Mechanical Seals

Mechanical Face Seals

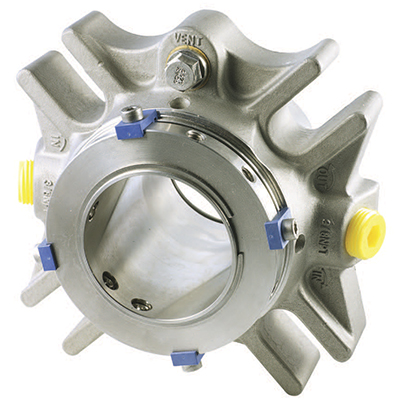

Eagle Burgmann Mechanical Seals are fully pre-assembled and precisely installed component seals incorporated in a cover and shaft sleeve. The seals are installed in pumps in a wide range of industries including chemicals, water supply, paper production, food processing and many other applications. Cartridge seals are easy to fit, and they keep your running costs down.

Over the past twenty years, Eagle Burgmann Mechanical Seals have demonstrated a proven track record in sealing applications on all standard pump types. This practical seal design has been successfully established in the market.

The Cartex® range now includes single and double seal versions for all standard operating modes as well as special versions, for example for sterile applications or installation in positive displacement pumps. The below seals are Cartex ANSI Single seals; all with Carbon Graphite faces. Seals are offered in both Standard and Big Bore sizes. Four different O-ring elastomer materials are available for all sizes: FKM, FFKM, Aflas and EPDM.

Rotary Seal applications can be very demanding depending. GFS Engineers are available to consult on any Rotary Sealing application. Click here to contact a GFS Engineer.