Wiper Seals

GFS Wiper Seals (also known as Scrapers or Excluders) operate to exclude contaminants from entering the sealing system. These contaminants include dirt, mud, dust and moisture. The presence of these contaminants will have a negative impact on the performance of the equipment, and the life of the seals. Poor Wiper Seal performance is amongst the most common causes of premature sealing system failure. Wiper seals function in both a static environment when the equipment is stationary, and dynamically when the cylinder is extending and retracting.

Wipers are designed to be installed in either a stepped or open hardware groove. Wipers installed in open grooves utilize a metal can on the outside of the wiper to ensure a press fit in the groove. Different Wiper Seal profiles offer distinct advantages depending on the sealing application. Temperature, Pressure, Stroke Speed and other environmental considerations would lead users to different profiles and materials. Primary Wiper Seal materials are Polyurethane and PTFE blends. Specific GFS Wiper Seal materials are outlined below.

Wiper Seal applications can be very demanding on the seals. GFS Engineers are available to consult on any Piston Seal application. Click here to contact a GFS Engineer.

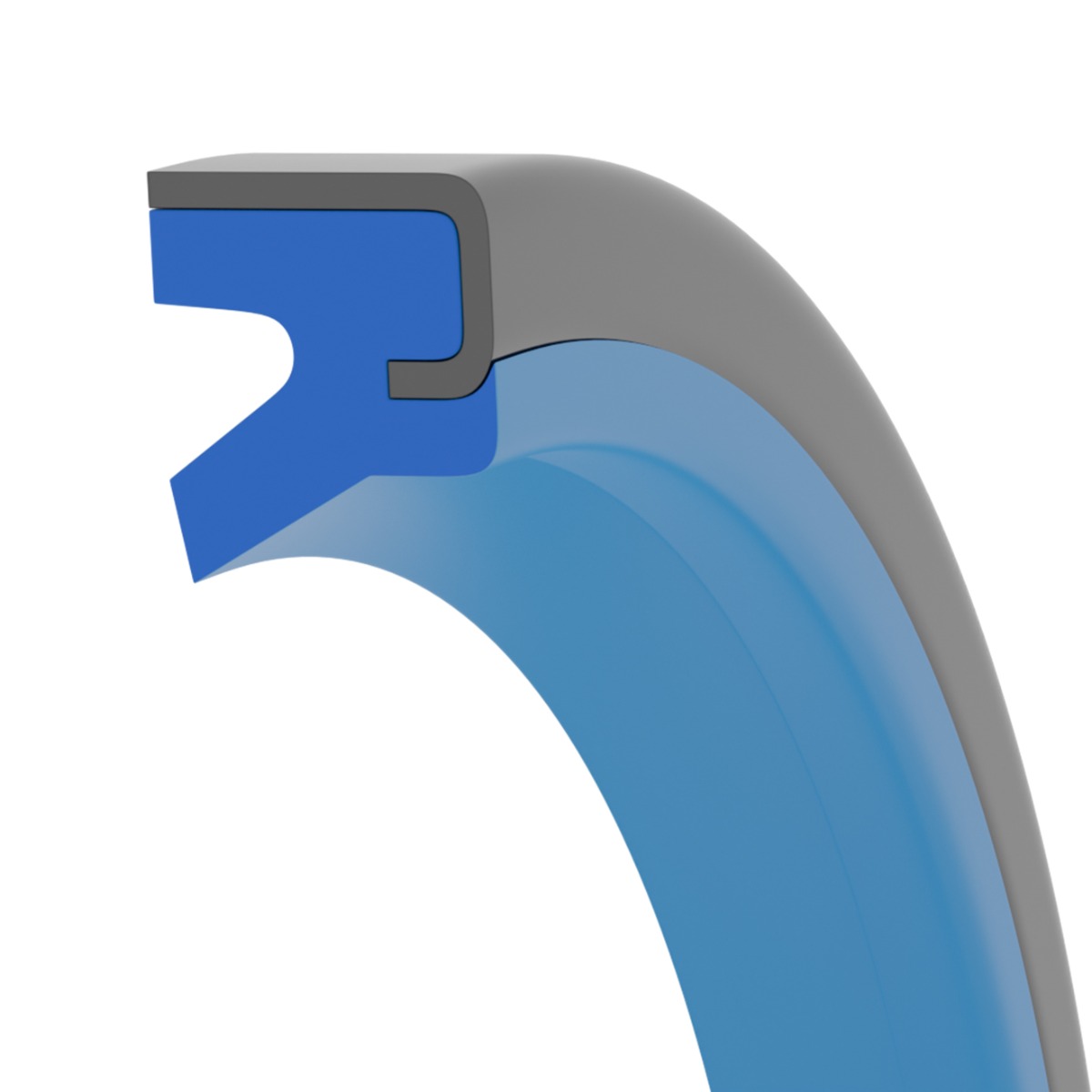

GFS Wiper J Canned

The GFS Wiper J Canned is a single acting metal encased excluder. The Canned J wiper is designed for medium to heavy-duty applications. A press-fit installation prevents OD contamination. The Wiper J Canned is designed with a very aggressive wiping lip, eliminating the entry of environmental elements into the sealing environment. The standard material offering is a 95A durometer polyurethane; additional materials can be supplied upon request.

