The machining of polymers such as PTFE, still remains somewhat of a specialty operation. While there are a plethora of machine shops dotted across the country focused on metal turning and milling operations, few specialize in plastics.

Only someone experienced in metalworking might call machining something like PTFE easy. PTFE is much softer and easier to cut than something like steel or aluminum.

While this certainly is true, polymers present their own unique set of manufacturing challenges, especially when tight-tolerance parts are required. And with Eclipse’s business of aerospace and specialty applications, they almost always are.

Though our partners at Eclipse design and engineer a majority of the parts they manufacture, they still entertain the machining of customer-designed seals and components. But customer prints tend to include dimensional tolerancing not suitable for process capability with PTFE and other polymers.

Calling out a +/-0.001” on a 15” OD isn’t very realistic. Eclipse also sees why in many cases, tight tolerances are not necessary for seal functionality and are likely driving up costs.

To help with your next project, here’s a guide compiled by Eclipse to assist with PTFE and the challenges it can present while manufacturing.

The Inherent Instability of PTFE

PTFE has lots of unique and desirable qualities as a seal material. Its extremely low friction, broad chemical compatibility, and large temperature tolerance make it function where many other materials don’t.

One not-so-desirable property of PTFE is its non-uniform coefficient of thermal expansion over different temperature ranges. And more specifically, the unfortunate large transition it sees at common room temperatures.

The linear coefficient of thermal expansion of PTFE between the temperatures of 65° to 77°F can be more than 5 times higher than the coefficient in only slightly higher or lower temperature ranges. Therefore, a tight tolerance part machined in a room at 70°F will likely measure small if later inspected in a room either 60°F or 85°F.

So, a part received just off the delivery truck in the middle of winter will probably not measure in spec until brought up to room temperature. It's an assumption by our partner at Eclipse that part inspection will be performed at approximately 70°F.

While this jump in thermal expansion might be an inconvenience for part inspection, it can create a significant challenge in the actual machining of the part. Localized heating from the cutting of the material can transition the part into different thermal expansion zones.

This is especially true in very large diameter PTFE parts where it’s not practical to use coolant while turning. A part measured right off the machine will be significantly different than when it’s measured a few minutes later. Eclipse’s experienced machinists are keen on this challenge and know the needed adjustments to produce the correct part.

