Food, Beverage, and Pharmaceutical Regulations

Component parts that are used in food and drug processing equipment can become damaged by improper installation and/or excessive shear experienced during operation that causes fragments of rubber, plastic, and metal to contaminate ingredients. Chemicals used for cleaning and sterilization of equipment can cause rubber seals to degrade, increasing the probability of particles breaking off and entering the consumable products. Part failures causing product contamination can lead to machine down time, scrap product, product recalls and result in legal problems and negative media attention. All of which have a significant financial impact and can compromise brand loyalty within the market.

Hazard Analysis Critical Control Point (HACCP)

Metal Detectable O-Rings | X-Ray Detectable O-Rings

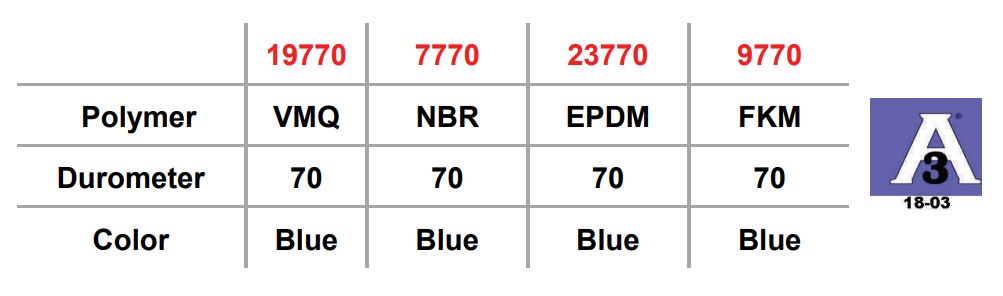

Precision Associates has developed four Metal and X-Ray detectable materials made with ingredients sanctioned under FDA Title 21 CFR 177.2600.

All four materials are 3A Sanitary 18-03 approved and are available in Silicone, Nitrile, EPDM, and FKM. Each is 70 durometer and blue in color. (The industry standard color is blue but materials can be colored for specific customer requirements and any polymer can be made metal detectable).

All compounds were tested by an independent laboratory and found to have magnetic properties that exceed industry standards.

The original article was written by Precision Associates, Inc. and can be found here.

For more information about what Gallagher can offer through Precision Associates, or to talk to a technical sales expert about these materials, contact us today.