a seal failure on a fluid power application. The high-pressure, high-eccentricity seal operates in conditions up to 200,000 pv at 3000 psi and could not exceed maximum shaft deflection of 0.005″.

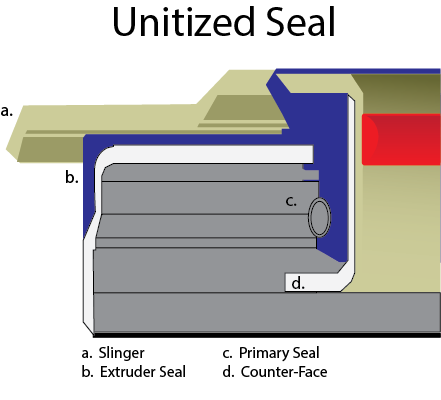

Unitized seals for input and output pinions in gear boxes, axle wheel ends, and trunnion seals

Vanseal works with these types of seal applications frequently and used a Unitized Seal that uses several components to address each of the various sealing challenges.

Vanseal’s solution for its high-pressure, high-eccentricity seal incorporated these key elements:

- Primary Seal Lip – Made from a high-modulus elastomer, to reduce lip extrusion and inversion under pressure, better distributing high-pressure forces to enhance sealing

- Machined PTFE Backup Lip – Used to reduce the risk of extrusion and inversion of the Primary Seal Lip

- Support Washer – Designed to close the extrusion gap between the seal ID and shaft under high, shaft-deflection conditions

- Excluder Lip – Works to keep contaminants from entering the assembly system

- Metal Case – Serves as a carrier for the seal components creating a single unit to install, and thus reducing instances of installation errors caused by multi-piece installations and reducing individually purchased and inventoried items.

The original article can be found on Vanseal's website.

To learn more about Vanseal's products, speak to a Gallagher representative today by calling 1-800-822-4063