Contamination is a major cause of equipment failure, as well as, compromising the performance of an oil. Filtering the oil prior to use and while in use is essential for increasing equipment reliability. Materials that may be used to filter oil are paper, wood pulp, waste, felt and special clays. In most types of filters, the dirty oil is pumped in under pressure and emerges as cleaned oil, leaving the dirt in the filter. There are several types of filters that are used to filter out particles and water. Among these are cartridge filters, cloth, paper and metal, and coalescing filters. Some types of adsorbent filters include activated carbon, Zeolite, Fuller’s Earth and activated alumina.

When beginning the selection process of a filter, use the absolute rating to determine the effectiveness of a filter. The oil passes through the sized opening of the media. In a nominal filter, there is no guarantee that all the pores are the rated size. The term ‘Nominal’ is an arbitrary micrometer value indicated by the filter manufacturer. The Absolute rating is the diameter of the largest hard spherical particle that will pass through a filter under specified conditions. This is an indication of the largest opening in the filter element.

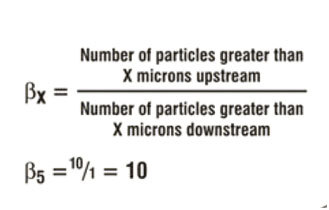

Filters are also selected using the Filtration Ratio (ßx) also known as the Beta Ratio, the ratio of the number of particles greater than a given size (X) in the influent fluid to the number of particles greater than the same size (x) in the effluent fluid. The Beta ratio is the ratio value of particles counted upstream of the filter divided by the number of particles of a given size measured downstream of the filter. The Absolute Filter Rating (Beta Value) considers the element types tested for performance and only useful for same type comparisons. Nominal Efficiency rating is guesswork. The quality value is based on average media poor size (not based on performance). Several key terms to consider include:

- Terminal Pressure Drop: the highest pressure drop across the filter before the filter needs to be changed

- Apparent Dirt Capacity: the amount of dirt that can be added to the filter test system before the terminal pressure drop is reached

- Retained Dirt Capacity: the amount of dirt that is captured by the filter in a test system before it reaches the terminal pressure drop.

- Service Life: the length of time that a filter will survive in an actual system before the filter is plugged. About 800 hours is normally expected for filters on hydraulic systems.

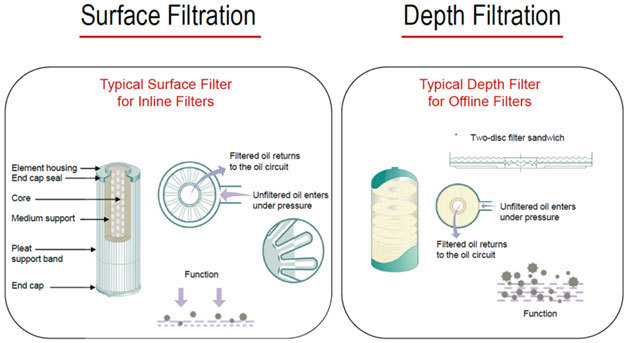

Other than dirt capacity, service life and beta ratio, there are several other factors to consider when choosing a filter. A graded pore filter is one whose pores become smaller near the fluid exit. It is more effective than a filter whose pores are all the same size. At the same time, a fixed pore filter is more effective than a non-fixed pore filter because its fibers are bonded. Non-fixed pore filters are more subject to breakage. The benefit of thinner fibers in a filter is that there are more pores per square inch, which allows higher dirt capacity and lower pressure drop. Also, used filters should be examined for consistent pore sizes, pinholes and good fiber bonding. Full flow filtration allows all the oil from the main pump to flow through the filter. Offline filtration draws off part of the oil from the mainstream and circulates it through a filter. This allows finer filtration without worrying about filter plugging. This is usually done by using a filter cart or attaching the filter to the reservoir.

The following are rules of thumb for the kind of damage that can be caused by different sized particles. Remember that the naked eye can only see particles of 40 microns or higher, so these particles are invisible.

- Particles > 40 micron may cause malfunctions, jamming valves or blocking of orifices/oil channels.

