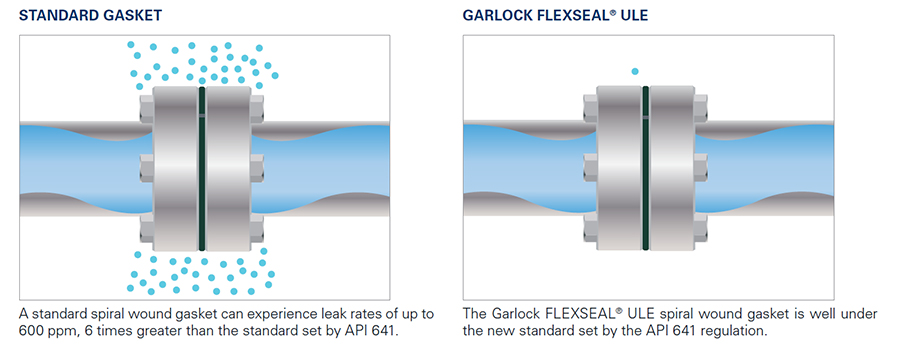

Garlock has expanded their Ultra Low Emissions family of products to include a spiral wound gasket. The FLEXSEAL® ULE is designed for use where leakage control is critical and the aggressive application requires a spiral wound design. It’s manufactured using high performance graphite, and offers maximum protection against oxidation. The standard design includes an inner ring and outer ring, as well as preformed metal wire to enhance compressibility and sealability. The FLEXSEAL® ULE spiral wound is another product born from Garlock’s customer driven innovation.

Values & Benefits

- API 6FB

- Average leak rate recorded of 1.4 ml/min

- Low Emissions (CFET)

- Provides average leakage rates of 10 PPM (parts per million)

- Oxidation Resistance

- Offers maximum protection against oxidation for greater reliability and longer service life

- No aging or fatigue under dynamic load, even at elevated temperatures

- Manufacturability

- Available in standard lead-time

Configurations

- Standard Flexseal Spiral Wound configurations: RW/RWI/ SW/SWI

- Materials and dimensions per ASME B16.20

- Materials available include various series 300 stainless, Hastelloy®*, Inconel®** and titanium, custom materials are also available

FLEXSEAL ULE FROM GARLOCK IS IDEAL FOR

Thermal Cycling - Compressibility and recovery of high performance graphite combined with custom winding technology and processes that provides excellent chemical resistance and performance operating uncompromised in a wide temperature range Industries where stringent fugitive emission requirements are found Pressurized process equipment with evaporated sources, such as waste water treatment and storage tanks.