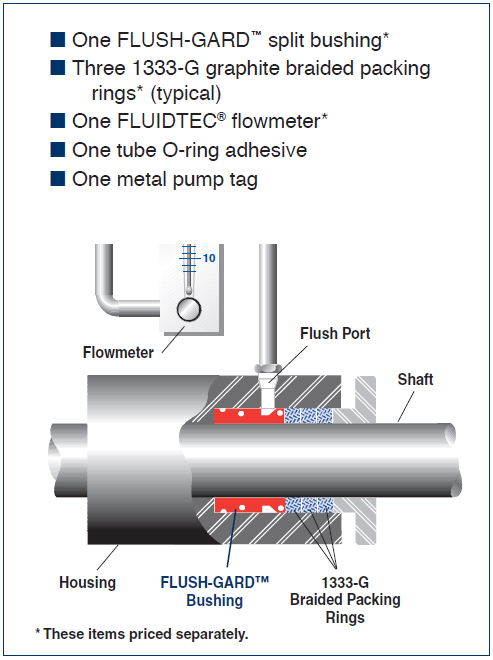

Harmful solids and particulate are contained from entering the stuffing box as the flush water is forced by the FLUSH-GARD™ bushings' unique design - integral tangential multi-porting - toward the pumped media, utilizing the shaft's rotation and centrifugal forces that are created. A small amount is allowed into the stuffing box to lubricate and cool the braided packing.

The axially split design installs quickly, without equipment disassembly, making it an easy retrofit in existing stuffing boxes (typically no re-machining or redesigning required).

Specifications

Material: FLUSH-GARD™ bushing

Carbon graphite-filled PTFE 1333-G : Graphite Braided Packing

Temperature: -250°F (-157°C) to 450°F (232°C)

Surface Speed: To 2,500fpm (12.7 m/s)*

pH Range: 0-14 (except strong oxidizers)

*Above 2,500fpm, consult Garlock or Gallagher Engineering

FLUSH-GARD™ Sealing System

For more information on how to incorporate the FLUSH-GARD™ into your processes, contact us today, and one of our engineers would be happy to solve your most difficult sealing application.