Rotary

Rotary Seals

GFS Rotary Shaft Seals are designed and manufactured to seal within rotating, oscillating and swiveling applications. The primary goal of any rotary shaft seal is to retain lubrication within the system and prevent contamination from outside the system.

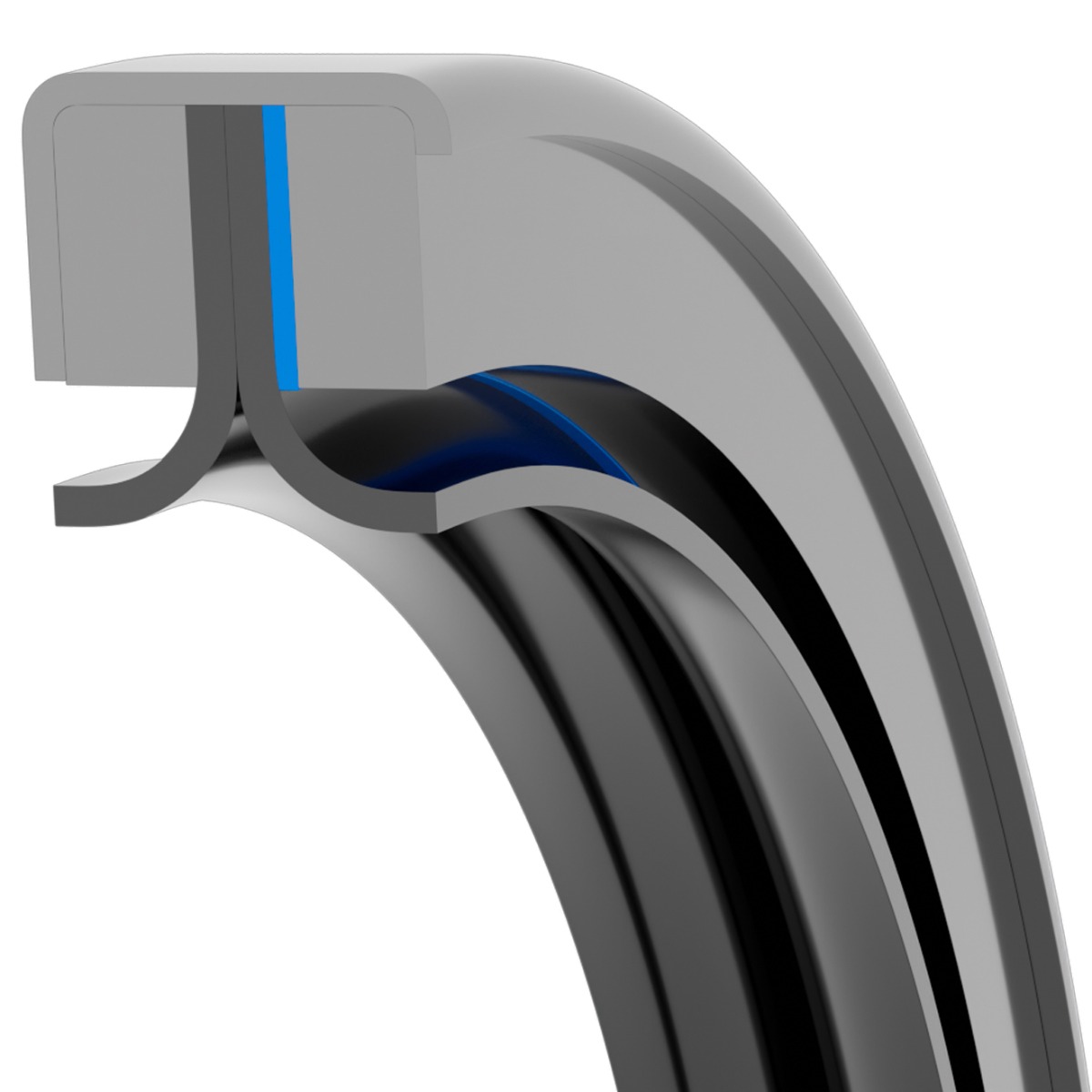

Low-Pressure, Low-Speed Rotary applications can utilize bonded radial oil seals, or elastomeric V-rings. Higher rotary speeds and pressures result in increased thermal and frictional properties, requiring higher performing profiles and materials to achieve sealing performance and maximize seal life. These seals, often made from a PTFE material, will utilize either an O-ring on the outer diameter (OD) or, at higher pressures, a metal can on the OD of the seal to maintain a press fit in the seal housing. These seals can be designed with a wide range of lip configurations to optimize lubrication retention and contaminant exclusion.

