Hollow Cross-Section Low-Closure-Force Seals Reduce Bolt Loading and Flange Requirements

The need for easy-to-compress, low-closure-force seals is rapidly increasing in many commercial, electronic and communications applications. If you require efficient, reliable seals for light-weight enclosures with minimal bolts, fasteners or latches in combination with thin sheet metal or plastic flanges, consider low closure force (LCF) seals. LCF seals can drastically reduce the amount of closure force (compression) and the resulting stress generated on the sealed components. These hollow cross-sectional seals offer the seal designer and user a low-closure-force sealing solution for many applications. They can be supplied as either:

- Long Length Extrusions

- Spliced Rings/Gaskets

- Cut to Length Extrusions

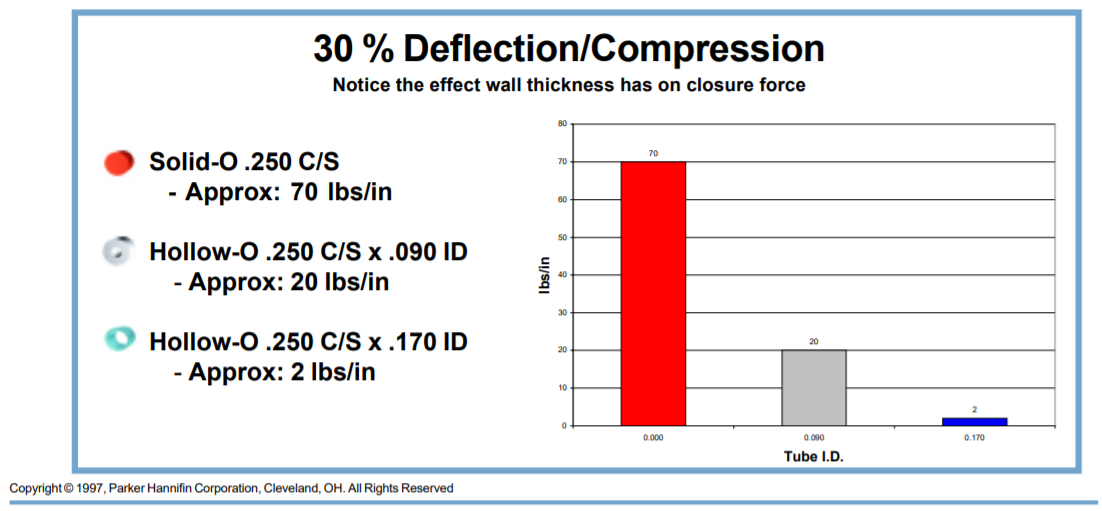

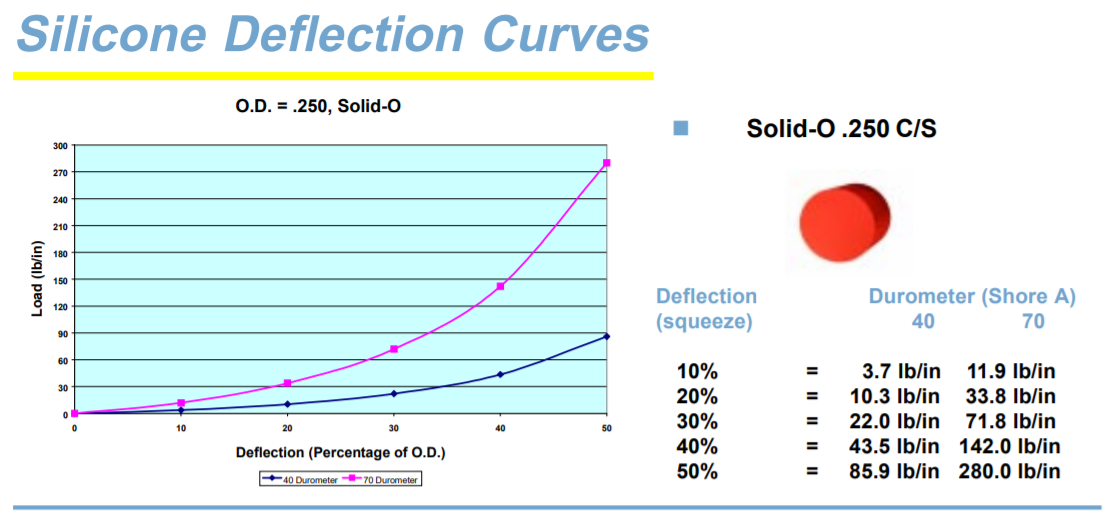

