Variations in grooves can present sealing challenges for many customer applications. The benefits of custom retention seals not only improve improve sealing performance but reduce costs and provide installation efficiency.

Sealing Challenge:

A filter company was using stamped metal end caps that had a deep drawn seal groove. Variation in the size and the round shape of the groove made it difficult to retain the solid molded seal in place with inner diameter stretch alone.

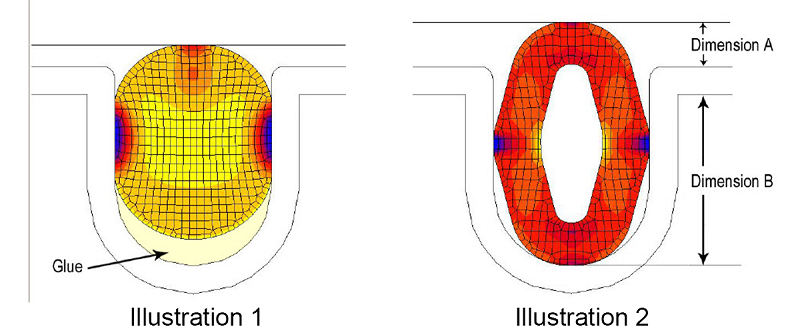

The customer began gluing the existing seal in place to ensure retention. The gluing proved to be a difficult, messy, and time consuming process that added significant cost to the final product. To address these issues and meet the client's needs, Parker OES designed a custom retention seal.

Sealing Solution:

Parker engineers designed a friction-fit hollow profile that retains and effectively seals during transportation and assembly, completely eliminating the need for glue altogether. Through the use of a unique diamond shape, as seen in Illustration 2, the seal compensates for variations in dimensions A and B of the stamped grooves. This hollow profile provides optimal sealing capabilities without increasing the compressive force exerted on the hardware.

To withstand various oil chemistries and high temperatures, Parker selected KA157, an HNBR elastomer, for its exceptional resistance. The innovative hollow diamond seal not only eliminated the gluing process, reducing process costs and increasing installation efficiency, but it also eliminated potential chemical hazards associated with the glue. The implementation of Parker's sealing solution allowed the customer to achieve several significant improvements and cost savings.

Article re-posted with permission from Parker Hannifin.

Original content can be found on Parker’s Website.

For more information about Parker's compounds or sealing applications, contact Gallagher Fluid Seals today.