- Solids > 25 micron will typically cause periodic failures because they form lumps that will cause blockage but might flush through with pressure and flow peaks.

- Particles < than 25 microns are the real abrasive and harmful contaminants. Especially silt (2 – 7 micron) small enough to enter the clearances in servo valves or piston pumps.

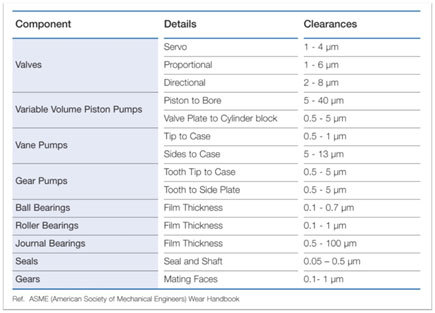

Servo and proportional valves are extremely sensitive to particulate contamination. Contamination can cause slow response and instability, spool jamming/stiction, surface erosion and solenoid burnout. Systems containing servo valves need filters placed directly upstream of the valve. Generally, filters of 3 to 5 microns are used to filter out clearance sized particles. Here are a few typical clearances. Choose filters with micron sizes designed to filter out the following sized particles.

Typical Dynamic Clearances

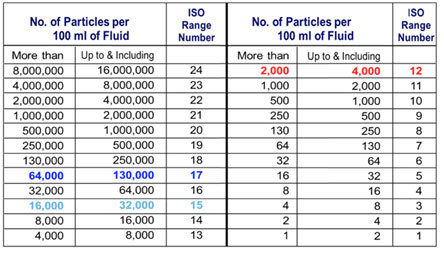

Particulate size and population density can be measured various ways with the data expressed with the ISO cleanliness code ISO 4406, a three-number designation indicating numbers of particles greater than 4, 6 and 14 microns. At each row, the upper limit for each code is approximately double that of the lower limit for the same code. The upper and lower limits are double that of the upper and lower limits of the next lower code.

The unit of measure for particle count data is particles per milliliter of sample. The ISO particle count is only useful if the same type of analytical method is used for each sample. Various types of instruments may produce different values. Also, water as well as trapped air may produce erroneous data. Particle Count is conducted by running a sample through a small orifice with a light source on one side and an optical sensor on the other. The pulse generated by the interruption of the light source is proportional to the size of each particle.

Six particle size ranges are detected. This test requires relatively transparent fluids. Particles come from two sources: wear and contamination. High particle counts indicate potential wear and large particles (greater than 10-15 microns) predict fatigue-oriented catastrophic failure. This test is particularly important in preventing catastrophic failures, since elemental analysis will not detect particles larger than 10 microns. Particle count can help determine that overall cleanliness of the equipment, whether filters are effective, whether abnormal wear is occurring.

Airborne Contamination Control

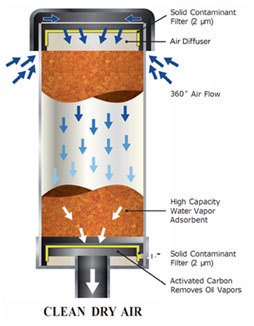

Contamination is responsible for most failure opportunities in a lubricated system. A proven practice to reduce water and particulate contamination is using filters and reservoir air breathers.A reservoir air breather design allows outside air to enter through the 360° opening in the breather's top cap. The top cap design overhangs the body of the breather protecting it from rain, sleet, snow, as well as most equipment wash-down procedures.

When contaminated air enters the top of the breather, it passes through a self-cleaning solid particle filter. This filter traps solid particles greater than 2 micron and keeps them from entering the breather which ultimately wears on your equipment. The filtered air then passes through a bed of silica gel that absorbs moisture in the air. During this step, up to 95% of the water vapor in the air is filtered out.

The filtered air passes through an additional 2-micron filter in the bottom of the breather to ensure that no harmful particles will enter the tank or reservoir. As the color indicating silica gel absorbs moisture it changes from gold to dark green. When the silica gel is adsorbed to its capacity (approximately 40% of its original weight), the breather fully turns dark green. This color change is easily seen and serves as the visual indication that it is time to remove and replace the disposable breather.

