PTFE Rotary Seals

PTFE Rotary Seals

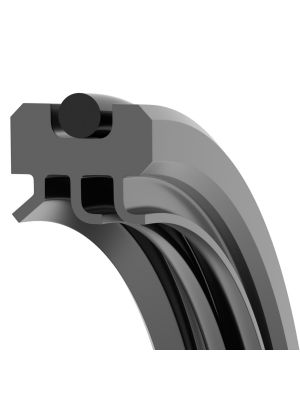

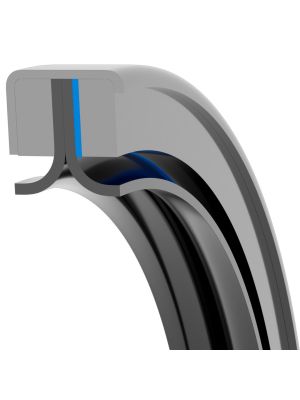

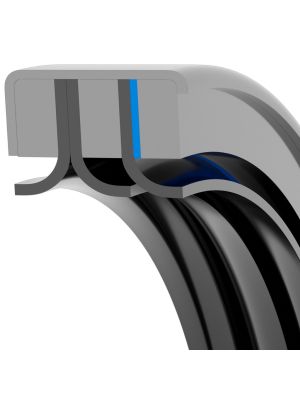

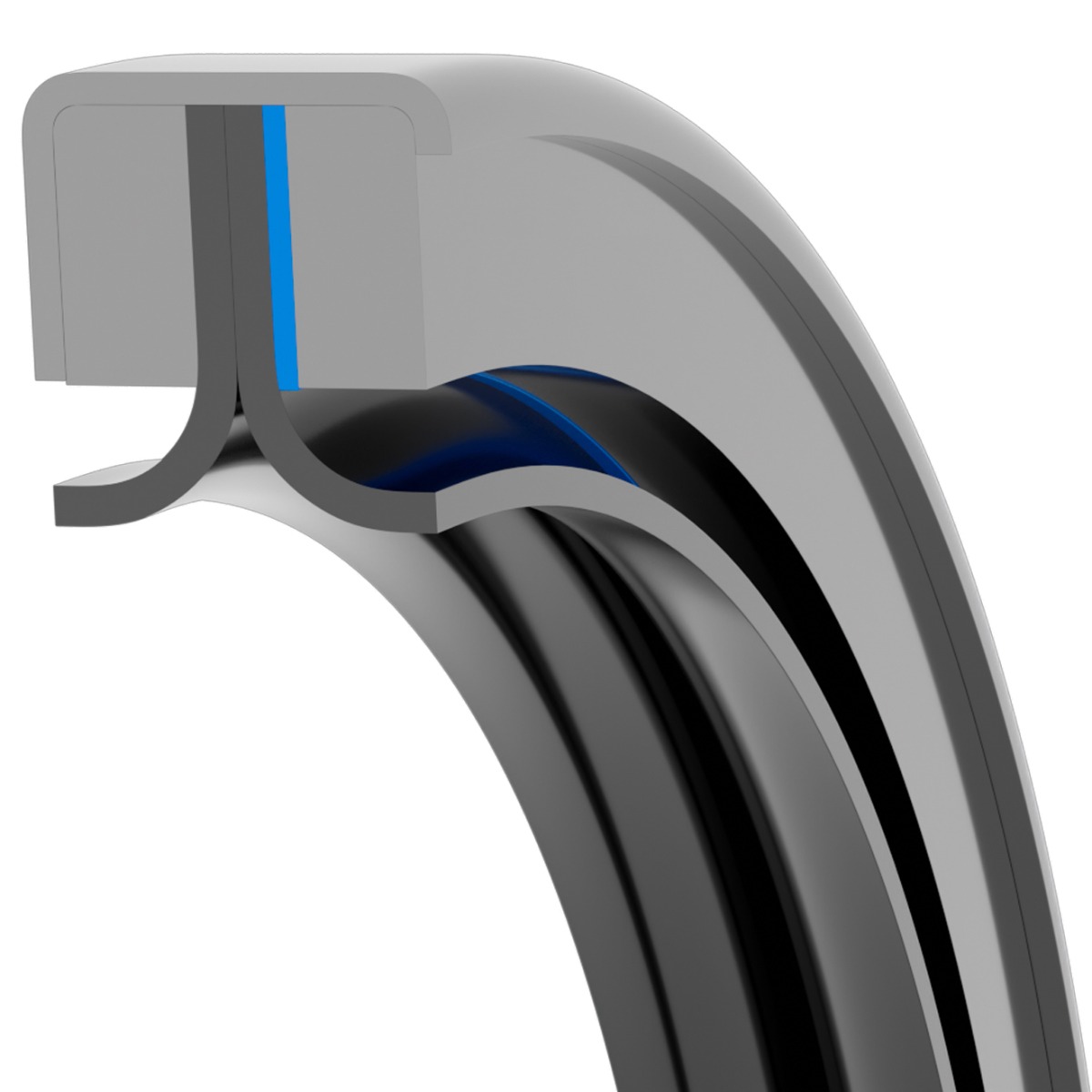

PTFE Rotary Lip seals are a class of rotary seals that feature a PTFE ID lip that seals dynamically, and an OD that rests statically in the bore. GFS features three different types of PTFE Rotary Lip seals for purchase on this website. PTFE Canned Lip Seals offer a machined or formed PTFE lip or lips, sandwiched between gaskets. The metal can keeps the seal in place through an engineered press fit. A similar class of seals replace the metal can with an O-ring that keeps the OD of the seal from rotating. PTFE lip seals with O-rings installed on the OD operate at lower rotary speeds than those with metal cans. Finally a series of rotary spring energized seals that contain a machined flange that is clamped between two hardware components to ensure that seal stays static in the hardware.

PTFE Rotary Lip Seals can operate at much higher speed than oil seals, however they do have their limits. Pressures up to 4500 psi can be sealed but are on the very high end of rotary sealing pressures. Please contact GFS engineering for assistance with your PTFE Lip Seal application. These seals can be customized for application specific needs in both material and geometry.

Rotary Seal applications can be very demanding depending. GFS Engineers are available to consult on any Rotary Sealing application. Click here to contact a GFS Engineer.

Materials

Glass / Moly Filled PTFE

Virgin PTFE containing 5% glass fiber and 5% molybdenum disulfide (MoS2). Added in various amounts these fillers work to increase hardness, stiffness and wear. Material data sheet can be viewed here.

Carbon Graphite PTFE

GFS Carbon Graphite Filled PTFE is a high performing material containing 23% carbon and 2% graphite. This material reduces creep, increases hardness and elevates thermal conductivity of PTFE. This material offers strong wear resistance and low friction properties. Material data sheet can be viewed here.