High-Deflection Seal Design

The high-deflection seal design solves seal leakage from high shaft-deflection and alignment problems.

Seal leakage arises from many different factors including the misalignment of the shaft to the bore centerline, excessive dynamic runout of the shaft, shaft deflection caused by heavy loads, bearing issues, and improper seal installation. Many OEMs of off-road vehicle equipment, lawn-and-garden equipment, and recreational vehicles struggle with the performance of radial lip seals while under the influence of high lip-deflection from these issues.

Evidence of shaft deflection or misalignment in the sealing system appears as heavy, one-sided wear or as an irregular wear-pattern around the circumference of the seal lip. The wear or offset-loads against the seal lip results in severely reduced seal life, higher torque loads, and excessive heat.

High Deflection Axle Seal

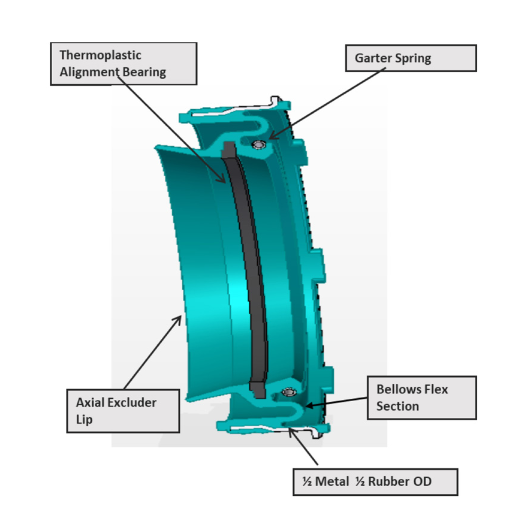

Vanseal’s custom High-Deflection Axle Seal incorporates a bellows between the seal outside diameter (OD) and primary lip, allowing the lip to float radially to accommodate high shaft-to-bore misalignment (STBM) and dynamic-runout (DRO). The design also pairs a half-metal, half-rubber seal OD that successfully retains its original sealing properties within a variety of housing materials.

Vanseal's Design

Our partners at Vanseal have a design that has several key improvements which solve sealing eccentricities and angular offset.

- A bellows flex section backed up by a primary lip containing a special high-temperature thermoplastic bearing which assists with maintaining the correct relationship between the lip’s surface and the shaft.

- An axial excluder lip which prevents contaminant ingress.

- Hydrodynamic aids to support a longer lip life.

Vanseal’s High-Deflection Axle Seal is proven, successfully completing 1,000+ hours of dynamic hot oil bench testing within the individual parameters of an STBM of 1.80mm (.070”) and DRO of 1.0mm (.040”) at 1000 sfpm (5 m/s) and 1750 hrs at combined total eccentricity (STBM + DRO) of 1.5mm (.060”), without leakage.

Their High-Deflection Axle Seal works well in most sleeve bearing applications and assemblies that experience high shaft-deflection or high run-out and misalignment issues. Their seal counters eccentricities three times higher than traditional radial lip seals with STBM of 1.20mm (.050”) and DRO of 1.0mm (.050”); depending on RPM. It also handles operating temperatures between -40 to 300F (-40 - 150C) and can be manufactured using a variety of material compounds, appropriately applicable for a range of fluid compatibilities.

The original article and content can be found on Vanseal's website.

For more information about these High Deflection Axle Seals, contact GFS today.