PSA-Backed Seals Replaced by Parker Omega Seal Profile

Article re-posted with permission from Parker Hannifin Sealing & Shielding Team.

Original content can be found on Parker’s Blog.

Customers often call with various sealing challenges. But sometimes their dilemmas can be solved with more robust solutions instead of direct replacements. For example, when a customer is having issues with a PSA-backed hollow seal that keeps peeling away from the bottom surface.

If you need to seal a box with a lid, you may need a 4-corner gasket to seal the contents from dirt and moisture. If you use a solid gasket, the compression force may be too great to effectively close the lid. Using a hollow seal reduces the compression force by orders of magnitude, but it comes with its own set of challenges.

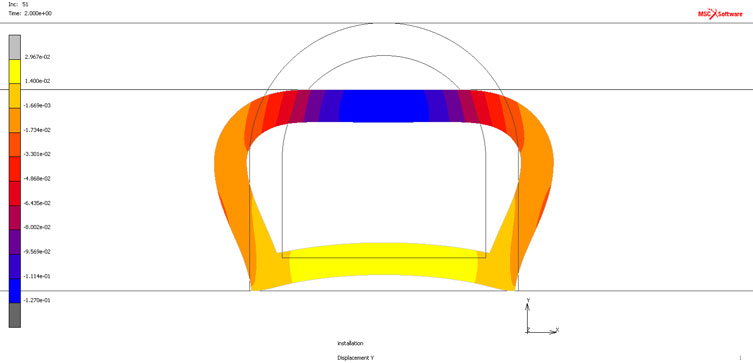

A hollow seal for a box will most often seal between two flat surfaces. The bottom surface will be flat for adhesion to the box, while the top surface is curved to engage the lid as it is seated on top of the seal. However, the disadvantage of this design is the tendency of the flat portion to lift off the bottom surface. Figure 1 illustrates this phenomenon with standard Parfab profile D015.

In the analysis shown in Figure 1, the bowing is 0.030 inch at its highest point. Due to this tendency to bow upward, it is necessary to use Pressure Sensitive Adhesive (PSA) backing to keep the bottom surface in place during compression. However, due to the bowing of this surface, this stresses the PSA backing every time the seal is compressed. This can cause the PSA backing to eventually peel away. When this happens, the seal can also leak due to lack of seal contact on the bottom surface.

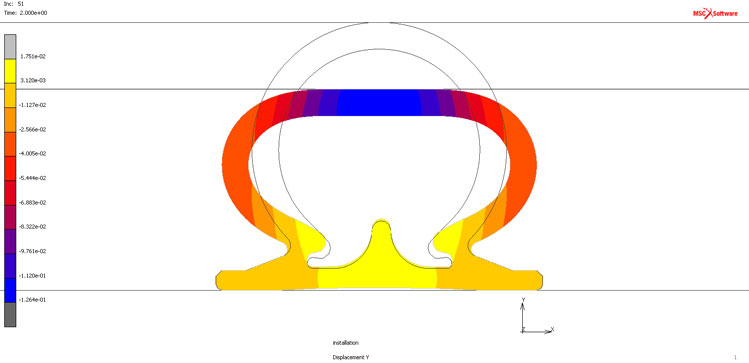

To address this issue, Parker offers the Omega seal profile, which has a hump in the middle of the flat portion to reduce bowing as the seal is compressed.

As shown in Figure 2, the bowing of the bottom surface has been reduced from 0.030 inches to 0.004 inch, which greatly reduces peeling stress when PSA backing is used.

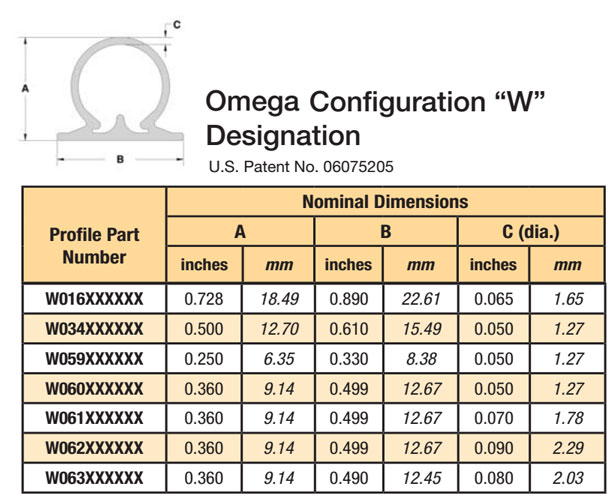

Figure 3 illustrates the standard profiles that Parker offers for the Omega seal profile.

They are also available in a variety of different materials. They can be extruded as cord stock, or supplied as spliced four-corner gaskets for your particular lid or door sealing application.

This article was contributed by David Mahlbacher, Product Design Engineer, Parker O-Ring & Engineered Seals Division.

Source: http://blog.parker.com/robust-sealing-solutions-to-replace-psa-backed-seals