Measuring Non-Rigid Parts

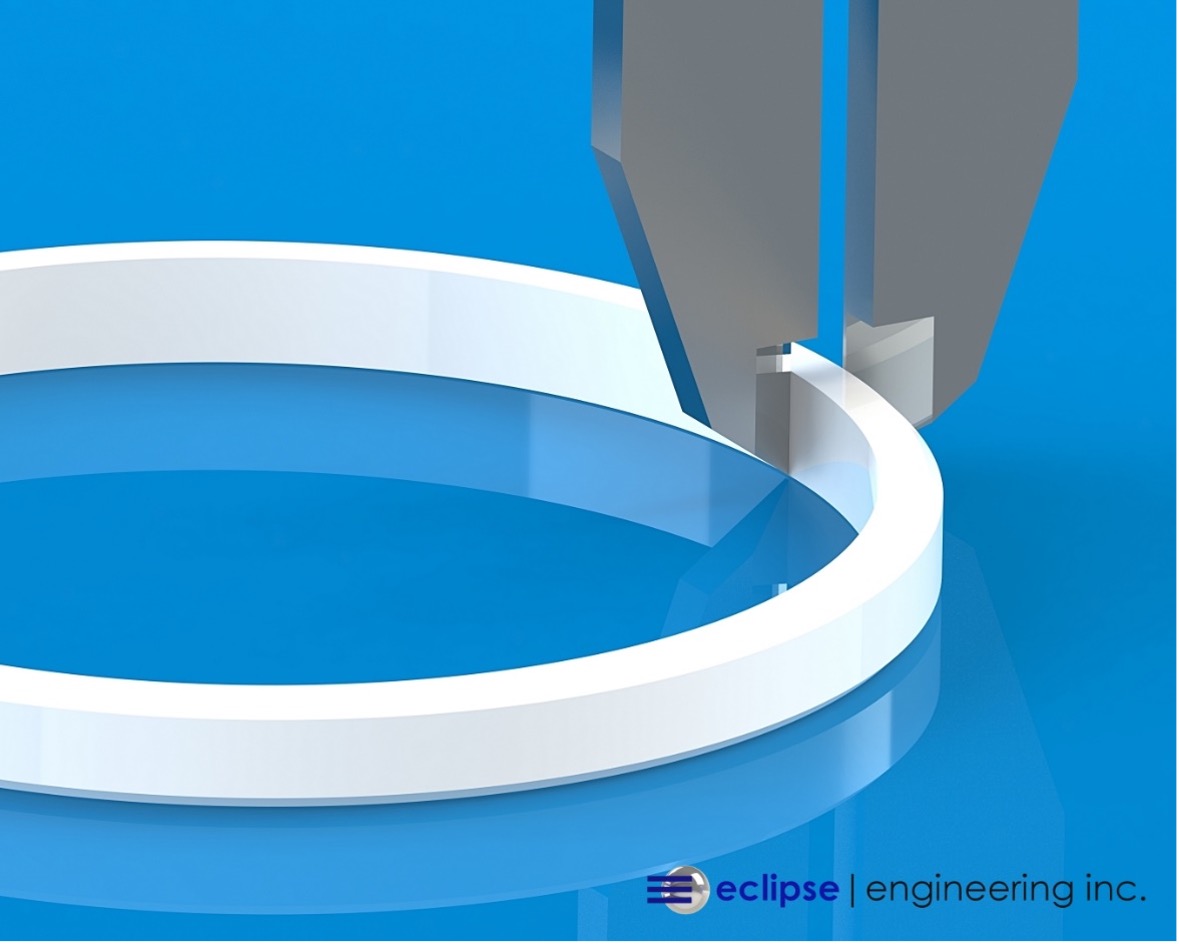

One of the most difficult aspects of machining PTFE parts is the inspection of the parts themselves. Most PTFE seals feature a thin aspect ratio that means the diameter is non-rigid and very flexible.

This presents a challenge when using common measurement tools such as calipers and micrometers. Not only will the part simply flex with any contact pressure, but any out-of-round aspects of the part will be very difficult to account for.

Eclipse uses a Visual Measurement Machine (VMM) to precisely measure diameters. The VMM works much like an optical comparator but can take hundreds of measurements to determine diameter. This provides very accurate measurement and takes into account any out-of-roundness.

While the VMM is a great tool for precise measurements, it’s limited to parts 12 inches in diameter or less. Larger parts become increasing more difficult to measure as the diameter increases.

Eclipse has turned to go/no-go gauges to aid in the measurement of tight-tolerance, thin PTFE parts that are large in diameter. This is the best way to ensure roundness is fully considered while measuring.

Tolerance is What Matters

The diameter of parts is usually the most challenging dimension to hold and inspect, especially for large components. But in most cases, the diameter of PTFE seals is not the most critical dimension for functionality.

Take a standard piston seal ring. The functionality of a seal ring comes from the radial cross-section of the seal compressing the O-Ring beneath it. The squeeze on the O-Ring provides energy to the PTFE ensuring constant contact force with the bore and thus providing a positive seal.

Therefore, the cross-section of the seal is really the most important dimension to hold tightly. Similarly, the cross-section, or lip-to-lip dimension, of a spring energized is what determines the spring compression and general functionality of the seal.

So again, this dimension is predominately the most critical aspect of tolerance.

Fortunately, the cross-section is also the easiest dimension to machine precisely, inspect with common instruments, and is proportionally less affected by any thermal instability. Because of this, Eclipse usually focuses its attention on this dimension rather than diameter.

In the case of products such as standard seal rings, many times these are installed in solid glands. This means the seal must be physically stretched to be installed. It’s not productive to tolerance the diameters needlessly tight if the part is only going to be deformed and resized later.

Tight tolerances, particularly on diameters, can also unnecessarily drive up costs by slowing machine run rates. Yes, the VMM can provide very accurate measurements but it’s also not an “in-process” inspection method. The machinist must stop the lathe and go to the inspection room to get a measurement.

The original article was written by Doug Montgomery, Engineer at Eclipse Seals.

Gallagher Fluid Seals is an authorized distributor for Eclipse Seals. For any PTFE application questions, contact us today.