Gallagher Fluid Seals is a Parker Distributor is proud to be proud to be one of the few premier distributors to qualify as a “Parker Seal Technology Center (STC)”.

Reduce Exhaust Leakage in Heavy Duty Engines by 80 Percent with an Air Duct Seal

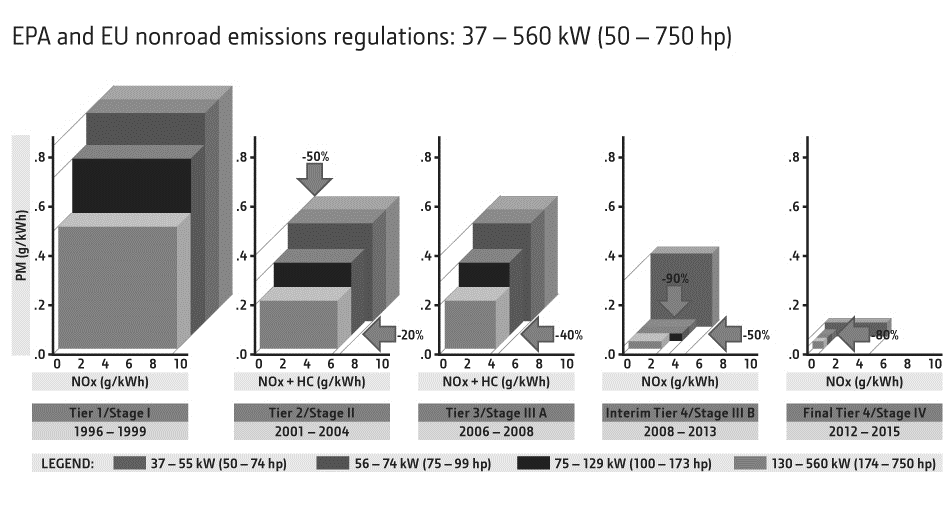

Increased emission restrictions are requiring engine manufacturers to conform to Euro 6 and Tier IV regulations to reduce exhaust leakage 80% or more. In order to achieve these new standards, engines with extreme temperatures coupled with a high amount of vibrational movement, need to have highly engineered sealing solutions. Applications with predetermined mating components cannot always be changed, so the need for a sealing solution with a similar coefficient of thermal expansion is needed.

What is the problem in existing exhaust applications?

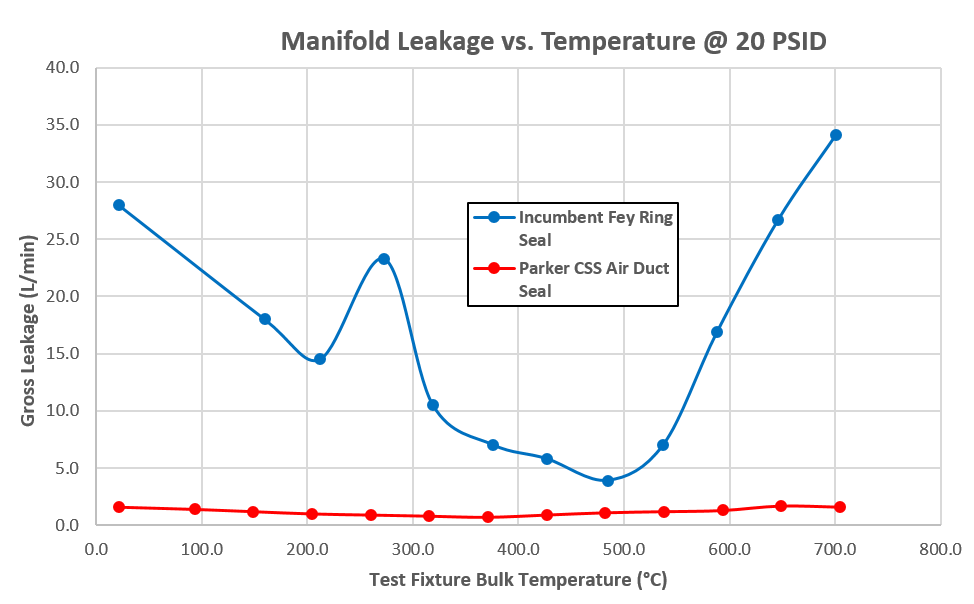

Most heavy duty diesel engines can reach exhaust gas temperatures upwards of 1292°F(700°C) while subjected to constant vibrations. These engine vibrations can cause havoc when a seal needs to be maintained on the exhaust line. Vibrations from the engine cause rotation, cavity offsets, pivoting, and reciprocation which become difficult to seal against. Movement, pressure cycling and thermal cycling require an engineered solution to maintain a seal under extreme application conditions. With the use of custom engineering and advanced analysis techniques, Parker is able to create custom solutions for our customers’ most difficult applications.