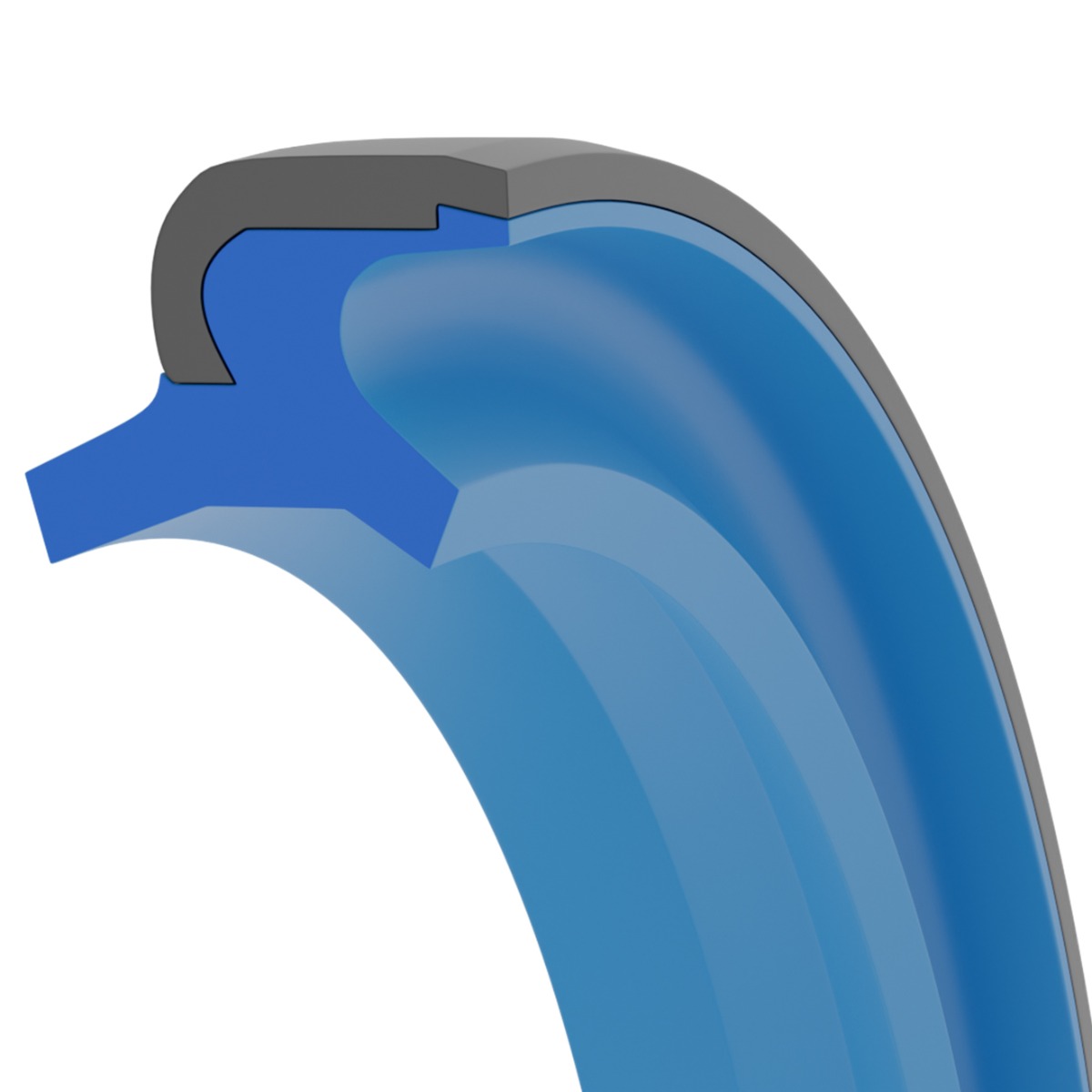

GFS Wiper H Canned

The GFS Wiper H Canned is a double lipped, metal encased excluder. The Canned H wiper can be used in severe applications. A press-fit installation prevents OD contamination. The dual sealing lips work with the primary rod seal to provide redundant leakage control. A vent is typically utilized between the rod seal and the H Wiper to prevent a pressure trap. The standard material offering is a 95A durometer polyurethane; additional materials can be supplied upon request.

GFS Wiper Snap-In AN

The GFS Wiper Snap-In AN is a good choice for light and medium duty hydraulic and pneumatic applications. The snap-in design is over-sized for a secure fit and stability. The wiper is designed to fit standard MS-28776 (MS-33675) dash groove sizes. The geometry of the wiper lip ensures that contact is maintained to the surface of the rod to prevent contaminants from entering the cylinder. The standard material offering is a 95A durometer polyurethane; additional materials can be supplied upon request.

