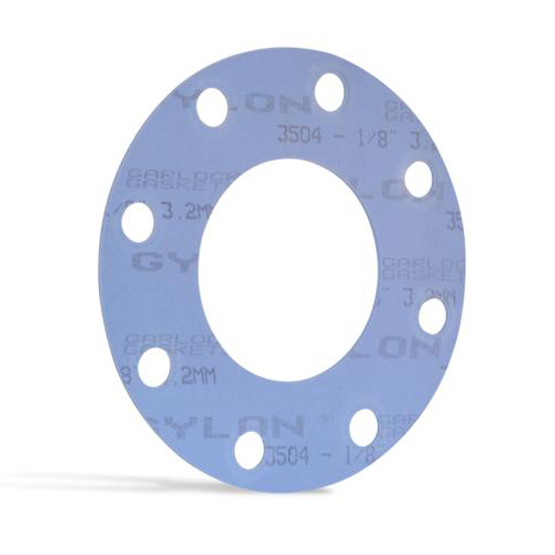

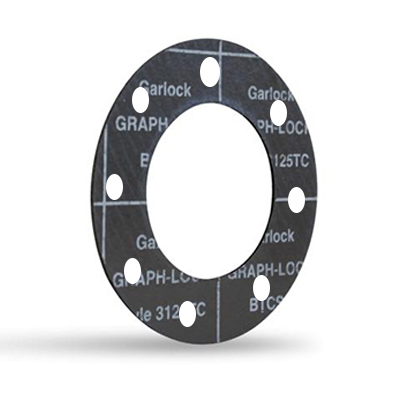

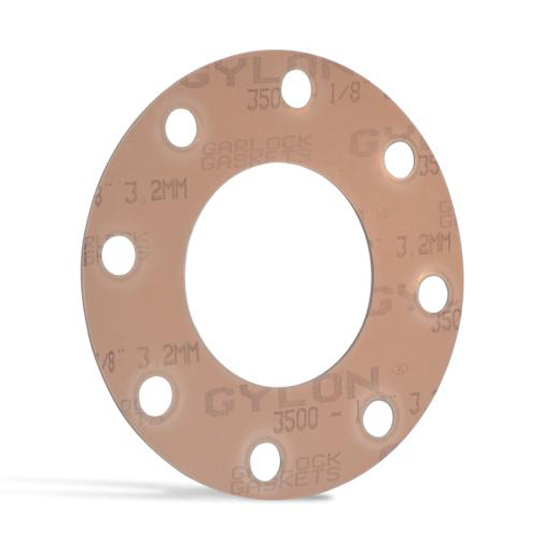

Full Face Gaskets

Full Face Gaskets

Like the ring-type gasket, Full Face Gaskets can also seal raised flange faces, but will have an OD the same as the flange. That means it needs holes for the securing bolts to pass through, and these help locate the gasket on the flange, making alignment easier. Extending out to the flange OD has the added benefit of filling the gap between bolting surfaces, which stops dirt getting in. However, the joint must be completely dissembled for installation.

Specifying a full-face gasket requires the ID (same as the pipe bore), the OD (same as the flange OD), bolt circle diameter (the diameter on which all the bolt hole centers are located), number of bolt holes (and spacing if they’re not be regular – which would be very unusual for a flange), and gasket thickness.

Prevent Leakage Between Two Mating Surfaces

GFS fabricates Full Face Gaskets from all industry materials. Materials are in stock, and standard Full Face Gaskets can be shipped within 24 hours.

Optimizing gasket performance can be a very complicated process. If you require the input or design assistance of a GFS engineer for your application, please contact GFS here.

The compressed, non-asbestos (CNA) gasketing line offers a variety of elastomers that provide exceptional sealability and excel in a wide range of services. The unique blend of aramid fibers, fillers and elastomeric binders provides improved torque retention and drastically lowered emissions levels.

Garlock® GYLON® gasketing is a family of severe service PTFE gasketing materials manufactured using a proprietary process that imparts unique physical properties that are not obtainable through conventional manufacturing methods. ePTFE materials are made of 100% monoaxially expanded PTFE (ePTFE), using Gore’s expansion technology to create a high degree of fibrillation.

GFS Graphite materials, including Garlock Graph-Lock® and Klinger® Laminated Graphite, are composed of pure, exfoliated flake material. These materials excel in extreme conditions and withstands high temperatures, high pressures, and aggressive chemicals. Graphite materials also provide excellent resistance and is proven to be fire-safe.

High temperature gasketing excels in the harshest conditions—intense heat and high pressure. These high-performance gasket materials have been laboratory tested for fire safety. They maintain an effective seal during pressure and temperature fluctuations, and their excellent torque retention lowers leakage rates and reduces maintenance time.

Garlock® Inorganic Fiber Gasketing offers excellent thermal stability with minimal weight loss, reduced creep relaxation and improved torque retention. The inorganic fibers have excellent thermal and oxidation resistance, withstanding a continuous operating temperature of up to 550°F (290°C), and maximum spike of 800°F (425°C).

Low cost gaskets that utilize vegetable fiber to seal in low pressure, low temperature applications.

GFS offers Full Face Gaskets in popular elastomeric materials. NBR, FKM, EPDM, Neoprene and Silicone, amongst others.