Parker's solution to tackle these challenges

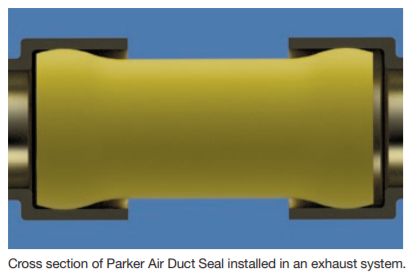

Parker’s Air Duct Seals for Heavy Duty Engines are a single piece, easy to install metal design, providing lower leak rates than traditional labyrinth piston ring seals.

The continuous single-piece metal seal design is enhanced with the use of TriCom-HT™, Parker’s proprietary high-temperature, anti-wear coating. TriCom-HT™ provides superior wear resistance, protecting the Air Duct Seal from the detrimental effects of engine vibration and thermal cycling, resulting in 80% less leakage and extended seal life.

Our Air Duct Seal design fits tightly into the mating hardware, greatly reducing leak paths. Machined grooves are not required in the mating hardware, thereby lowering your manufacturing cost.

Some key applications where this technology can be used:

- Multiple component assemblies: Assemblies where vibration causes leakage, in gasses or another fluid medium. Also in assemblies where high temp sealing is an issue due to expansion/contraction of mating hardware at the higher temps.

- Gas Turbines: Where static elastomer or metal seals cause leakage issues at high temperatures.

- Vibration isolation applications: Where isolation seals fail to stop leakage due to vibration.

- Exhaust connection between:

- EGR

- EGR Cooler

- Exhaust Pipes

- Turbo Charger

- Exhaust Manifold

Key benefits compared to competitive technology:

Parker has been able to incorporate its design experience and knowledge of metal sealing technology and material science technology to create this solution. The Parker Air Duct Seal was designed with cost savings in mind and the patented design allows for value added one-piece out of the box installation, virtually eliminating complex sealing needs. Installation of the Air Duct Seal is simple, and requires only a press fit for both sides of the seal. Some key benefits are:

- Easy to install: The seal is designed to be a press fit install using a simple hand operated arbor press. The curved features allow for the Air Duct seal to move in the cavity while maintaining contact with the mating flanges. These features are also designed to allow for offset or misalignment issues.

- Single piece out of the box lower cost option - metal design: This is a single piece out of the box rigid sealing solution providing a value-add function for supply chain by reducing part count in the Bill of Materials. Also reduces overall installation time and effort, hence lowering procurement and assembly costs.

- Anti-wear coating: Parker’s proprietary coating, TriCom HT™, is comprised of a unique cobalt-nickel alloy matrix co-deposited with chromium carbide and MCrAlY particles to provide a wear and oxidation resistant system for prolonged use. This coating is vitally important to ensure that the Air Duct Seal works as long as the end product’s life. For more information, see page D-64 and D-65 of CSS 5129.

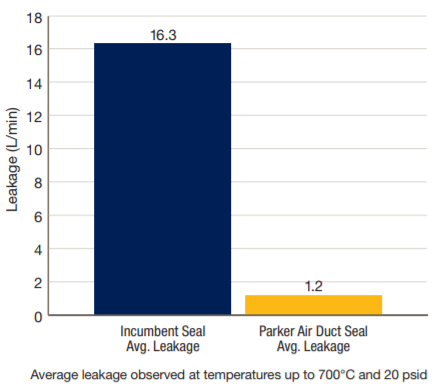

- Lower leakage rates than incumbent sealing technology: The Parker Air Duct Seal has been bench tested and field tested to seal better than the competition as seen in the graph. This is also required to meet future emission standards and exceptional leakage requirements that other seals cannot.

- High temperature and vibration resistance: The solution can operate up to 1400°F (760°C) continuous and 1550°F (843°C) maximum temperature. The design also allows for resistance due to vibration in the engine or machine.

- High corrosion resistance for long life: The Air Duct Seal uses our proprietary TriCom HT™ coating which helps resist corrosion and is better oxidation and wear resistant, hence durable enough to last the life of the application.

This article was contributed by Vivek Sarasam, Heavy Duty Mobile Senior Applications Engineer, Engineering Materials Grouo