Gallagher Fluid Seals' is happy to present our newest case study for customers who would benefit from reading through a custom FKM seal application.

Our customer is a global leader in the manufacturing of premium residential and commercial venting systems. Their systems and products are designed for ventilation of exhaust gas and other specialty gases.

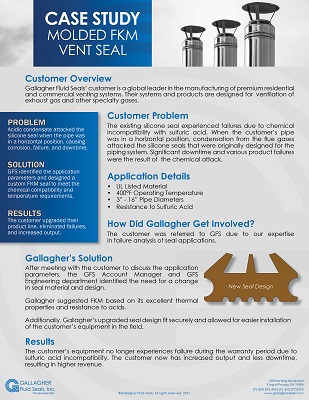

CUSTOMER PROBLEM:

Acidic condensate was attacking the silicone seal when the pipe was in a horizontal position, causing corrosion, failure, and downtime.

How did Gallagher get Involved?

The customer was referred to GFS due to our expertise in failure analysis of seal applications.

Customer Solution

After meeting with the customer, GFS identified the application parameters and designed a custom FKM seal to meet the chemical compatibility and temperature requirements.

The upgraded seal design from GFS fit securely and allowed for easier installation of the customer’s equipment in the field.

Results

The customer’s equipment no longer experiences failure during the warranty period due to sulfuric acid incompatibility. The customer now has increased output and less downtime, resulting in higher revenue.

For more information, check out our full case study.

Have a problem similar to this? Contact Gallagher Fluid Seals today.