GFS Wiper Snap-In

The GFS Wiper Snap-In is a good choice for light and medium duty hydraulic and pneumatic applications. The snap-in design is over-sized for a secure fit and stability. The wiper is designed to fit standard D housings. The geometry of the wiper lip ensures that contact is maintained to the surface of the rod to prevent contaminants from entering the cylinder. The standard material offering is a 95A durometer polyurethane; additional materials can be supplied upon request.

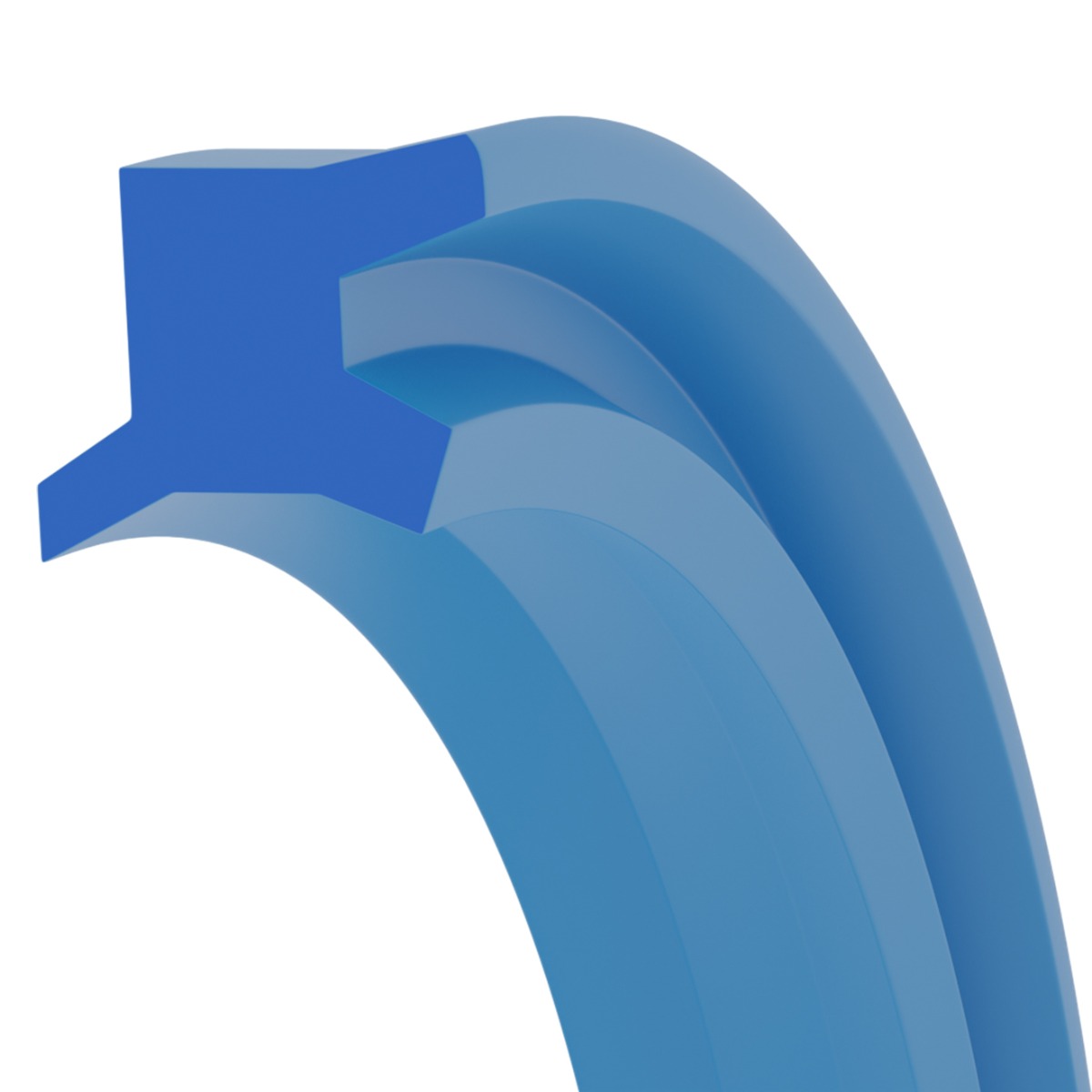

GFS Wiper H

The GFS Wiper H is a double lip excluder and can be used across a wide range of applications. The H wiper can be used in high pressure applications in conjunction with a proper Rod seal, or in lighter pressure applications as both the primary rod seal and wiper. The design minimizes the transfer of hydraulic fluid out of the cylinder when used as a secondary seal. A vent is typically utilized between the rod seal and the H Wiper to prevent a pressure trap. The standard material offering is a 95A durometer polyurethane; additional materials can be supplied upon request.