service life.

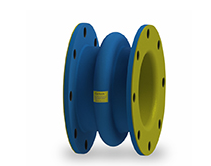

Style 404 Expansion Joints are specially designed for full vacuum abrasive service applications. The tube material is a proprietary urethane formulation. Style 404 can be constructed as a single or multiple arch design. It can also connect pipe flanges in concentric or eccentric tapers, to join piping of unequal diameters.

Case Study: Chemical Processing

Industry

Chemical Processing

Observation

A stainless hosing was used and would continuously fail due to abrasion on the leading edge of the hose. The hosing would last for 3 to 6 months before replacement.

Background

This chemical plant based in Southern United States produces fluid catalytic cracking (FCC) catalysts, co-catalysts and additives used by petroleum refineries to convert crude oil into gasoline, other transportation fuels, heating oil and petrochemical feed stocks. Kaolin based microsphere intermediaries are used to manufacture the FCC catalysts and co-catalysts.

Operating Conditions

1. Size: 4” x 10.5” 404 ABRA-LINE™ Expansion Joints

2. Temperature: 140°F

3. Application: Transfer piping

4. Media: Zeolite based catalysts (42% total solids), pH 13

5. Flow: 200 Grams per minute

Solution & Benefits

The 404 ABRA-LINE™ was chosen as the best solution, and has now been in service for over 2 years yielding more than 4x the service life of the stainless steel hosing.

Proposition Value

Garlock Expansion Joints offer superior performance, reliability and service life. This results in an improvement in plant safety, an increase in the mechanical integrity of equipment and allows customers to gain a competitive advantage in the market place.

If you need assistance determining which expansion joint is right for your specific process, please contact our engineering department.