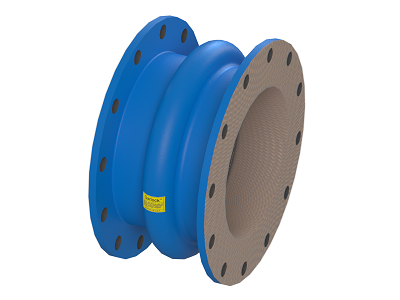

Garlock ABRA-SHIELD™ Expansion Joints

Garlock launched of ABRA-SHIELD™ in 2018, an expansion joint material designed for abrasion resistance and sustainability in demanding high temperature operating conditions.

As the newest addition to Garlock’s family of abrasion resistant expansion joint materials, ABRA-SHIELD™ joined ABRA-LINE® and Natural Rubber to provide a variety of liners that cater to increased abrasion protection. ABRA-SHIELD™ will be an option for use with a number of expansion joint products that Garlock offers – including styles 204, 206, 7250, 8400 and 9394. These expansion joints also provide high levels of protection from stress, misalignment, vibration, noise, shock and corrosion.

In abrasion resistance testing – which provides data to compare materials and predict the lifetime of a material or coating – ABRA-SHIELD™ provided 50% higher abrasion resistance than standard EPDM (ethylene propylene diene monomer rubber). ABRA-SHIELD™ is the recommended solution in abrasive applications (such as slurry, ash and brine) with sustained or spiked temperatures between 180°F and 300°F. For temperatures outside of this range, other materials in Garlock’s family of abrasion resistant expansion joints would be suggested.

This superior performance in challenging environments will be advantageous for applications across a range of industries, including metals/minerals, oil/gas, power generation, pulp/paper, hydrocarbon processing, chemical processing, agrochemical, water/wastewater, mining and fertilizer.

Available ABRA-SHIELD™ Styles

Style 204 Narrow Arch

Ideal for full vacuum applications on the inlet/suction side of a pump. Can be supplied with a filled arch to reduce wear and prevent solids being entrapped. Can be configured in an eccentric or concentric reducing design allowing flanges of unequal size to be connected.

Style 206 EZ-FLO®

Ideal for pressure only applications on the outlet/discharge side of a pump. EZ-FLO® expansion joints contain a single wide flowing arch, eliminating the need for filled arches on slurry services. Its self flushing arch design eliminates media build up and reduces turbulence.

Style 7250 FLEXOMATIC®

Ideal for connections when the main purpose is to reduce noise and vibration in piping systems. The no arch design does not trap solids and can be used in full vacuum applications.

Style 9394

Ideal for low pressure applications that require a high level of flexibility and movement often found in the connections of hoppers, silos, shaker tables, vibratory conveyors, and bowl feeders.

Style 8400

Ideal for low pressure applications with minimal movement.

If you have questions about which style of expansion joint is right for your application, please contact Gallagher's Engineering Department. They'd be happy to walk you through the process of specifying the right sealing solution for your application.