Are you suffering from supply chain issues from PCTFE? Victrex CT™ 200 could be a superior alternative for your application.

VICTREX CT™ 200

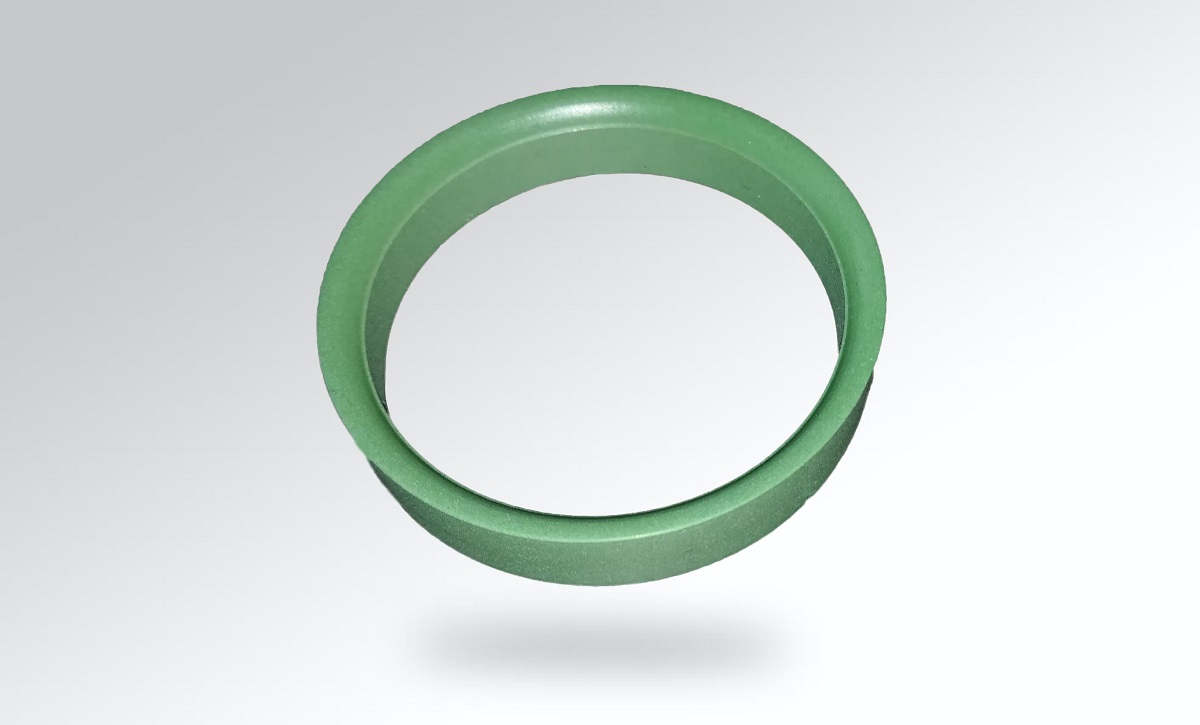

VICTREX CT™ 200 is a high-performance thermoplastic PEEK polymer suitable for dynamic sealing applications at very low temperatures.

As the latest member of the VICTREX CT™ PEEK polymers, the 200 grade series exhibits improved sealing over a wider range of temperatures, compared to commonly used materials such as PCTFE. It does so at low temperatures on account of its greater ductility, and at high temperatures due to its superior creep resistance. It also offers a lower static and dynamic coefficient of friction which helps minimize torque and wear, allowing smaller actuators and saving space and weight.

In addition, laboratory testing indicates that they may require less torque to actuate since they have a lower static and dynamic coefficient of friction compared to PCTFE. This results in less wear, higher performance and a potential for cost savings.

VICTREX CT™ 200 can replace Kel F PCTFE in many sealing applications in cryogenic applications with improved strength, thermal conductivity, superior dimensional stability, and lower coefficient of friction.

Key Benefits of Victrex CT™ 200 over PCTFE

Higher tensile strength than PCTFE coupled with a lower modulus confirms more ductility across a wider range of temperatures; testing at (-320 F / -196 C to 302 F /150 C) indicates better sealing capabilities than PCTFE which would also extend to higher temperatures in the range of 392 F /200 C.

Improved dimensional stability with a Lower and constant coefficient of thermal expansion ensures more dimensional stability and minimizes the shrinkage at low temperatures.

Higher thermal conductivity permits a faster reaction to temperature changes allowing the seat seal to keep interference with the steel counter-surface at all times – contributing to more consistent sealing.

"VICTREX CT 200 possesses the outstanding properties of PEEK, including high strength, and the ability to withstand aggressive chemicals," commented James Simmonite, Director Energy at Victrex. "In particular, we designed the new polymer with a lower coefficient of friction compared to its cousin VICTREX CT™ 100. All of these characteristics put VICTREX CT™ 200 ahead of materials such as PCTFE for cryogenic applications involving gases such as LNG and nitrogen. This is particularly the case in relation to dynamic applications, such as seat inserts, which must remain leak-proof when mechanical movement occurs. VICTREX CT 200 means dynamic progress for the industry."

CT 200 Also Displays Promising Processibility

In addition to its strength and stability, CT™ 200 comes with impressive processibility. This was confirmed during TAT testing, using the Shell Mesc 77/300 standard. CT™ 200 passed the TAT test and verified that it could be used in valve and seating applications.

TAT testing also revealed that the polymer is a candidate for injection molding, compression molding and extrusion processing. With these processibility advantages, CT™ 200 can be rapidly converted into a large number of sealing components. This keeps the cost of each component low and ensures larger production runs are kept on schedule.

With Ongoing Supply Chain Issues, Victrex CT™ 200’s Availability Is Valuable

There’s a reason why PCTFE has been trusted in LNG applications for as long as it has, but there are also reasons to consider a switch to CT™ 200, aside from its superior material properties. If that’s not enough, there’s also supply challenges to consider.

In a post-pandemic world, material shortages are occurring across many industries, and the oil and gas industry is no exception. PCTFE is typically in high demand among O&G processors and operators, and material shortages are making it difficult to affordably acquire it.

That’s not the case with Victrex CT™ 200 as its superior alternative is still off the radar for many oil and gas companies. However, not only is Victrex a better option for cryogenic sealing applications, it is a far easier material to source. That means lower costs and expedited production.

For more information, or to inquire about Victrex, contact Gallagher Fluid Seals today.