Gaskets

Gaskets

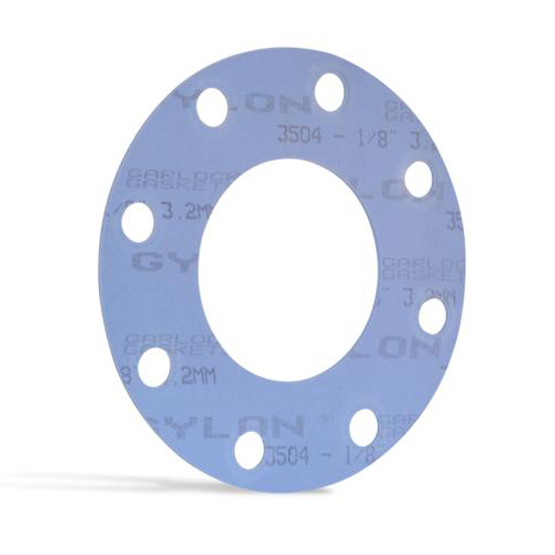

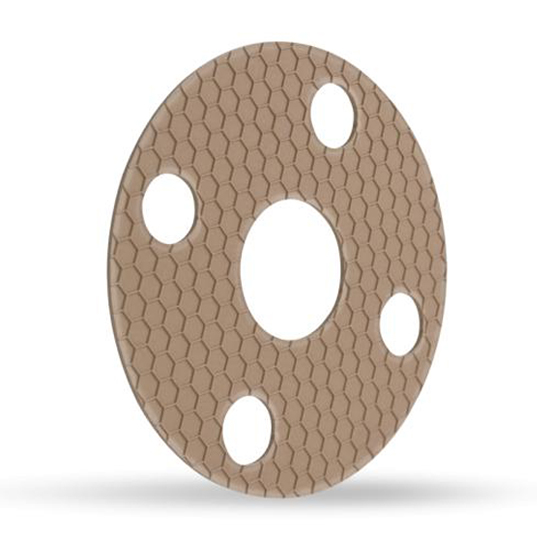

A Gasket is a deformable material that is used to create a static seal and maintain that seal under various operating conditions in a mechanical assembly. GFS offers a range of gasket types, profiles and materials. The most popular are sheet gaskets. These gaskets are punched or cut from a larger sheet of material. Also referred to as ‘Flange Gaskets’ these parts are utilized at the joining of two pipes, and seal within the flange.

Spiral Wound Gaskets are made with an alternating combination of formed metal wire and soft filler materials. A V-shaped crown centered in the metal strip acts as a spring, giving gaskets greater resiliency under varying conditions. Filler and wire material can be changed to accommodate different chemical compatibility requirements.

Prevent Leakage Between Two Mating Surfaces

Specialty gasket products offered for purchase include a range of expanded PTFE Joint Sealant, Gasket Tape, and Sanitary Gaskets. The Joint Sealant and Gasket Tape can be described as ‘Form in Place’ gaskets. Rather than fabricating a finished gasket shape, these products are manufactured on a roll, and based on their thickness and cross section are cut to length and pressed into the flange. Sanitary gaskets are a class of specialty gaskets used widely in the pharmaceutical and processing industries. Also referred to as Tri-Clamp gaskets, these seals fit within clamp connections and sanitary pipelines.

Optimizing gasket performance can be a very complicated process. If you require the input or design assistance of a GFS engineer for your application, please contact GFS here.

A Ring Type Gasket is positioned inside of the flange bolts and around the pipe bore. In a raised face design it sits on the raised surface. This design requires less material and less cutting, can be installed without completely dissembling the joint.

Like the ring-type gasket, this can also seal raised flange faces, but will have an OD the same as the flange. That means it needs holes for the securing bolts to pass through, and these help locate the gasket on the flange, making alignment easier.

GFS offers full and partial sheet material for the same materials it offers its fabricated gaskets. These materials are in stock and available for purchase.

Spiral-wound gaskets comprise a mix of metallic and filler material. Generally, the gasket has a metal wound outwards in a circular spiral with the filler material wound in the same manner but starting from the opposing side. This results in alternating layers of filler and metal. The filler material in these gaskets acts as the sealing element, with the metal providing structural support.

Joint Sealant, the first form-in-place gasket, was invented by Gore more than 40 years ago. It is a time-tested sealing solution for steel flanges with large diameters, rectangular or irregular shapes, and rough or pitted surfaces. When compressed, this soft, conformable cord forms a thin yet strong seal. It can also seal applications where available bolt loads are low.

Sanitary gaskets are designed to seal hygienic clamp unions with a nearly flush interface, preventing the entrapment of any media within a dead space that can lead to microbial growth and contamination. In addition, the flush interface helps prevent erosion of the elastomeric gasket that could contaminate the process stream.