In May of 2016, a cruise ship went into dry dock for service which included replacing a broken stabilizer. It was determined that the flap bearings from the OEM for the new fin stabilizer would not work, and needed to be replaced. CIP is known for its 24-hour dry-dock emergency support for replacement bearings. When the call came in CIP answered the request for this urgent delivery and provided the bearings the same day!

In May of 2016, a cruise ship went into dry dock for service which included replacing a broken stabilizer. It was determined that the flap bearings from the OEM for the new fin stabilizer would not work, and needed to be replaced. CIP is known for its 24-hour dry-dock emergency support for replacement bearings. When the call came in CIP answered the request for this urgent delivery and provided the bearings the same day!

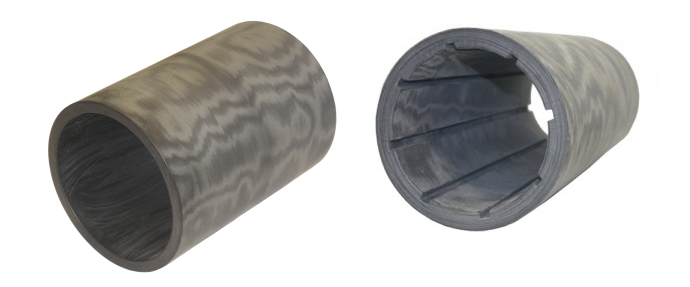

Stabilizer Systems

Oil leakage and lubricant discharges from marine equipment such as fin stabilizers are causing marine operators to find alternative solutions to previous standard grease and oil systems. Although the EPA has provided accommodations allowing the use of environmentally acceptable lubricants (EAL), the better alternative is to replace bearing grease systems altogether with water lubricated materials.

CIP Composite fin stabilizer bearings are water lubricated with the added ability to have axial grooves machined into the bearing, providing better water flow and lubrication. Columbia Industrial Products offer 24 hour emergency support, minimizing dock time. CIP Composites are easily machined onsite and can be freeze fitted or press fitted. Their knowledgeable team can provide technical support for the design calculations for interference and clearance fits for your application.

CIP Composite fin stabilizer bearings are water lubricated with the added ability to have axial grooves machined into the bearing, providing better water flow and lubrication. Columbia Industrial Products offer 24 hour emergency support, minimizing dock time. CIP Composites are easily machined onsite and can be freeze fitted or press fitted. Their knowledgeable team can provide technical support for the design calculations for interference and clearance fits for your application.

CIP Marine™ and CIP 252 are recommended for most marine applications. Contact the Gallagher Engineering Department for help in determining which material is best for your application.

CIP Marine™

CIP Marine is manufactured with polyester textile and a high performance polyester resin with solid lubricants PTFE and molybdenum disulfide (MoS2) evenly dispersed throughout the resin. Typically used as propeller shaft and rudder bushings. CIP Marine is a proprietary material specifically developed for marine environments. This combination of resin reinforced with textile creates a dimensionally stable material ideal for replacing bronze in marine environments.

CIP 252

Proprietary material made specifically for marine environments. Typically used as propeller shaft and rudder bushings and is recommended in sand and silty environments. Manufactured with polyester and PTFE combined textile and a high grade marine polyester resin with the solid lubrication additives PTFE and molybdenum disulfide (MoS2) evenly dispersed throughout the resin. This combination of resin reinforced with textile creates a dimensionally stable material ideal for replacing bronze in marine environments.

Gallagher Fluid Seals is a distributor of CIP Composites full product line. CIP Composites are laminated polymer materials made by impregnating textile with thermoset resins. The physical properties of CIP materials make them superior bearing materials. CIP Composites offer design engineers an attractive, cost effective alternative to the traditional material used for bushings, bearings, wear pads, and thrust washers.