It has been determined that more than 75% of all machine wear related failures were due to particulate contaminants. Frequently, the greatest cost of equipment failure is not the component replacement cost, but the labor production downtime. Most particles start off as dirt that becomes airborne, then find its way into lubricant and fuel reservoirs, and are later transported to bearings, bushings, seals, valves, and other machine components. There they become key ingredients in abrasion, erosion, and fatigue failures. The contaminants also cause lubricant degradation, shortening the life of the lubricant and decreasing its ability to lubricate. With machine clearances measured in thousandths of an inch, it does not take much contamination to affect bearings and other sensitive components. Even particles of 10 micron or smaller can disrupt the lubricant film and cause a great amount of wear.

Water Contamination

Water can be found in three phases: free, emulsified, and dissolved. Free water sinks to the bottom of the sump. It should be removed to prevent it from circulating and causing rust. Free water also promotes growth of bacteria and fungus. Emulsified water can be harmful causing rust, oil oxidation and wear. High viscosity fluids form emulsions more readily and permanently than do less viscous fluids. Dissolved water can be in oil up to 250 ppm and can appear clear and bright. The following are considerations for controlling water entry into a system. Prevent wash down water from entering vents and reservoir covers. Install desiccant air breathers or vapor extractors. Properly install and seal covers and hatches. Prevent water from entering new oil by storing drums indoors. If they must be stored outdoors, keep them under a shed or tarp, or store them on their sides with the bungs horizontal at the 3 and 9 o’clock positions. Periodically drain water from low points in system. Environmental condensation will always occur in the tank because of system breathing. Tanks should be stainless steel or coated with an oil resistant paint.

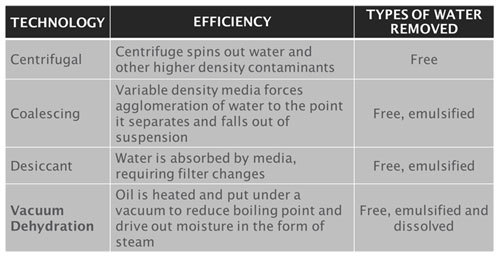

Once sources of water contamination have been controlled to the extent possible, there are several methods to remove water from oil. Methods that can be used successfully for different applications include settling, heat, chemical demulsifiers, filter/coalescers, centrifuges, vacuum dehydrators and electrostatic treatment.

By controlling contamination, the overall longevity and reliability of your equipment will improve dramatically.

Taglines for Contamination Control

- Contamination is a major cause of equipment failure as well as compromising the performance of an oil. Learn what can be done to reduce this from occurring.

- The Absolute Filter Rating (Beta Value) considers the element types tested for performance and only useful for same type comparisons. Learn how to best use this value in your filter selection process.

- Nominal Efficiency rating is considered guesswork. The quality value is based on average media poor size (not based on performance). Learn the several key terms to consider when selecting a filter.

- There is Apparent Dirt Capacity and Retained Dirt Capacity, learn the difference.

- Particles greater than 40 microns may cause malfunctions jamming valves or blocking of orifices/oil channels. Learn the various clearances and what filters would work the best.

- The ISO particle count is only useful if the same type of analytical method is used for each sample. Learn how this value can help increase the life of your equipment.

- It has been determined that more than 75% of all machine wear related failures were due to particulate contaminants. Learn what you can do to reduce this.

- The contaminants cause a decrease in the life of the lubricant and its ability to lubricate. Learn what you can do to offset this from happening.

- Water can be removed from your system using different techniques. Learn how to remove this dangerous contaminant.

- By controlling contamination, the overall longevity and reliability of your equipment will improve dramatically. Learn the various techniques for increasing equipment reliability.

The original article was written by Michael Holloway, President of 5th Order Industry and was featured on Whitmore's website. - Gallagher Fluid Seals is a partner of Whitmore and is an authorized distributor for Dessicant Air Breathers. For more information, contact Gallagher Fluid Seals today.