What do you do when you need an urgent spare part for a made-to-order seal? What do you do when special seals are required for a short production run of 400 machines? It’s hard to know. Here’s where the Freudenberg Xpress® experts come into play.

From Tiny to Huge

To these sealing specialists, it doesn’t matter whether their customers need seals with diameters of just two millimeters or a full twenty meters – a size that can be found in wind turbines or hydro-electric plants. Nor does it matter whether the order is for a standard seal or a customer-specific product. “Within 24 hours of the incoming order’s arrival, we can produce and deliver up to 50 units,” Furrer said.

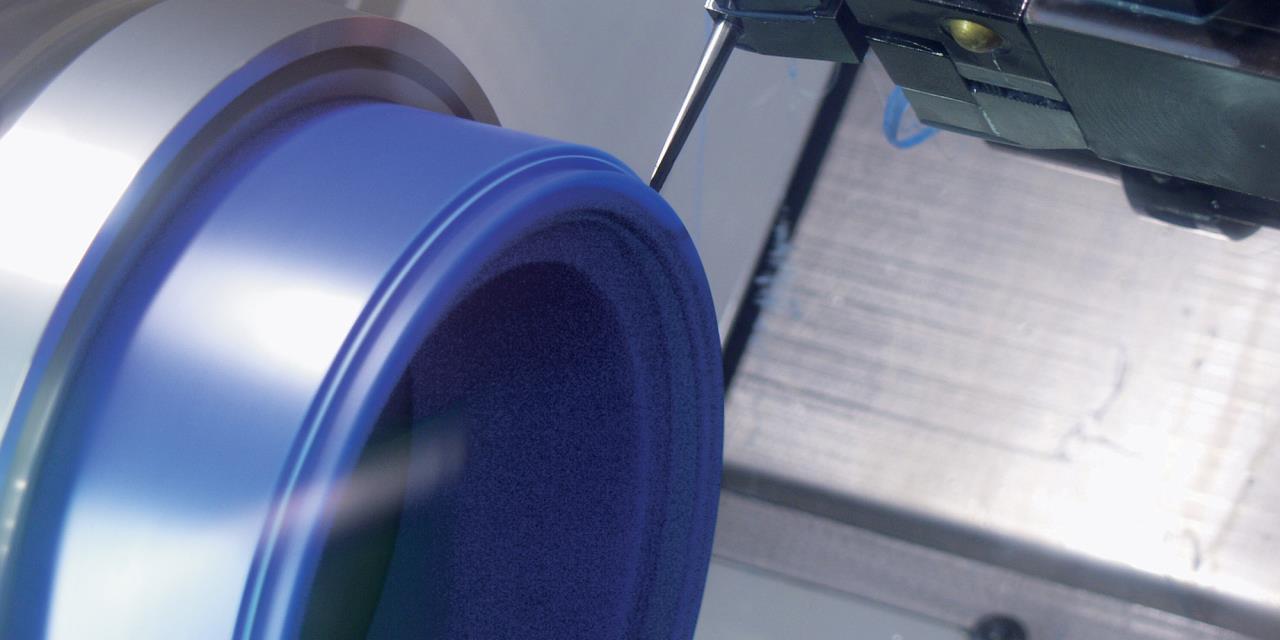

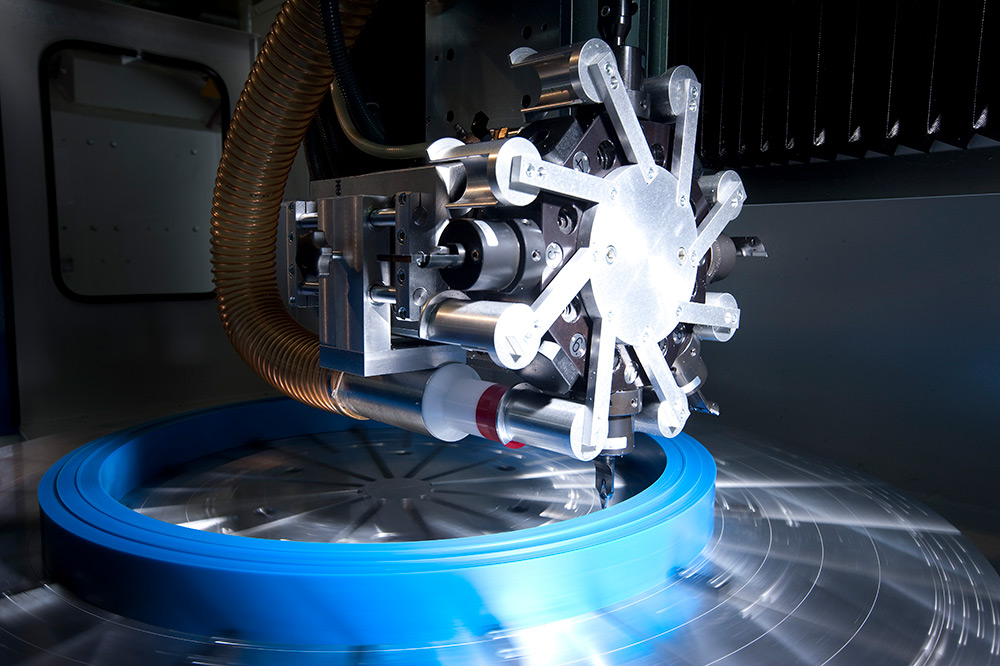

Turned, Milled and Welded Solutions

In single-unit production, specially developed turning and milling machines are used to manufacture the seals. “With this so-called machining production process, we can produce seals more economically and much more quickly than the conventional injection molding process – and with the highest quality,” Furrer said. For large seals with a diameter of up to twenty meters, Freudenberg Xpress turns to welded polyurethane seals, which are manufactured in an automated process. They stand out for their high-quality welding seams, which enable the seals’ characteristics and lifespan to be maintained. This is a clear advantage over solutions using industrial adhesives or out-of- date welding techniques.

Original Profiles and Materials Used

Freudenberg Xpress uses original Freudenberg profiles and materials, so these rapidly produced seals may be made of various elastomers and plastics. Among other options, they include elastomers such as Fluoroprene® XP 41, which is employed in the food industry, and PTFE materials such as B602. High-quality polyurethane is also available as a material. It is impressive for its robustness, resistance to severe heat and cold, and outstanding mechanical characteristics. These attributes guarantee the seals’ high quality.

