Common O-Ring Elastomer Properties "Cheat Sheet"

While there are dozens of unique elastomers used for specific applications throughout the world, this GFS "elastomer cheat sheet" discusses the properties of the most common types of o-ring elastomers. If your equipment or product uses o-rings, it more-than-likely contains one of these nine elastomer types.

Learn about:

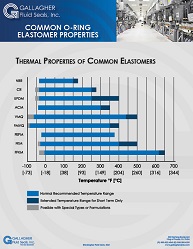

- The thermal properties of the most common o-ring elastomers: What the normal operating range should be, what the maximum temperature range for a short time only, and the minimum temperature range that can be achieved with special formulations

- Advantages and disadvantages of the most common o-ring elastomer types

- Comparison of the properties/resistance capabilities of each common o-ring elastomer.

- Want to know heat resistance, permeability, tensile strength, or abrasion resistance?

Download our elastomer "cheat sheet" to learn about which one may be best for your specific application.

Surface Finish Ra Advantages and Disadvantages Tech Bulletin

As we continue the GFS series on Surface Finish, this next tech bulletin will help you understand the advantages and disadvantages of the most commonly used method of measuring surface finish: Ra

Ra is the arithmetic average of the absolute values of the profile height deviations from the mean line, recorded within the evaluation length.

Ra monitors production and is a very stable and repeatable process, hence why it is the most commonly used method.

It is a good parameter when a manufacturing process is under control and conditions are always the same – i.e. Cutting tool, Speeds, Feeds, Cutting Fluids, etc.

It is meaningful for random surface roughness, machined by tools that do not leave marks on the surface – i.e. Grinding and Polishing.

But Ra also has some disadvantages. You can learn them by downloading our Ra Surface Finish Tech Bulletin.

For more information about o-rings or surface finish, contact Gallagher Fluid Seals today.