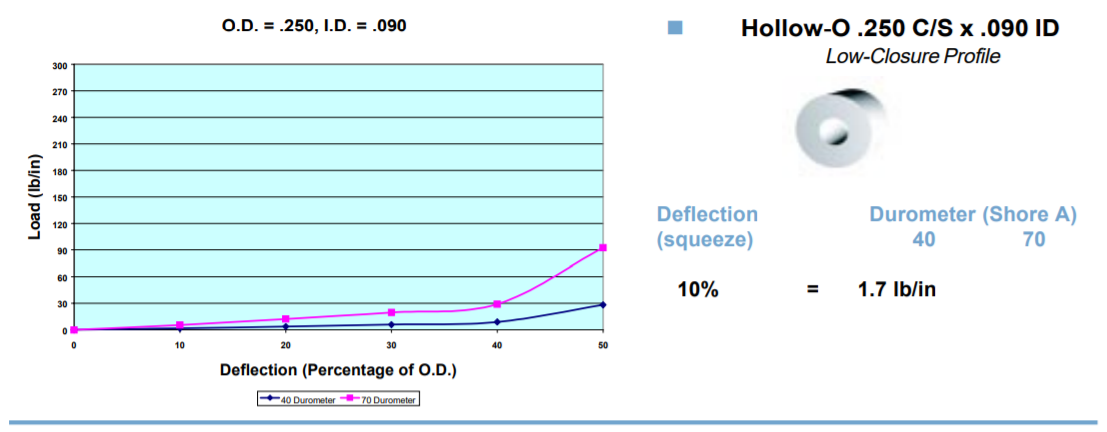

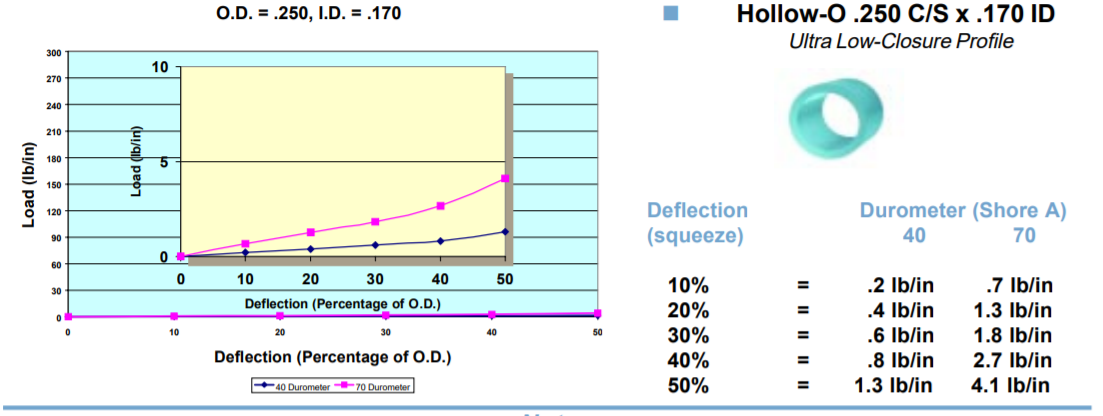

To date, the most common method for reducing closure force has been to reduce the Shore hardness of the elastomeric seal material or change to a foam-type of material. The best method to achieve a dramatic reduction in closure-force is to change from a solid to a hollow cross-sectional profile without lowering the durometer hardness. Controlling wall thickness is key to lowering the lbs/in compression force required.

Our partner at Parker has developed a number of proprietary splicing and bonding methods for joining cord stock and extruded profiles into large diameter O-rings and seals. The graphs below show the benefits of using hollow cross-section low-closure-force seals:

The original article can be found on Parker's website here.

For more information or to request a quote, contact Gallagher Fluid Seals today.