Retain Lubricants, Exclude Contaminants

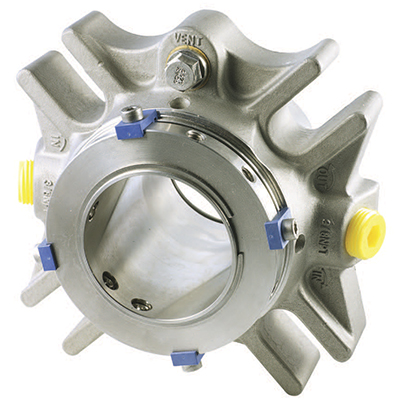

Mechanical Seals are a specialty rotary seal utilized for sealing pumps where leakage is not an option. Mechanical seals deliver higher sealing performance compared to braided pump packing, which is offered in its own section here, despite braided packing being an appropriate and high performing solution under the right circumstances.

Extreme rotary sealing applications are amongst the most challenging engineering problems to solve with respect to seals. Conditions such as high surface speeds, shaft misalignment and run out, extreme pressure (above 5,000 psi), and corrosive chemical media all typically require specialized rotary seal profiles and materials. Contact the GFS Engineering Department here to discuss your rotary sealing needs.

GFS Oil Seals, or rotary shaft seals, have elastomeric sealing lips that are very effective at retaining lubricants. Various profiles offer different case materials, exclusionary lip configurations and garter springs.

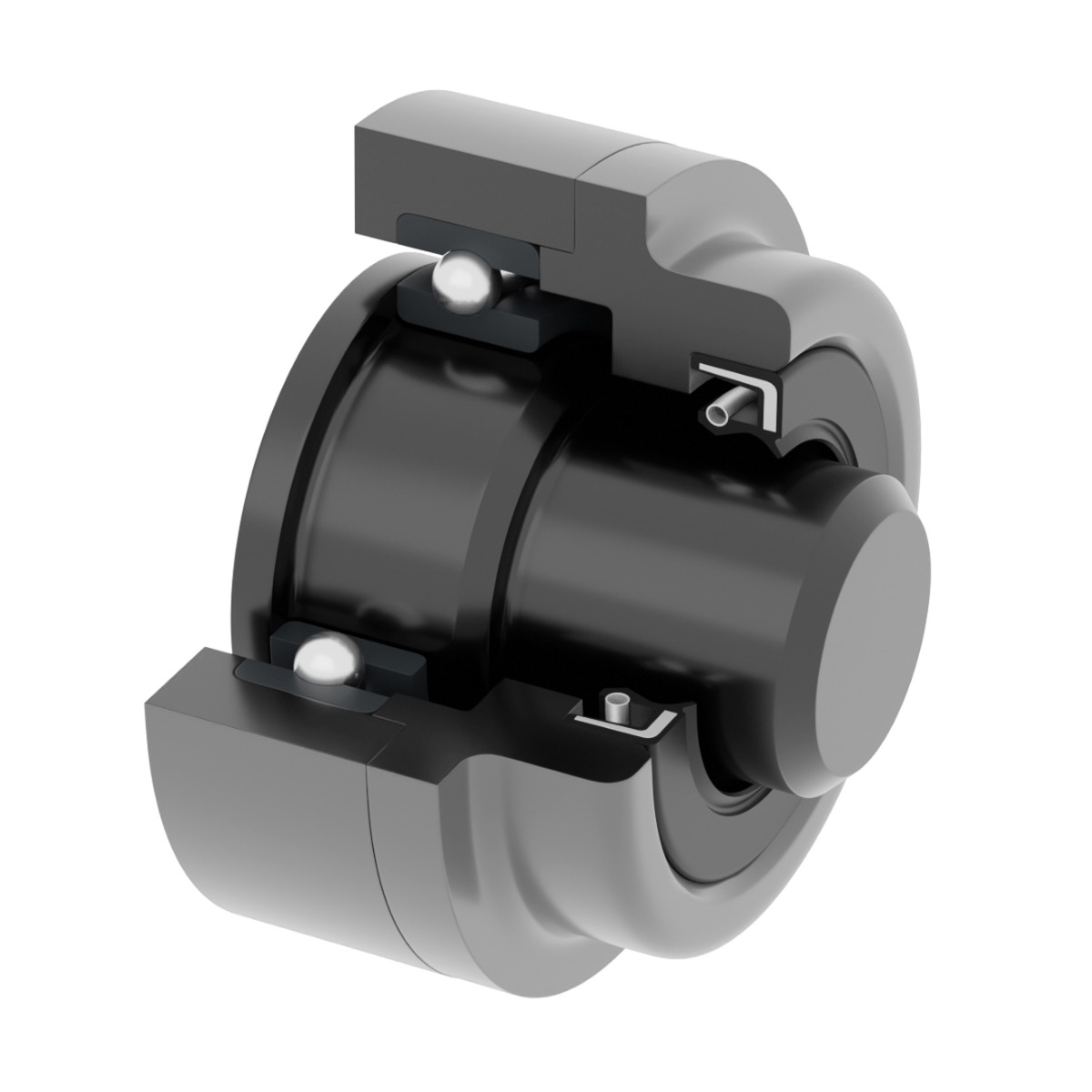

KLOZURE® Oil seals from Garlock® are available in a wide variety of configurations to meet the requirements of major industries. MILL-RIGHT® materials are used on all elastomeric seals for superior bearing protection.

