Gore Joint Sealant and Gore Gasket Tape Series 500

Created more than 40 years ago, Gore Joint Sealant was the first form-in-place gasket. It was and still is a great sealing solution for steel flanges with large diameters, irregular shapes, or rough/pitted surfaces. It forms a thin yet strong seal when compressed and works in applications where bolt loads are low.

With a reliable, easy install and being a cost-effective sealing method, it's become standard seal for MRO applications all over the world. Installing it is very easy, too: Simply peel off the adhesive backing, apply it to the flange, and overlap the ends. Voila, you have an immediate custom gasket for your unique flange shape.

Looking at Gore Joint Sealant, you may notice it looks strikingly similar to other Gore products, such as Gore 500 Series or Gore 1000. So, what makes them different, and what is the right choice for your application?

The Difference Between Gore Joint Sealant and Gore Gasket Tape Series 500

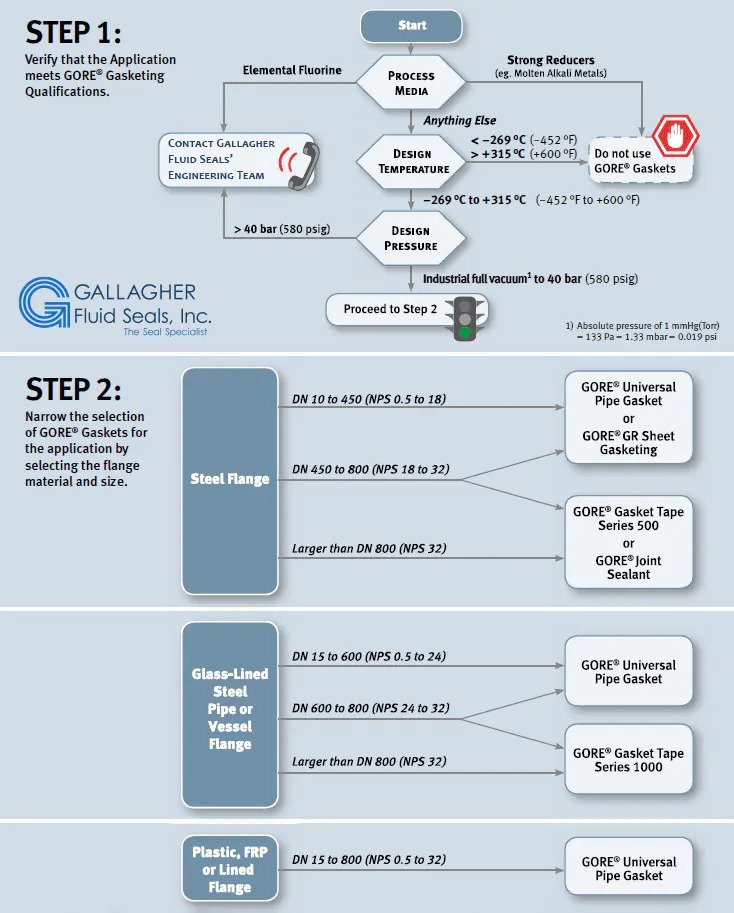

Simply put, the main decision factor for customers looking at Gore Gasket Tape products vs Joint Sealant is thermal performance. Gasket Tape Series 500 Tape has a much more expansive thermal range.

- Gore Joint Sealant's operating range is for temperatures between -60°C to 150°C (-76°F to 300°F).

- Gore Gasket Tape Series 500 has a typical operating range between -60°C to 230°C (-76°F to 445°F).

- It also has a maximum use from -269°C to 315°C (-452°F to 600°F).

- Both products have excellent chemical resistance to all media pH 0-14 except molten alkali metals and elemental fluorine.

Joint sealant's strength is derived from its fibers, not nodes. It's made from 100% expanded PTFE with a monodirectional strength. Gasket Tape Series 500 is also made of 100% ePTFE but has multidirectional strength, making it less "squishy," but much stronger.

For many applications, Joint Sealant would work just fine. For example, the Pulp & Paper industry generally works really well for Joint Sealant applications. There's no need for Series 500 in their flanges due to the nature of processing at the facility. However, more demanding applications typically use the Series 500 or even Series 1000 Tape.

Speaking of Gore Gasket Tape Series 1000, what makes it different than the other two?

The Difference Between Gore Gasket Tape Series 500 and Gore Gasket Tape Series 1000

Gore Gasket Tape Series 1000 is a sealant that is excellent for particularly challenging applications, such as glass-lined steel equipment. Typical users of this product are chemical processors who deal with aggressive media under demanding conditions. These types of applications frequently have challenging and varying conditions - high temperatures, alternating pressures, low gasket loads, or deviations in surfaces. The main thing that differentiates Gore Series 1000 Tape from Gore Series 500 is the proprietary barrier core. This core helps to maintain the seal even at very low loads.

Gore's Gasket Tape Series 1000 has an engineered core to amplify the available load. This helps create a seal more than 10X tighter than other ePTFE gasket tapes. Because of this, it delivers exceptional sealing reliability over time and process cycles relative to other ePTFE gasket tapes. It allows for more uptime and runtime periods, enabling longer maintenance cycles.

No matter the type of process media - - Gore has a solution to help you quickly seal challenging applications.

Gallagher Fluid Seals is an authorized distributor of Gore products, which include Joint Sealant, Gasket Tapes, UPG gaskets, and more. For more information or to see if Gore might be a good fit for you, contact us today.