“To make the ordering process as convenient and up-to-date as possible, we now offer an Xpress configurator on EASY, our online ordering platform”

Online Configurator Facilitates Ordering Process

Freudenberg Xpress has special offering in its selection: “To make the ordering process as convenient and up-to-date as possible, we now offer an Xpress configurator on EASY, our online ordering platform,” Furrer said. With just a few clicks, the customer can easily configure the required seal on his own. The process is based on a preselection of Freudenberg seal profiles, such as rod and piston seals or wipers. At the same time, the customer can determine the desired product’s material, size and quantity and immediately trigger the order. No other provider of sealing systems now offers this service.

Short Production Runs Available in Several Days

Short Production Runs Available in Several Days

Freudenberg Sealing Technologies is impressive for yet another offering: the cost-effective production of short production runs of up to 500 seals. They can be delivered in just a few days. Here Freudenberg Sealing Technologies turns to so-called rod load technology, which permits automated production without an employee's repeated manual intervention. With this short production run service, Freudenberg's fast-delivery experts are responding to desires of industrial customers, who would otherwise not even pursue some projects in the first place due to their expense.

Ongoing Development of the Service

In Germany, Freudenberg Xpress manufactures at the company’s Schwalmstadt plant. Its central location facilitates shipments throughout the country. Freudenberg Xpress has 11 other locations worldwide. Timo Furrer and his staff have the goal of continually expanding the service. In this way, the digital course taken by the online configurator is due to be pursued systematically. In addition, Freudenberg is further developing its existing technologies and products on an ongoing basis. "This will help us expand our position as a high-performance service provider,” Furrer said.

This article has been reposted, with permission, from Freudenberg's NEWS section of their website.