Gallagher Fluid Seals is a Parker Distributor is proud to be proud to be one of the few premier distributors to qualify as a Parker Seal Technology Center (STC).

Parker ZP203 and Parker ZP204

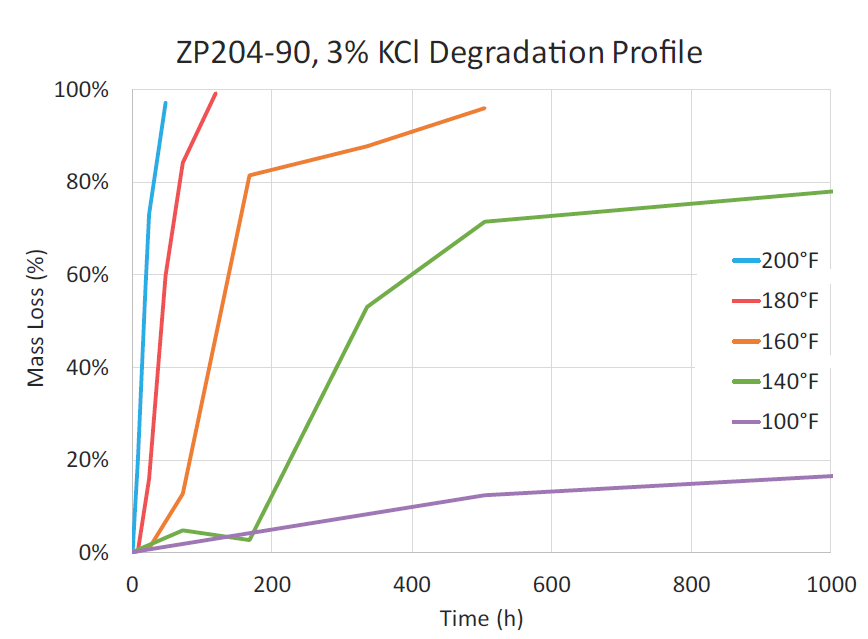

Parker’s ZP203 and ZP204 degradable elastomer compounds help to eliminate the need for coiled tubing intervention, or drill out, when utilized as a sealing element in the oil and gas completions market segment. ZP203 and ZP204 compounds are formulated to offer tough physical properties which are required for sealing pressures up to 10,000 psi during hydraulic fracturing operations. Once hydraulic frac is complete, the unique compound degradation is activated by the water based frac fluids to allow breakdown into flowable, nonclogging particulates, providing multiple benefits to the end user. Degradation can be on the scale of days to weeks, depending on temperature but is not greatly affected by wide range of salinities.

Product Features ZP203 and ZP204

- 80 and 90 Shore A Hardness

- 10ksi Pressure Capability

- Ideal Temperature Range of 130° to 180° F

- Elastomeric Resilience

- Water Activated Degradation

- Tolerant of a Wide Range of Salinities

- Reduces to Non-Clogging Particulates

- Available in Packing Elements, O-Rings, Custom Shapes, and Bonded Profile Seals

Parker’s ZP203 and ZP204 are formulated for an ideal working temperature range of 130°F to 180°F but can be used outside of these if a wider range of degradation time is acceptable. The removal of a drill out step that is required for composite plugs reduces cost of operation, increases rate of return getting the well to production, reduces carbon emissions no longer needing a drill out rig, and results in overall increased safety with fewer personnel on the surface

For more information about Parker ZP203 or Parker ZP204, contact Gallagher Fluid Seals today.