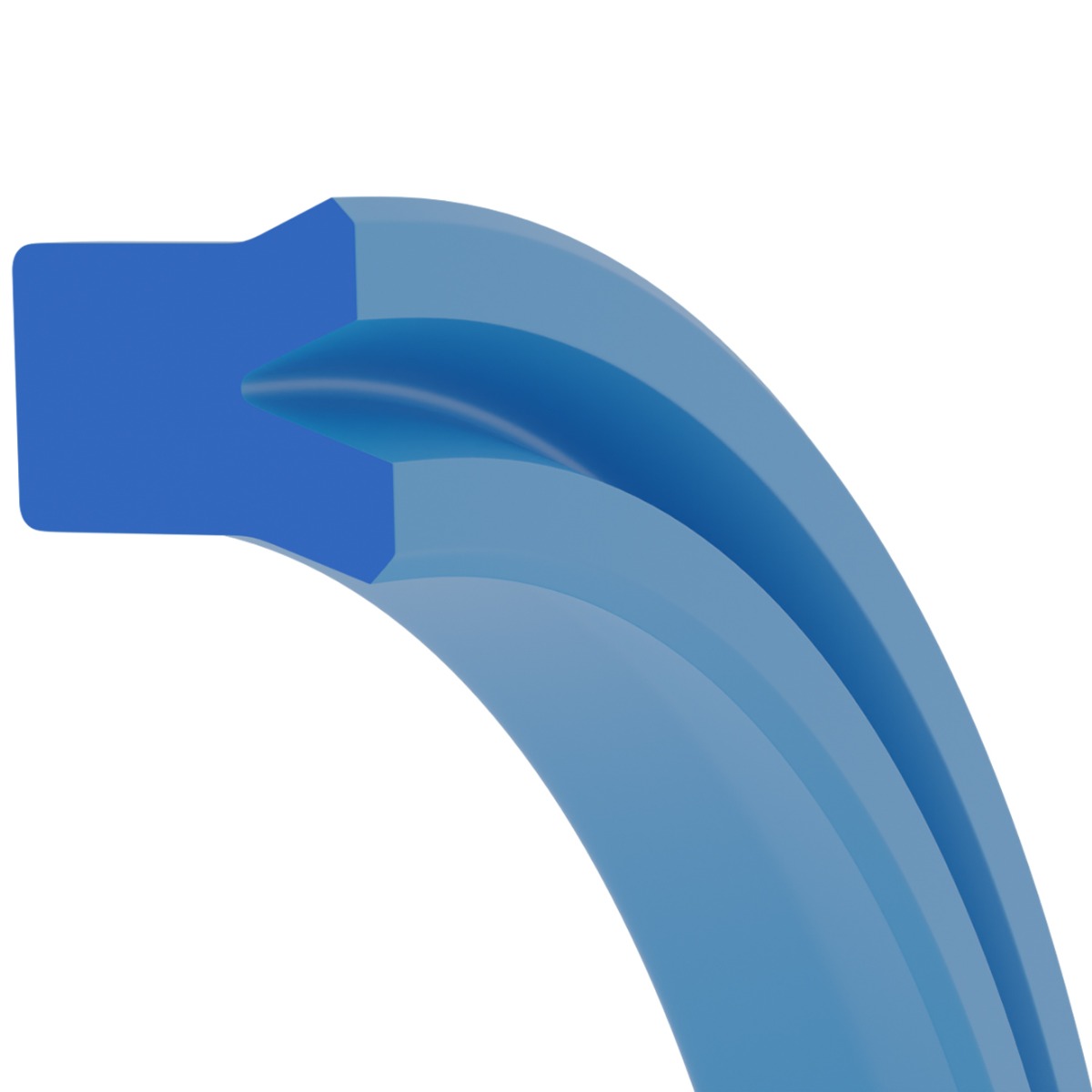

Piston Seals

GFS Piston Seals

GFS Piston Seal profiles are designed and manufactured to optimize leakage control. Piston Seals offer sealing contact between the cylinder head and the cylinder bore, allowing pressure to build during stroke movement. GFS Piston Seal profiles are available as single acting (pressure from one side) or double acting (pressure from both sides). Available GFS Piston Seal profiles are available for purchase by selecting the profile image below or viewing all GFS Piston Seal profiles together here.

Prevent Leakage

Different Piston Seal profiles offer distinct advantages depending on the sealing application. Temperature, Pressure, Stroke Speed and other environmental considerations would lead users to different profiles and materials. Primary Piston Seal materials are Polyurethane and PTFE blends. Specific GFS Piston Seal materials are outlined below.

Piston Seal applications can be very demanding on the seals. GFS Engineers are available to consult on any Piston Seal application. Click here to contact a GFS Engineer.

Materials

Polyurethane

GFS Polyurethane 95A is a 95 durometer thermoplastic polyurethane material appropriate for the vast majority of hydarulic piston seal applications. It offers some hydrolysis resistance. Material data sheet can be viewed here.

Carbon Graphite PTFE

GFS Carbon Graphite Filled PTFE is a high performing material containing 23% carbon and 2% graphite. This material reduces creep, increases hardness and elevates thermal conductivity of PTFE. This material offers strong wear resistance and low friction properties. Material data sheet can be viewed here.

Bronze Filled PTFE

GFS Bronze Filled PTFE increases the strength and wear resistance of the seal. The Bronze filler increases dimensional stability and lowers cold flow and creep. Material data sheet can be viewed here.