Hardware Recommendations - Static O-Ring Gland Design

What is an O-Ring Gland?

The O-Ring gland (also known as O-Ring groove) is a very important design feature for manufacturing both efficient and cost-effective O-Rings.

The most important consideration for gland design is that it allows for proper and complete compression between the groove and the mating surface. While the shape of the O-Ring relies and depends on the application, shape is generally unimportant. The groove can be a variety of shapes; anything from triangular, rectangular, or dovetail.

Guidelines for O-Ring Gland Design

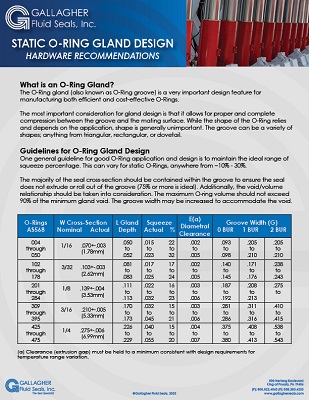

One general guideline for good O-Ring application and design is to maintain the ideal range of squeeze percentage. This can vary for static O-Rings, anywhere from ~10% - 35%.

The majority of the seal cross-section should be contained within the groove to ensure the seal does not extrude or roll out of the groove (75% or more is ideal). Additionally, the void/volume relationship should be taken into consideration. The maximum O-ring volume should not exceed 90% of the minimum gland void. The groove width may be increased to accommodate the void.