OEMs worldwide know Clipper Oil Seals for their ability to provide superior performance in the most demanding and critical applications. A one-piece molded construction and the ability to provide application-specific designs, if needed, are just a few of the reasons Clipper seals are specified for critical applications.

GFS PTFE Rotary Lip seals are a class of rotary seals that feature a PTFE ID lip that seals dynamically, and an OD that rests statically in the bore. These seals can operate at higher pressures and speeds than seals with elastomeric sealing lips.

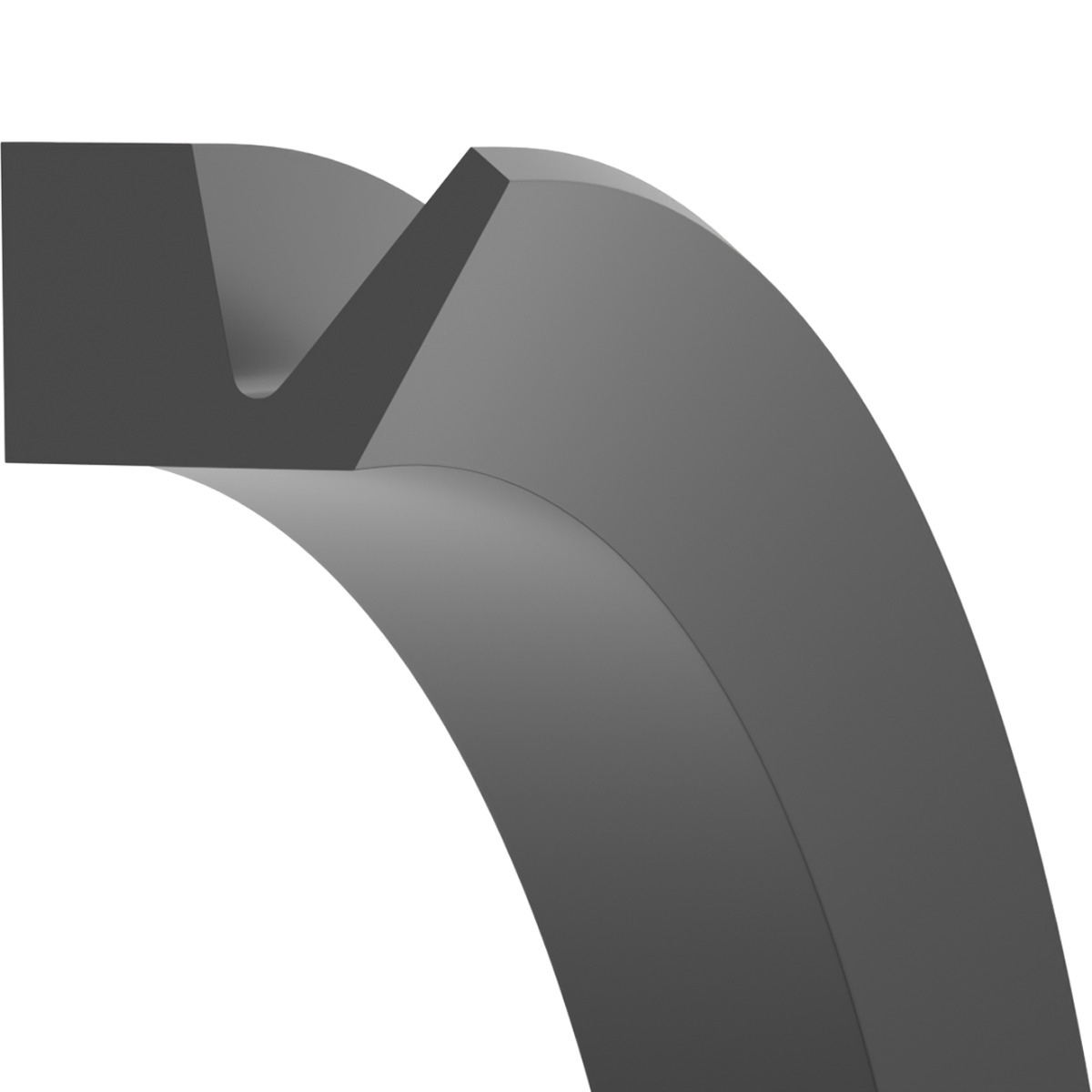

A V-Ring seal is a one-piece all rubber rotary shaft seal, which stretches to fit on a shaft. It is held in place by its own tension on the shaft and the seal axially mounts against a stationary counter-face.

Eagle Burgmann Cartex ANSI Single and Double seals; all with Carbon Graphite faces. Seals are offered in both Standard and Big Bore sizes. Two different O-ring elastomer materials are available for all sizes: FKM and FFKM.