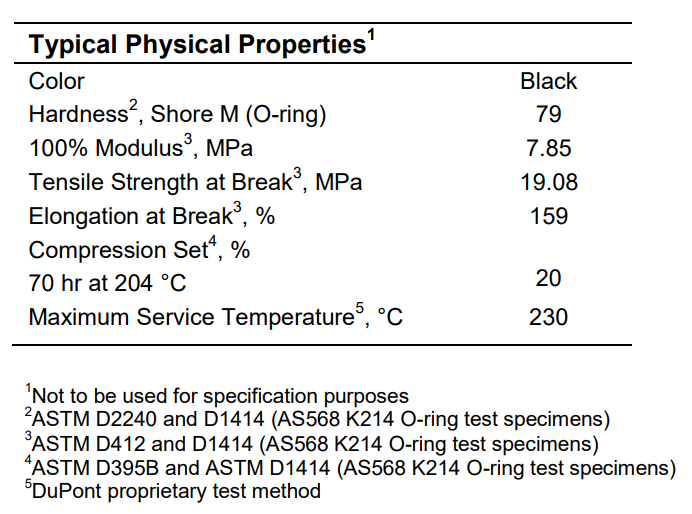

DuPont™ Kalrez® W240 perfluoroelastomer parts are a black product for photovoltaic wet manufacturing processes requiring a wide range of chemical resistance. W240 provides an excellent combination of properties (resistance to acids/bases) and is the product of choice for wet processes as an upgrade from standard elastomers, i.e., FKM, NBR, EPDM, etc. A maximum service temperature of 230°C is suggested.

Suggested Applications for Kalrez W240

- Wet etch tools

- Roller applications for wet inline tools

- Wet chemical management systems

- Filter, pumps, etc., for wet process applications

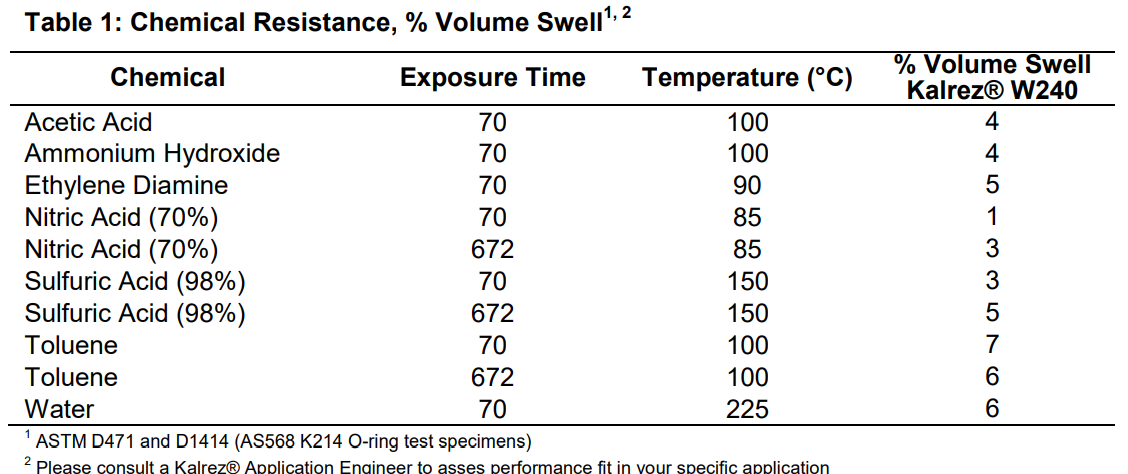

Chemical Resistance of Kalrez W240

For many applications, low volume swell/weight gain (change) of elastomers is critical for proper equipment operation. Excessive swell/weight gain (change) may cause permanent seal failure due to

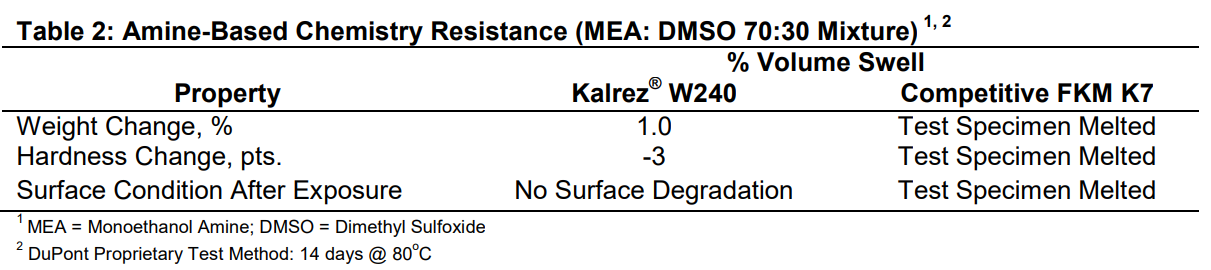

equipment hang-up, extrusion, etc. While other physical property testing may be needed to adequately define product performance in a particular application, volume swell/weight gain (change) is an excellent indicator of resistance to chemical attack. Table 1 provides chemical resistance (% volume swell) test data for Kalrez® W240 in various acids, bases, solvents and water. Table 2 compares the weight gain and volume swell of Kalrez® W240 versus standard FKM in an amine-based chemistry.

For more information about this Kalrez product, or to purchase it, contact Gallagher Fluid Seals today.